Copper indium gallium selenium absorption layer prepared by non-vacuum method without selenizing process

A copper indium gallium selenide, non-vacuum technology, applied in the fields of final product manufacturing, sustainable manufacturing/processing, photovoltaic power generation, etc., can solve problems such as toxicity and complex process hazards, achieve mild reaction, stable film structure, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

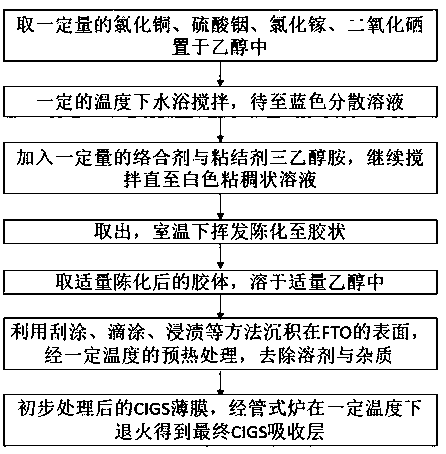

[0017] Specific embodiment 1, a copper indium gallium selenium absorption layer prepared by a non-vacuum method in the non-selenization process of the present invention is carried out according to the following steps:

[0018] One, the preparation of copper indium gallium selenide colloid: take copper chloride, indium sulfate, gallium chloride, selenium dioxide as Cu source, In source, Ga source, Se source, according to (Cu:In:Ga:Se=1: 1.4:0.6:4) molar ratio dissolving in ethanol solvent, adding triethanolamine as a complexing agent and binder, stirring in a water bath at a certain temperature (40-70°C) to a white solution, volatilizing and aging to white at room temperature gelatinous, ready to use;

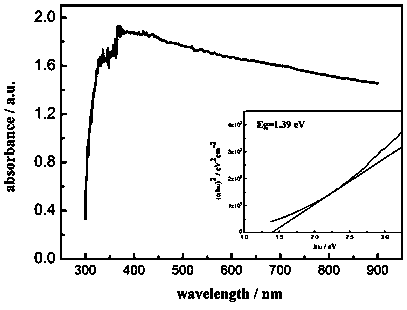

[0019] 2. Preparation of copper indium gallium selenide precursor thin film: take an appropriate amount of colloid and dissolve it in ethanol, apply it on the substrate by scrape coating method or drop coating method, and remove the solvent and impurities through preliminary hea...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment differs from Embodiment 1 in that the substrate described in step 2 is fluorine-doped tin dioxide conductive glass, copper sheet, and steel sheet.

specific Embodiment approach 3

[0022] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the colloidal thickness of the coating film in the preparation of the CIGS precursor film described in step 2 is 25-95 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com