Flame-retardant polyester and preparation method thereof

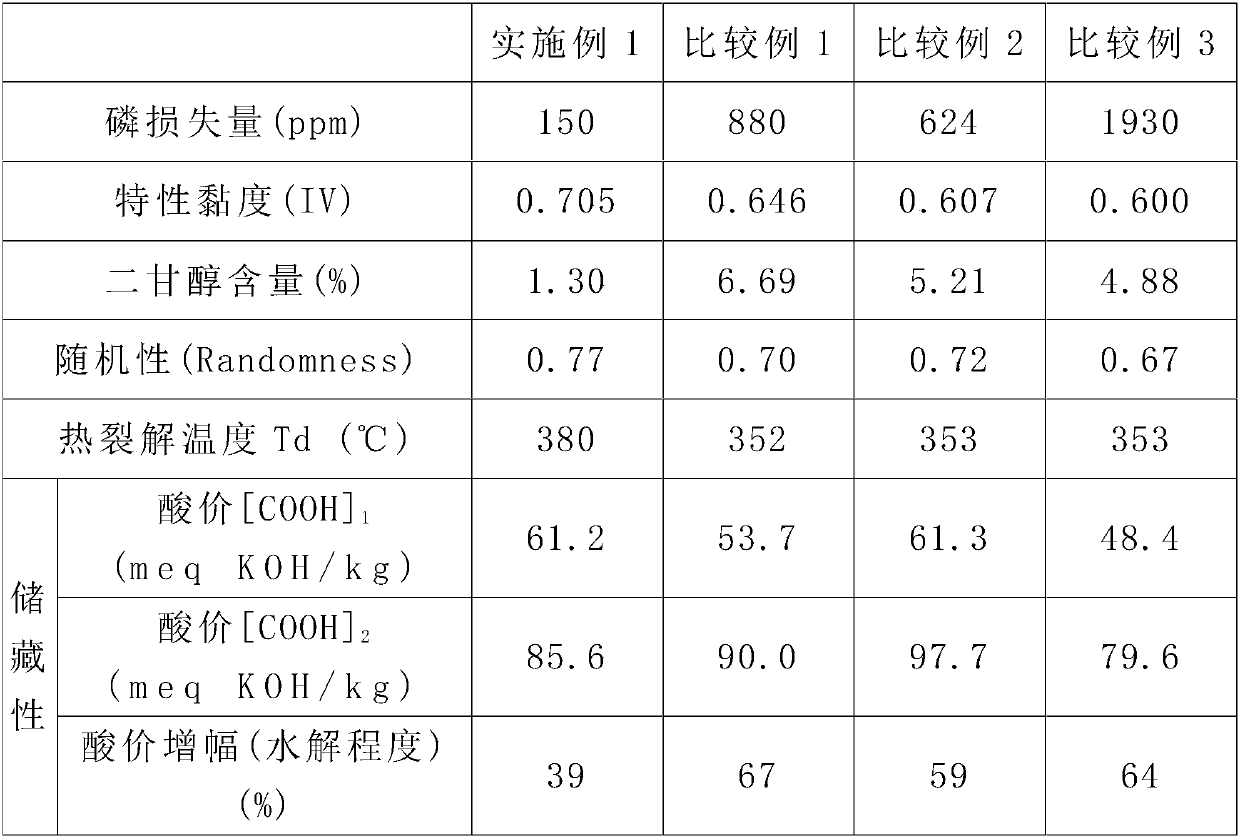

A technology of flame retardant polyester and esterification, applied in the field of flame retardant polyester, which can solve the problems of high phosphorus loss and poor thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

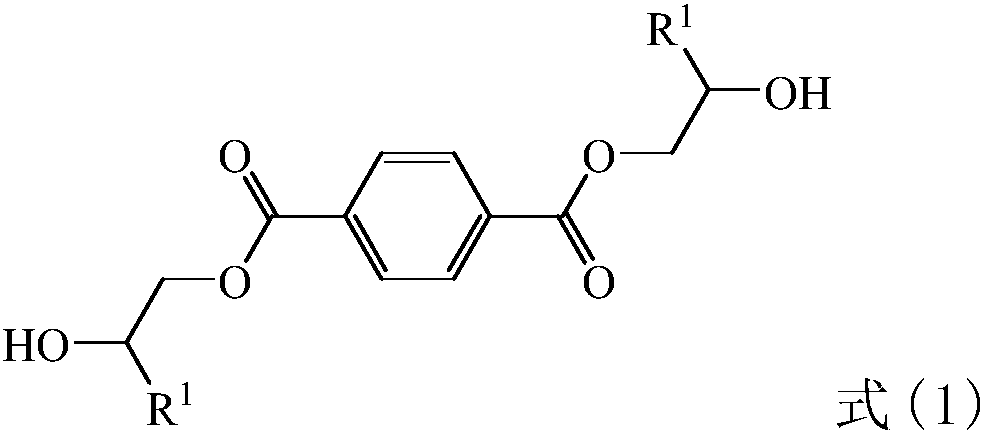

Method used

Image

Examples

Embodiment 1

[0039] In a 1 liter reactor, 280.6g (1.1mole) of bis-ethylene terephthalate powder (manufacturer is sigma-aldrich), 84g (0.5mole) of terephthalic acid, and 36.2g (0.17mole) of 2-carboxyethylphenylphosphinic acid (the 2-carboxyethylphenylphosphinic acid contains 14.47wt% phosphorus element), to obtain a composition. Nitrogen is fed into the reactor until the pressure of the reactor is 0.5 to 1 kg / cm 2 to replace the air in the reactor. Afterwards, in a nitrogen environment, under the conditions of normal pressure and 250°C reaction temperature, the composition was subjected to esterification reaction until the esterification rate of the esterification reaction was 84%, and an esterification product was obtained. Then, 0.105g of antimony trioxide and 0.525g of phosphoric acid in ethylene glycol solution (the concentration of phosphoric acid is 5wt%) were dropped into the reactor, and under the condition that the reaction temperature was 275°C, the ester The polycondensation pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com