Waterborne epoxy resin modifier for emulsified asphalt and preparation method and application method thereof

A technology of water-based epoxy resin and emulsified asphalt, which is applied in building components, building insulation materials, construction, etc., can solve the problems of poor compatibility between water-based epoxy resin and emulsified asphalt, slow demulsification speed, and low high-temperature drawing strength , to improve storage stability, prevent gelation, enhance tensile and shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

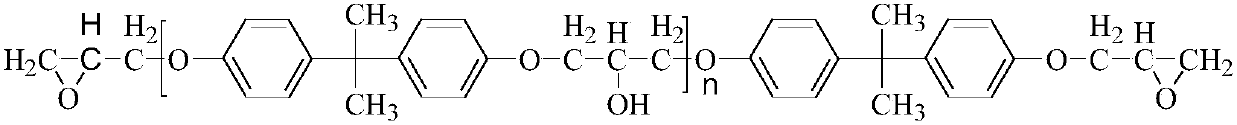

Method used

Image

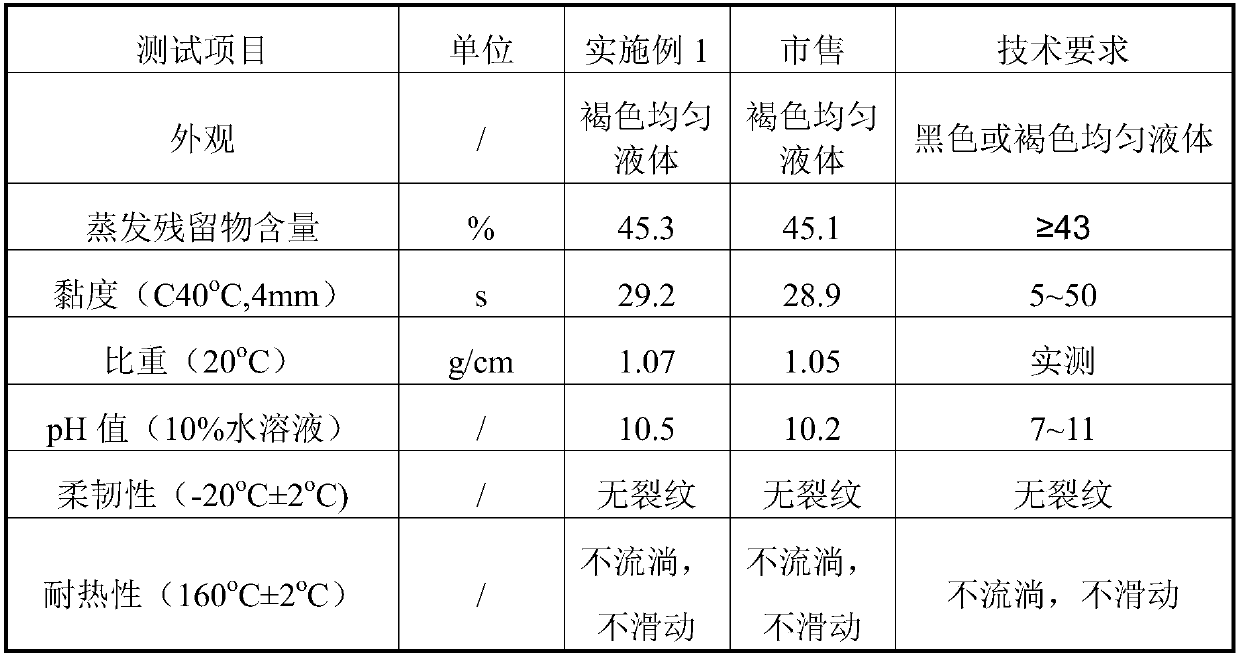

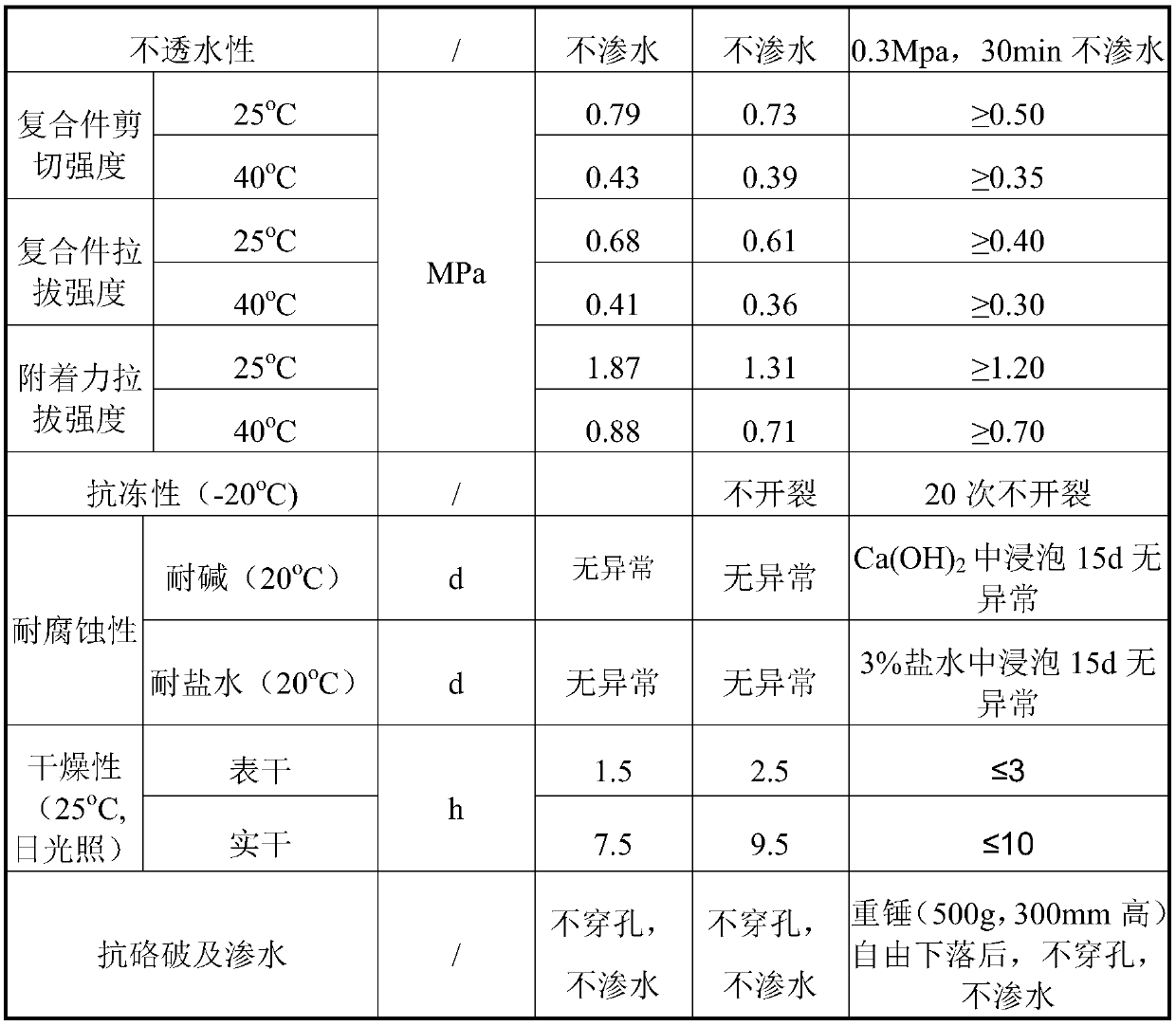

Examples

Embodiment 1

[0037] S1. 15g ethylene glycol butyl ether is joined in 30g bisphenol A epoxy resin, then adds 0.3g lauroyl peroxide to reaction system;

[0038] S2. Add 6g of methacrylic acid to the reaction system, raise the temperature to 108°C, and react for 3h to obtain the graft copolymer intermediate;

[0039] S3. Then cool the intermediate to 60°C, add 1.5g of ammonia water and 30g of deionized water and stir for 1h;

[0040] S4. After returning to room temperature, add 0.006 g of di-tert-butyl dicarbonate to introduce tert-butoxycarbonyl to obtain the target product.

[0041] The grafting rate of the intermediate was measured by the methanol hot-melt cold analysis separation method to be 41.3%, and the median particle diameter of the water-based epoxy resin emulsion was measured by a laser particle size analyzer to be 955nm.

[0042] Preparation and spraying of water-soluble epoxy asphalt:

[0043] Take 5g of new water-based epoxy resin, compound 0.005g of dicyandiamide, add it to ...

Embodiment 2

[0050] S1. 20g n-butanol is joined in 30g bisphenol A epoxy resin, then add 0.3g lauroyl peroxide to reaction system;

[0051] S2. Add 7.5g of methyl methacrylate into the reaction system, raise the temperature to 115°C, and react for 4h to obtain the graft copolymer intermediate;

[0052]S3. The temperature of the intermediate was lowered to 70°C, and 4.2g of N-N dimethylethanolamine and 60g of deionized water were stirred and reacted for 1.5h;

[0053] S4. After returning to room temperature, add 0.011 g of benzyl chloroformate to introduce benzyloxycarbonyl to obtain the target product.

[0054] The grafting rate of the intermediate was measured by the methanol hot-melt cold analysis separation method to be 49.3%, and the median particle diameter of the water-based epoxy resin emulsion was measured by a laser particle size analyzer to be 220nm.

[0055] Preparation and spraying of water-soluble epoxy asphalt:

[0056] Take 20g of new water-based epoxy resin, compound 0.08...

Embodiment 3

[0063] S1. 18g isopropanol is joined in 30g bisphenol A epoxy resin, then adds 0.4g tert-butyl hydroperoxide to reaction system;

[0064] S2. Add 8.0 g of butyl acrylate to the reaction system, raise the temperature to 110° C., and react for 5 hours to obtain a graft copolymer intermediate;

[0065] S3. Then cool the intermediate to 50°C, add 4.0g N-N dimethylethanolamine and 50g deionized water and stir for 1h;

[0066] S4. After returning to room temperature, add 0.042 g of methoxycarbonyl chloride to introduce the methoxycarbonyl group to obtain the target product.

[0067] The grafting rate of the intermediate was measured by the methanol hot-melt cold analysis separation method to be 44.3%, and the median particle size of the water-based epoxy resin emulsion was measured by a laser particle size analyzer to be 320nm.

[0068] Preparation and spraying of water-soluble epoxy asphalt:

[0069] Take 10g of new water-based epoxy resin, compound with 0.03g of triphenylphosphi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com