A split-type electric Fenton equipment and its method for efficiently treating coal chemical wastewater

A split-type, equipment technology, applied in natural water treatment, chemical instruments and methods, centrifugal separation of water/sewage treatment, etc. problems, to achieve the effect of great difficulty, reducing the content of pollutants, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

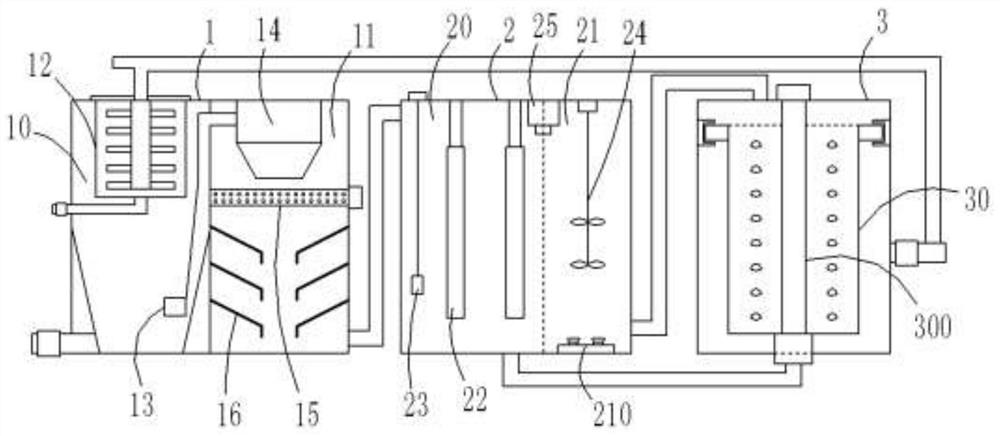

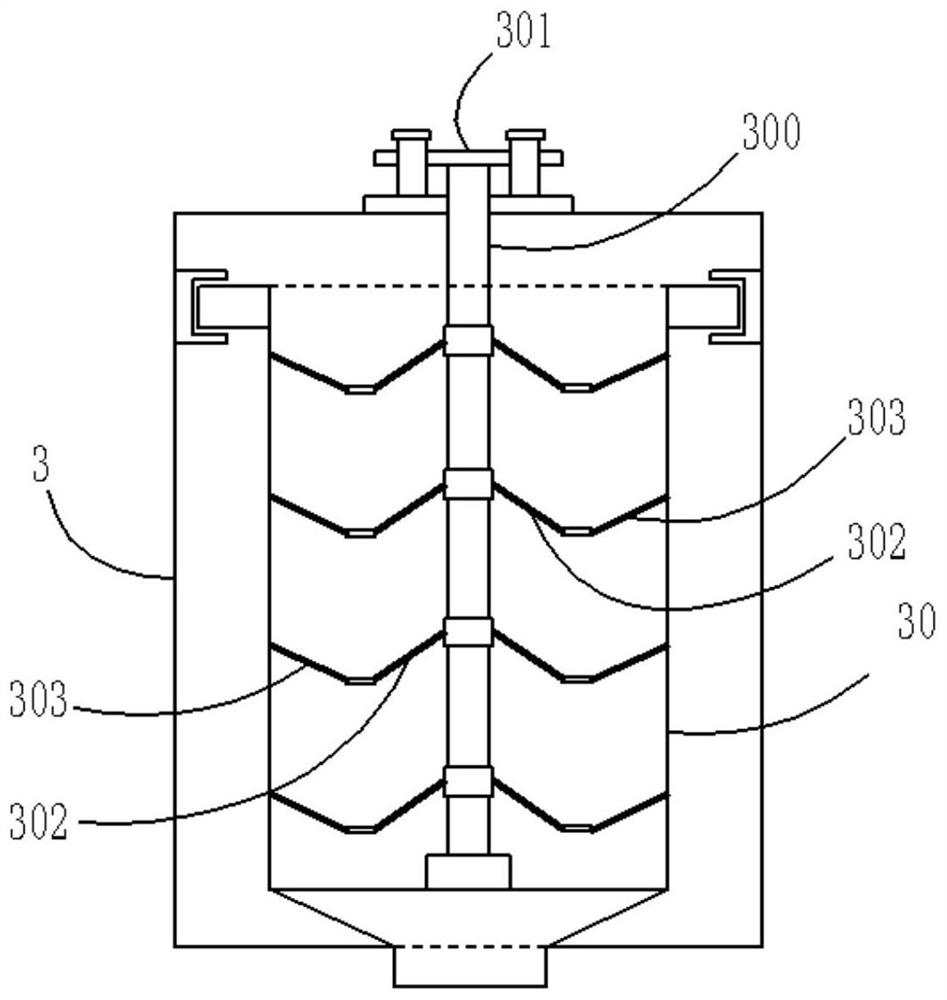

[0026] Embodiment 1: as figure 1 , 2A split-type electric Fenton device shown includes a pretreatment tank 1, an electrolytic reaction tank 2, a sedimentation tank 3, a control device and a power supply device; the pretreatment tank 1 includes a filter chamber 10 and an oil and sulfur removal chamber 11, and the filter The cavity 10 and the oil and sulfur removal cavity 11 are arranged side by side in the pretreatment tank 1. The upper end of the filter cavity 10 is provided with a liquid inlet pipe. The inside of the filter cavity 10 is provided with a grid box 12. The grid box 12 is connected with the liquid inlet tube. A primary slag discharge pipe is provided on the grid box 12, and the primary slag discharge pipe runs through the pretreatment tank 1; a wedge-shaped block is provided at the bottom of the filter chamber 10, and a secondary slag discharge pipe is provided on the filter chamber 10, and the filter chamber 10 is provided with a Suction pump 13, a swirler 14 is...

Embodiment 2

[0035] Embodiment 2: as figure 1 , 2 A split-type electric Fenton device shown includes a pretreatment tank 1, an electrolytic reaction tank 2, a sedimentation tank 3, a control device and a power supply device; the pretreatment tank 1 includes a filter chamber 10 and an oil and sulfur removal chamber 11, and the filter The chamber 10 and the oil and sulfur removal chamber 11 are arranged side by side inside the pretreatment tank 1, the upper end of the filter chamber 10 is provided with a liquid inlet pipe, and the inside of the filter chamber 10 is provided with a grid box 12, which is connected to the liquid inlet pipe. The grid box 12 is provided with a primary slag discharge pipe, the primary slag discharge pipe runs through the pretreatment tank 1, a wedge-shaped block is provided at the bottom of the filter chamber 10, a secondary slag discharge pipe is provided on the filter chamber 10, and the filter chamber 10 is provided with a There is a suction pump 13, and a swi...

Embodiment 3

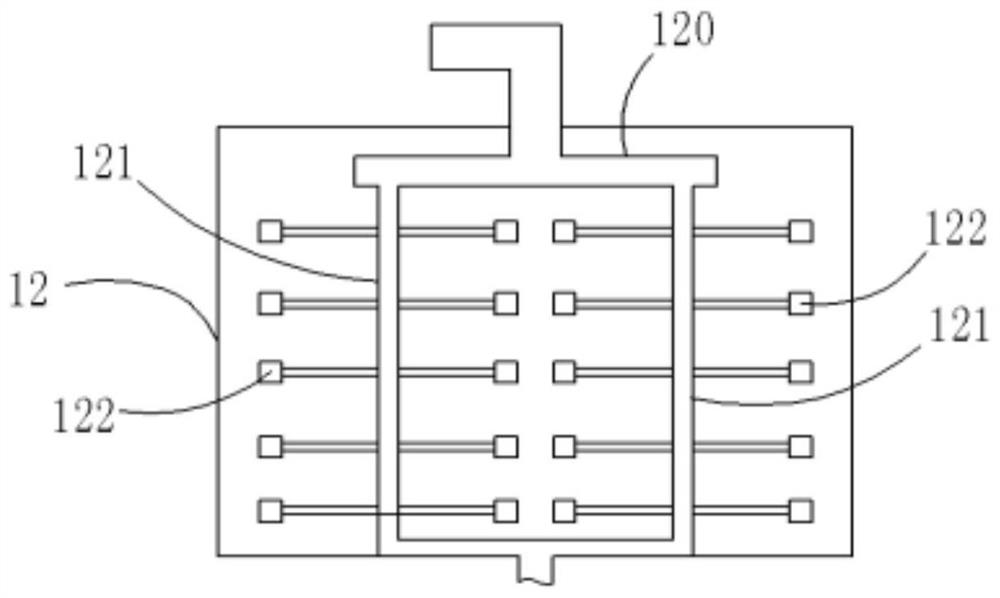

[0044] Embodiment 3: as figure 1 , 2A split-type electric Fenton device shown includes a pretreatment tank 1, an electrolytic reaction tank 2, a sedimentation tank 3, a control device and a power supply device; the pretreatment tank 1 includes a filter chamber 10 and an oil and sulfur removal chamber 11, and the filter The chamber 10 and the oil and sulfur removal chamber 11 are arranged side by side inside the pretreatment tank 1, the upper end of the filter chamber 10 is provided with a liquid inlet pipe, and the inside of the filter chamber 10 is provided with a grid box 12, which is connected to the liquid inlet pipe. The grid box 12 is provided with a primary slag discharge pipe, and the primary slag discharge pipe runs through the pretreatment tank 1. A main pipe 120 is installed horizontally inside the grid box 12, and the main pipe 120 is connected with the liquid inlet pipe. Branch pipes are vertically arranged at both ends of the main pipe 120. 121, each branch pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com