Pichia kudriavzevii embedded tea polyphenol microcapsules and preparation method thereof

A technology of microcapsules and tea polyphenols, applied in the field of preparation of microcapsules, can solve the problems of high-efficiency embedding of tea polyphenols, low embedding efficiency, low embedding rate, etc., achieve low cost, improve stability, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

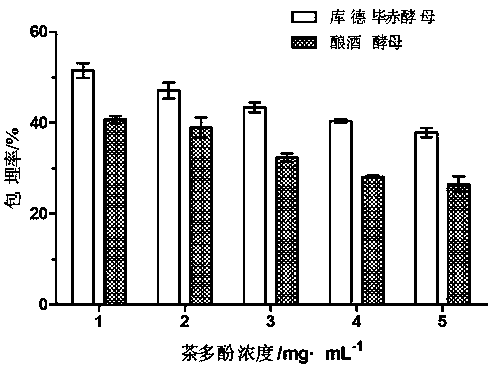

Embodiment 1

[0030] 1) Solid activation of Pichia kurdori and Saccharomyces cerevisiae, that is, respectively inoculated in solid slant medium and cultured in a constant temperature incubator;

[0031] 2) Then perform liquid activation, inoculate the two yeasts activated on the inclined plane into the liquid medium, and culture with shaking; then take a certain volume of liquid-activated yeast suspension and add it to the liquid medium, and shake and expand the culture;

[0032] 3) Centrifuge, flocculate or membrane filter the culture medium obtained in step 2), and obtain two kinds of yeast sludge after washing;

[0033] 4) Add 3wt% NaCl solution to the yeast sludge prepared in step 3) at a ratio of 1:20, adjust to pH 5.5, shake in a water bath at 55°C for 20 hours for plasmolysis; after the end, cool to room temperature, centrifuge, and wash with water 3 times , collecting the precipitate, and freeze-drying to obtain cell wall materials of Pichia kurdori and Saccharomyces cerevisiae for ...

Embodiment 2

[0037] 1) Pichia pichia is firstly activated on a solid, that is, Pichia pichia is inoculated in a solid slant medium and cultured in a constant temperature incubator;

[0038] 2) Then perform liquid activation, inoculate the activated Pichia kurdori on the slant in the liquid medium, and shake and cultivate; then take a certain volume of liquid-activated yeast suspension and add it to the liquid medium, and shake and expand the culture;

[0039] 3) Centrifuge, flocculate or membrane filter the culture medium obtained in step 2), and obtain yeast sludge after washing;

[0040] 4) Add 3wt% NaCl solution to the yeast slime prepared in step 3) at a ratio of 1:20, adjust to pH 5.5, shake in a water bath at 55°C for 20 hours for plasmolysis; after the end, cool to room temperature, centrifuge, and wash with water 3 times. Collect the precipitate and freeze-dry to obtain the yeast cell wall material for subsequent use;

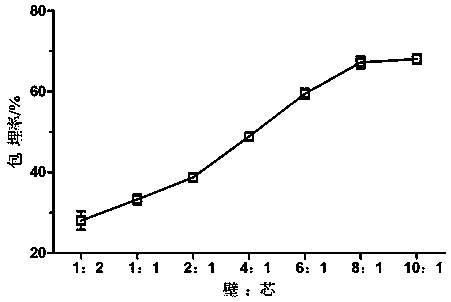

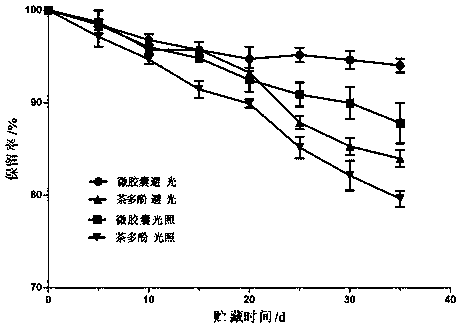

[0041] 5) Mix the wall material and core material (tea polyph...

Embodiment 3

[0044] 1) Pichia pichia is firstly activated on a solid, that is, Pichia pichia is inoculated in a solid slant medium and cultured in a constant temperature incubator;

[0045] 2) Followed by liquid activation, inoculate the activated Pichia kurdori on the slope into the liquid medium, and shake culture; then take a certain volume of liquid-activated bacterial suspension and add it to the liquid medium, and shake and expand the culture;

[0046] 3) Centrifuge, flocculate or membrane filter the culture medium obtained in step 2), and obtain yeast sludge after washing;

[0047] 4) Add 5wt% NaCl solution to the yeast sludge prepared in step 3) at a ratio of 1:20, adjust to pH 5.5, and shake in a water bath at 55°C for 20 hours for plasmolysis; after the end, cool to room temperature, centrifuge, and wash with water 3 times. Collect the precipitate and freeze-dry to obtain the yeast cell wall material for subsequent use;

[0048] 5) Mix the yeast cell wall material prepared in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com