Method and device for refining caprolactam

A technology of caprolactam and refining method, which is applied in the field of caprolactam production, can solve the problems of many process steps and high process energy consumption, and achieve the effect of simple process, high purity and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0036] According to one embodiment of the present invention, the method comprises: crystallizing the crude caprolactam product in the presence of a crystallization solvent to obtain caprolactam crystals, and then performing rectification on the caprolactam crystals, wherein the crystallization solvent contains Solvent A and solvent B, the solvent A is selected from at least one of aromatic hydrocarbons and / or alcohols, and the solvent B is selected from at least one of halogenated hydrocarbons, ethers and alkanes with 6-12 carbon atoms, preferably For alkanes with 6-12 carbon atoms, the mass ratio of solvent A to solvent B is 1:(1-50).

[0037] Since the solubility of caprolactam in alkanes is smaller than that in halogenated hydrocarbons and ethers, in order to further improve the yield of caprolactam, the preferred solvent B is at least one of the alkanes with 6-12 carbon atoms, more preferably It is at least one of alkanes with 6-9 carbon atoms.

[0038] In the present inv...

Embodiment 1

[0123] This example is used to illustrate the refining method and device for caprolactam provided by the present invention.

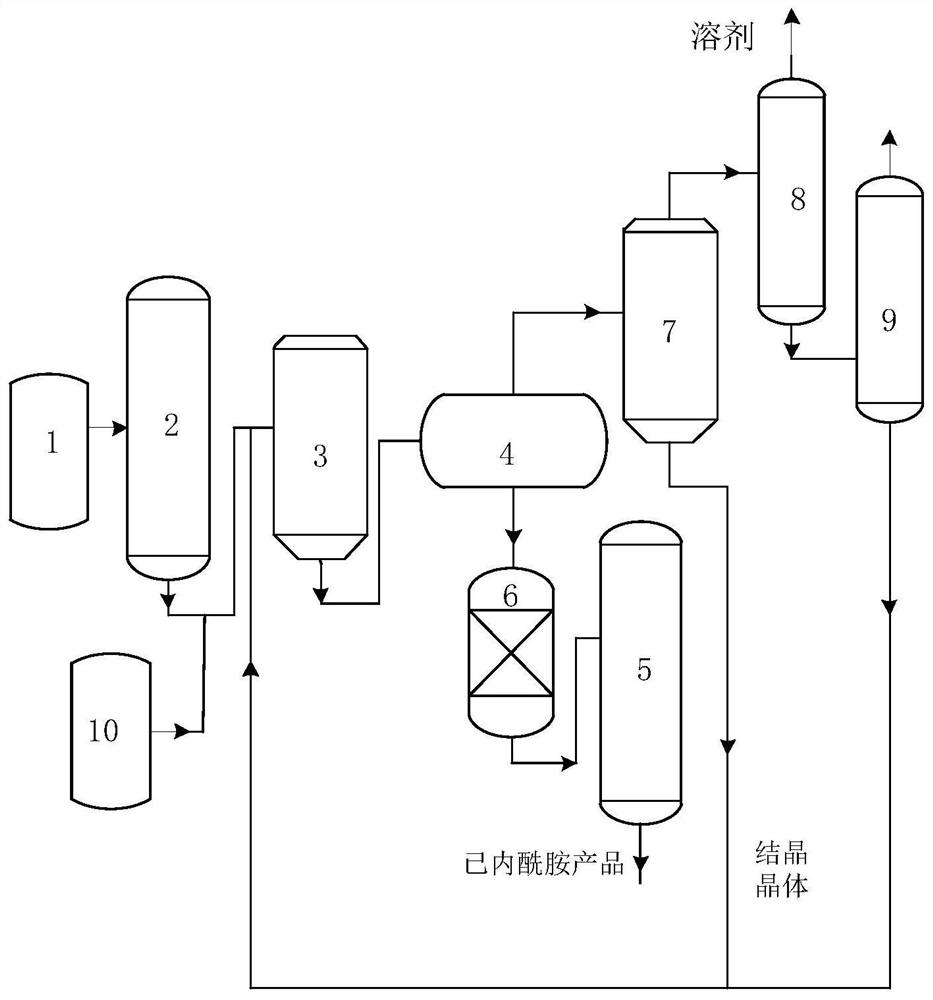

[0124] This example is in figure 1 performed on the device shown.

[0125] (1) Cyclohexanone oxime liquid phase Beckmann rearrangement reaction, liquid ammonia neutralization, benzene extraction, obtain the solution of caprolactam crude product and benzene, store in the first storage tank 1, wherein, the content of caprolactam crude product is 17.5% by weight , the main composition of caprolactam crude product is: the caprolactam of 99.8460% by weight, the cyclohexanone of 454ppm, the cyanocyclopentane of 53ppm, the cyclohexenone of 21ppm, the 3-methylaniline of 8ppm, the aniline of 13ppm, the aniline of 218ppm Cyclohexanone oxime, 15ppm n-pentanamide, 25ppm octahydrophenazine, 82ppm 1,5,6,7-tetrahydroazepin-2-one and other unidentified impurities.

[0126] (2) Send the solution of the caprolactam crude product of step (1) and benzene to distillation ...

Embodiment 2

[0142] This example is used to illustrate the refining method and device for caprolactam provided by the present invention.

[0143] This example is in figure 1 performed on the device shown.

[0144] According to the method of Example 1, a solution of crude caprolactam and benzene with a crude caprolactam content of 17.5% by weight was obtained.

[0145] (2) Send the solution of the caprolactam crude product of step (1) and benzene to distillation tower 2, carry out distillation under normal pressure, remove a large amount of benzene, obtain the mixture of benzene content 10% by weight at the bottom of distillation tower 2;

[0146] (3) the mixture of the benzene content 10% by weight that step (2) obtains is sent into the crystallizer 3 (OSLO crystallizer), and is passed into the normal heptane ( The n-heptane is provided by the second storage tank 10), and evaporated and crystallized at a temperature of 20° C. to obtain a crystalline product;

[0147](4) Same as Example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com