Patents

Literature

64 results about "Pichia kudriavzevii" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

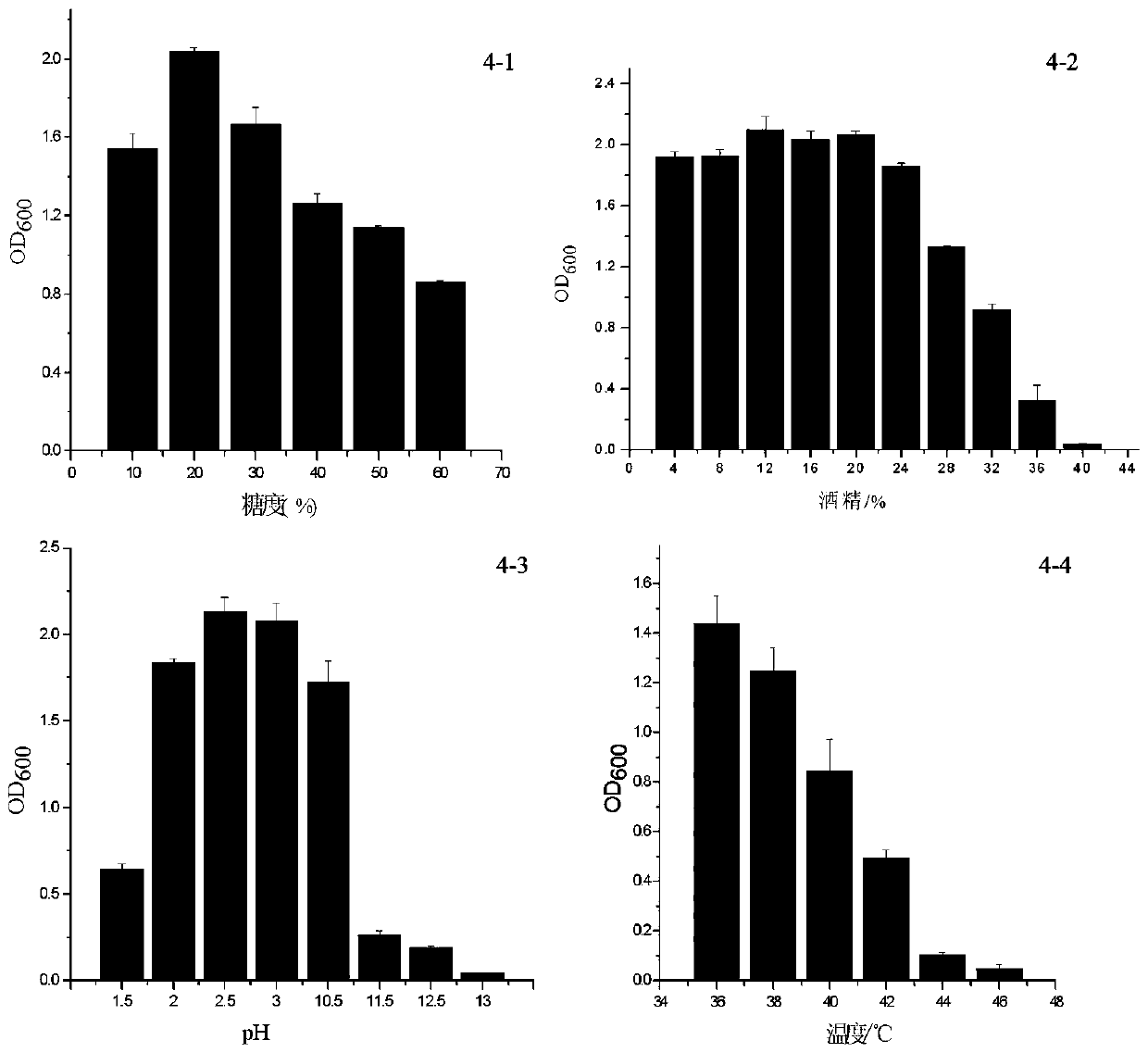

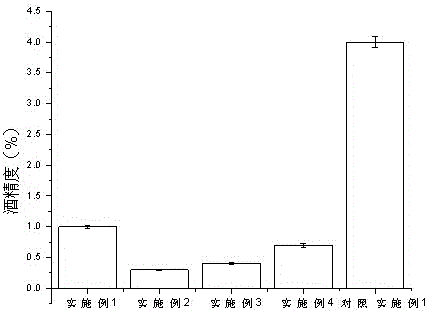

Pichia kudriavzevii strain for preparing beta-phenethyl alcohol through biological transformation of L-phenylalanine, culture method and applications thereof

ActiveCN107629973AIncrease productionImprovement ingredientsFungiMicroorganism based processesMicroorganismNatural product

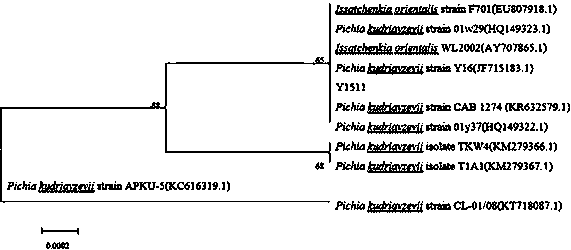

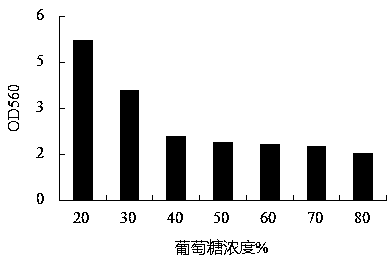

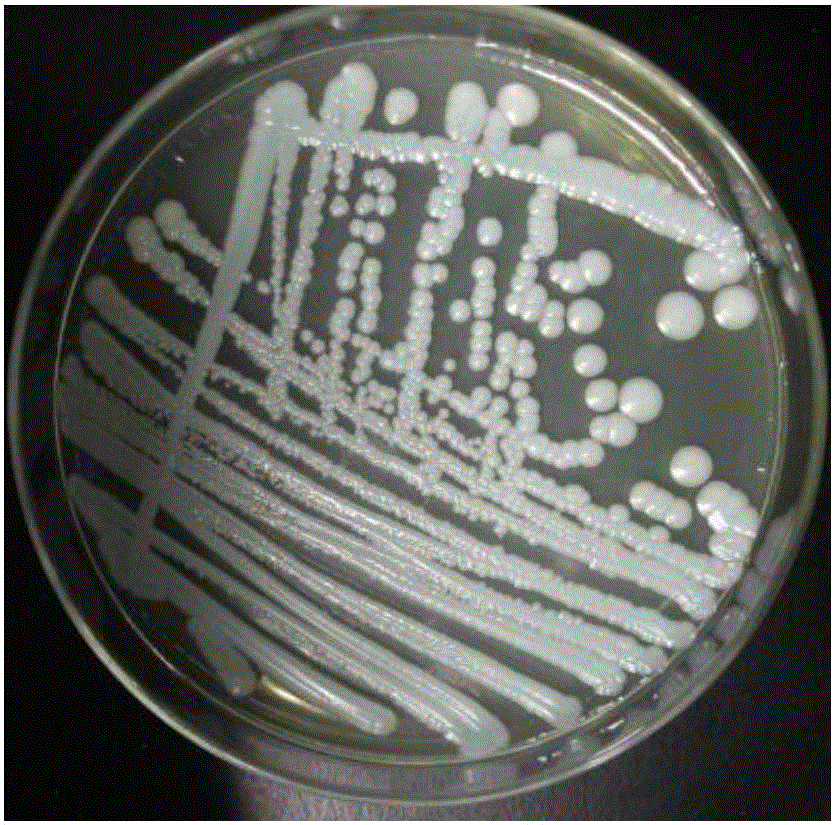

The present invention relates to a Pichia kudriavzevii strain for preparing beta-phenethyl alcohol through biological transformation of L-phenylalanine, a culture method and applications thereof, wherein the Pichia kudriavzevii strain is named Pichia kudriavzevii Y1511, is preserved in the China General Microbiological Culture Collection Center on May 31, 2016, and has the preservation number of CGMCC 12567. According to the present invention, the 26S rDNA D1 / D2 sequence of the strain and the 26S rDNA D1 / D2 sequences of other Pichia kudriavzevii strains have the similarity of 99%; the strain of the present invention has advantages of good sugar tolerance, good ethanol tolerance, good phenethyl alcohol tolerance, wide growth pH valve range and wide temperature range; the screened Pichia kudriavzevii Y1511 of the present invention has the high beta-phenethyl alcohol yield, wherein the detection results show that the beta-phenethyl alcohol yield can achieve 1.0-11.0 g / L, such that the strain can be easily applied in the industrial production of beta-phenethyl alcohol; and the strain of the present invention has advantages of mild reaction conditions, environmentally friendly and natural product, low cost, environmental friendliness and the like.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

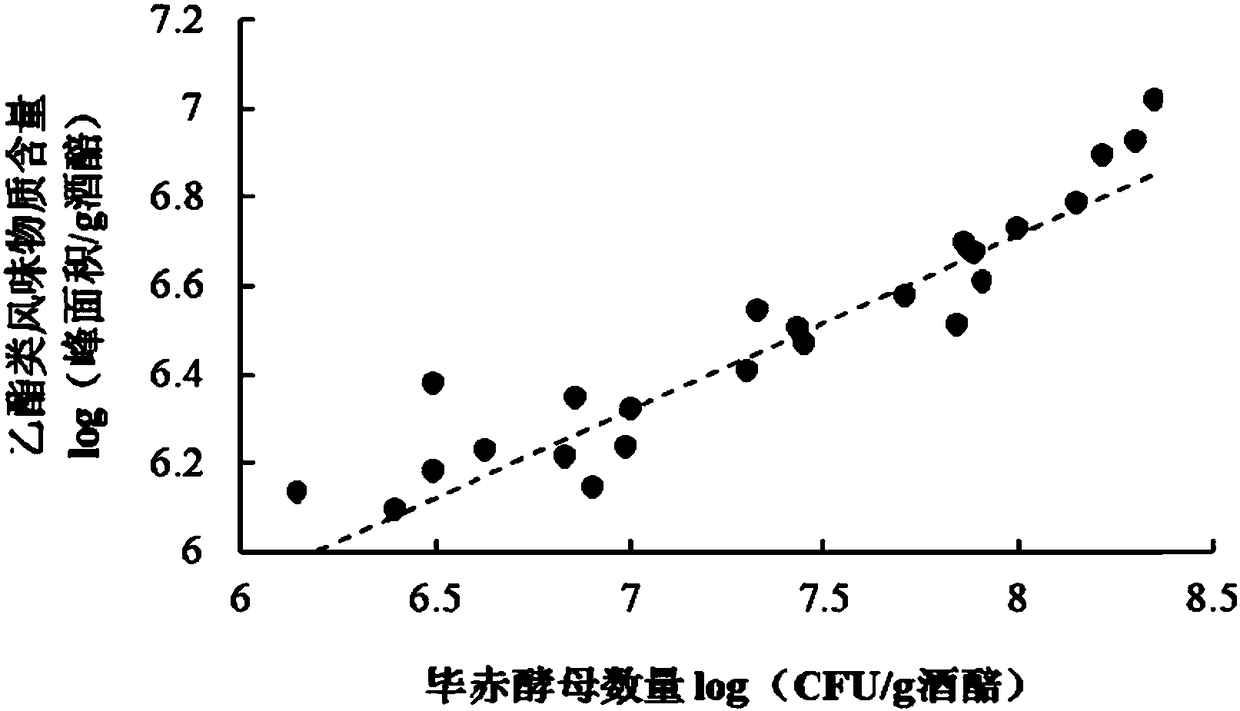

Pichia kudriavzevii yeast low in urea yield and capable of producing flavor and application thereof to food fermentation

ActiveCN105861345AReduce outputReduce formationFungiMicroorganism based processesMicroorganismAlcohol

The invention discloses pichia kudriavzevii yeast low in urea yield and capable of producing flavor and application thereof to food fermentation and belongs to the fields of wine brewing and food safety. The pichia kudriavzevii yeast is separated from a baijiu fermentation environment (yeast for making hard liquor), named as Pichia kudriavzevii JZ523 and preserved in the General Microbiology Centre of Microbial Preservation Management Committee in China on May 6th, 2016 with the preservation number being CGMCC NO.12418. The strain has the advantages of being low in urea yield, capable of producing flavor, resistant to ethyl alcohol and resistant to acid, is an excellent liquor-making functional strain and can be applied to the fields of fermented wine, distilled liquor and other food, and food safety is guaranteed.

Owner:JIANGNAN UNIV

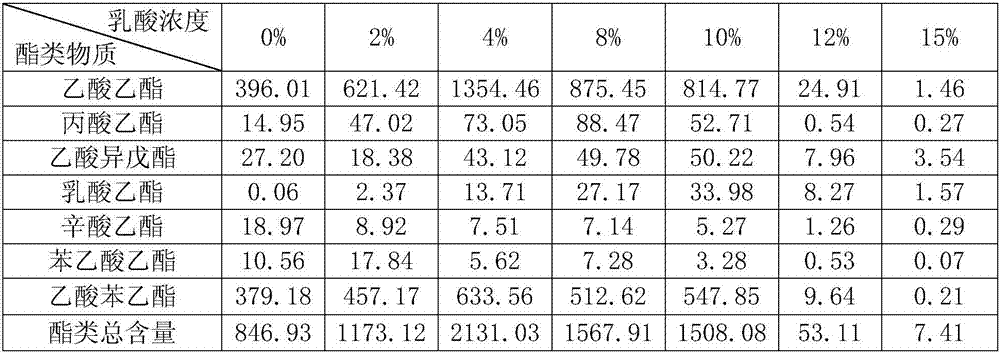

Lactic acid-tolerant ester-producing pichia pastoris

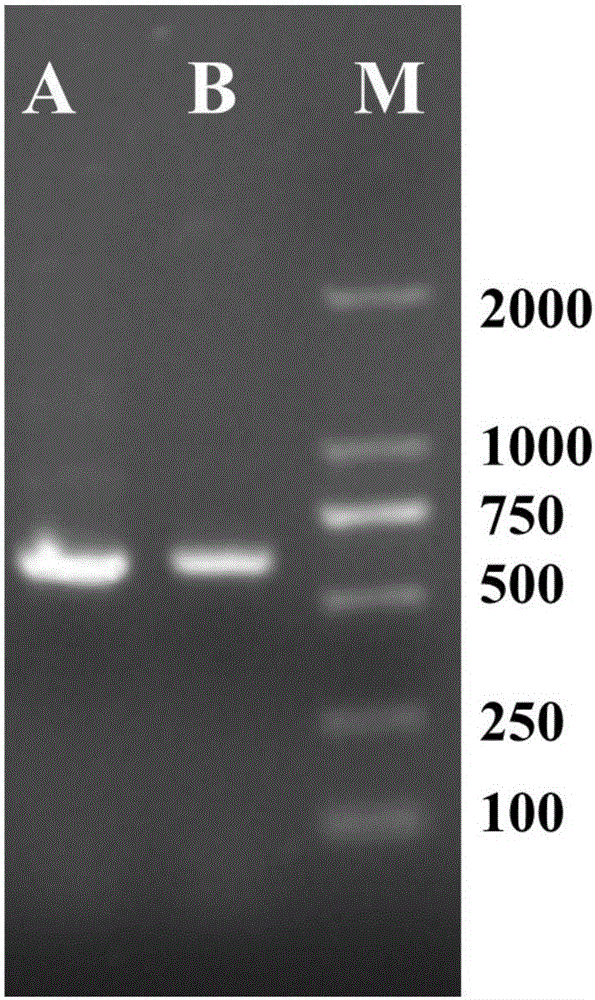

ActiveCN107287127ARapid growthImprove adaptabilityFungiMicroorganism based processesPichia pastorisEthyl phenylacetate

The invention discloses a lactic acid-tolerant ester-producing pichia pastoris, and belongs to the technical field of a bioengineering technology and a brewing biotechnology. The strain is preserved at the General Microbiology Center of the China Committee for Culture Collection of Microorganisms on April 24, 2017, the classification is named pichia kudriavzevii (Pichia kudriavzevii) and the preservation number is CGMCC No.14068. The pichia pastoris is high in environmental tolerance, is capable of tolerating 0-15% lactic acid, is capable of metabolizing to generate multiple ethyl ester volatile flavor substances, such as ethyl acetate, ethyl propionate, ethyl caprylate, phenethyl acetate and ethyl phenylacetate in the environment of 0-12% lactic acid, and is a brewing functional strain with excellent performance.

Owner:KWEICHOW MOUTAI COMPANY

Aroma producing yeast strain and application thereof

ActiveCN110846236APromote aroma productionImprove qualityFungiAlcoholic beverage preparationBiotechnologyMicrobiology

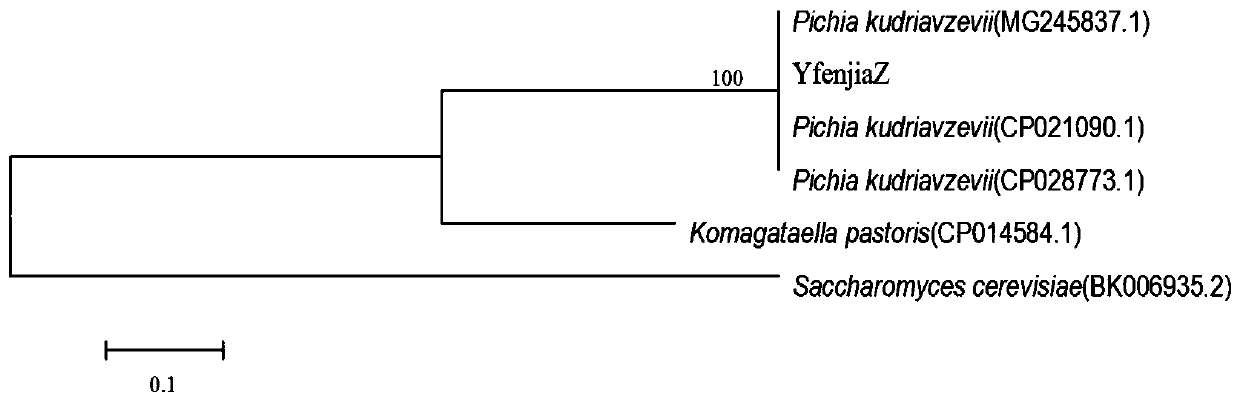

The invention discloses an aroma producing yeast strain and application thereof. The aroma producing yeast strain YfenjiaZ capable of generating strong fruity flavor is separated and screened out fromfen-flavor Baijiu fresh fermented grains through smelling technology, belongs to pichia kudriavzevii and is collected under the number of CGMCC No.16197. The strain has high aroma producing ability in culture media taking cereals as a raw material, and ethyl acetate in main aroma substances accounts for 59.59%. Fen-flavor Baijiu high in ethyl acetate content and ethyl acetate / ethyl lactate ratioand strong in fruity flavor can be produced by utilizing the strain for fermentation and can serve as high-ethyl acetate / ethyl lactate-ratio flavoring liquor or fen-flavor base liquor to be used for blending of Baijiu.

Owner:SHANXI AGRI UNIV

Brewing method of purple sweet potato Huangguan pear composite fruit wine

InactiveCN106967552AClear and transparent colorStable textureAlcoholic beverage preparationMicroorganism based processesPectinaseAlcohol by volume

The invention discloses a brewing method of purple sweet potato Huangguan pear composite fruit wine. The brewing method comprises following steps: material selection and raw material pretreatment; enzymatic saccharification; SO2 sterilization; sugar blending and acid blending; preparation of a saccharomycetes seed solution; inoculation and fermentation; aging and fermentation; bottle changing and clarification; and finished product blending and diatomite filtering. According to the brewing method, purple sweet potato is subjected to enzymatic hydrolysis with amylase, and then is mixed with pear juice; an obtained mixture is subjected to saccharification with pectase and glucoamylase, so that enzymatic hydrolysis juice yield of mashed purple sweet potato is increased to be 68% or higher, and purple sweet potato Huangguan pear juice saccharification juice yield is increased to be 70% or higher via appropriate enzymatic hydrolysis and saccharification; Pichia kudriavzevii fermentation is adopted, and appropriate fermentation technical conditions are adopted, so that the alcohol by volume of the purple sweet potato Huangguan pear composite fruit wine is 12%vol or higher. The color of the purple sweet potato Huangguan pear composite fruit wine is clear; the purple sweet potato Huangguan pear composite fruit wine is transparent, the texture is fine and stable, the purple sweet potato Huangguan pear composite fruit wine possesses the fruit flavor and health care effect of both purple sweet potato and Huangguan pear, the flavor is unique, mellow and full, and fresh, and the purple sweet potato Huangguan pear composite fruit wine is abundant in nutrients.

Owner:XUZHOU UNIV OF TECH

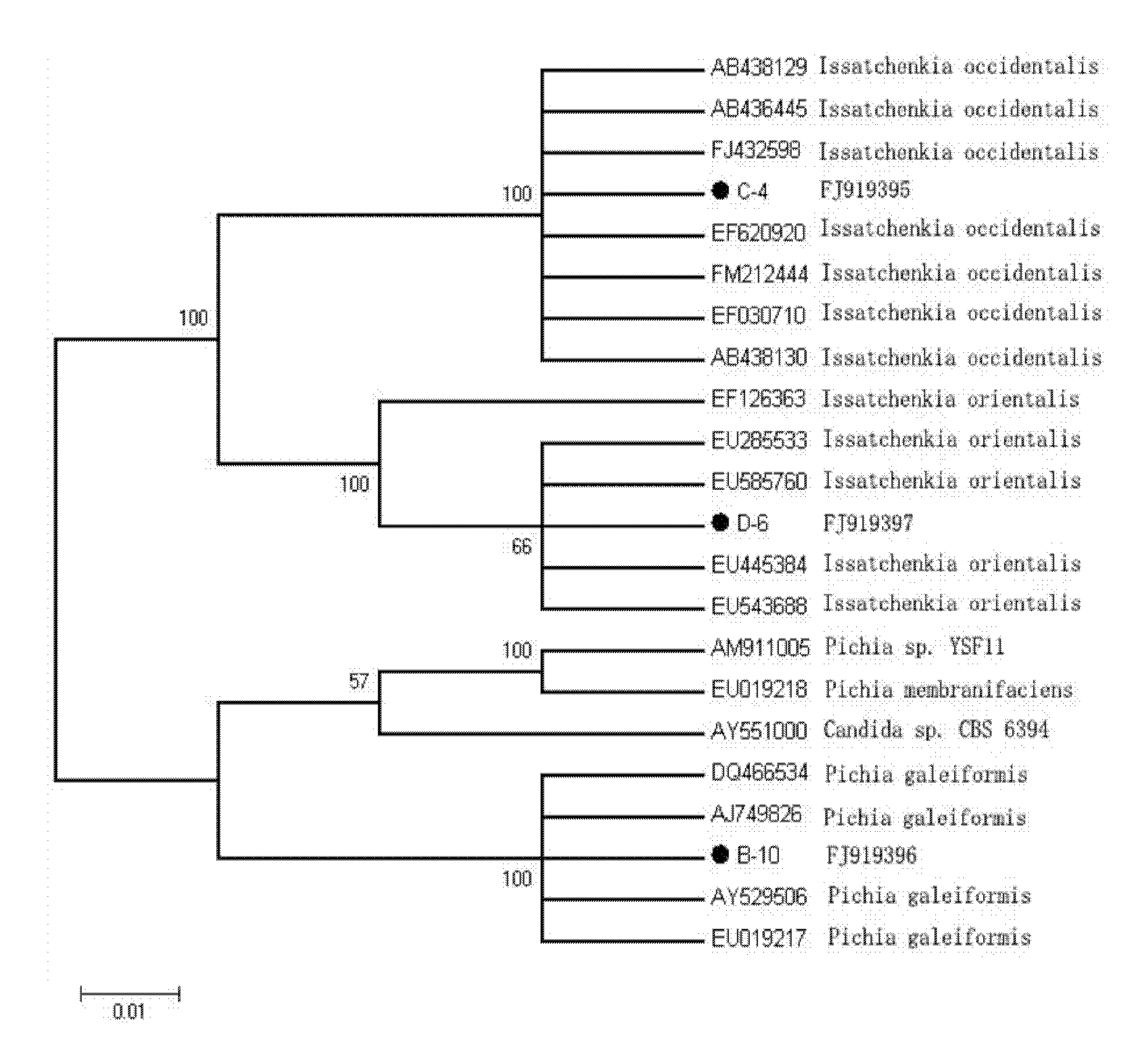

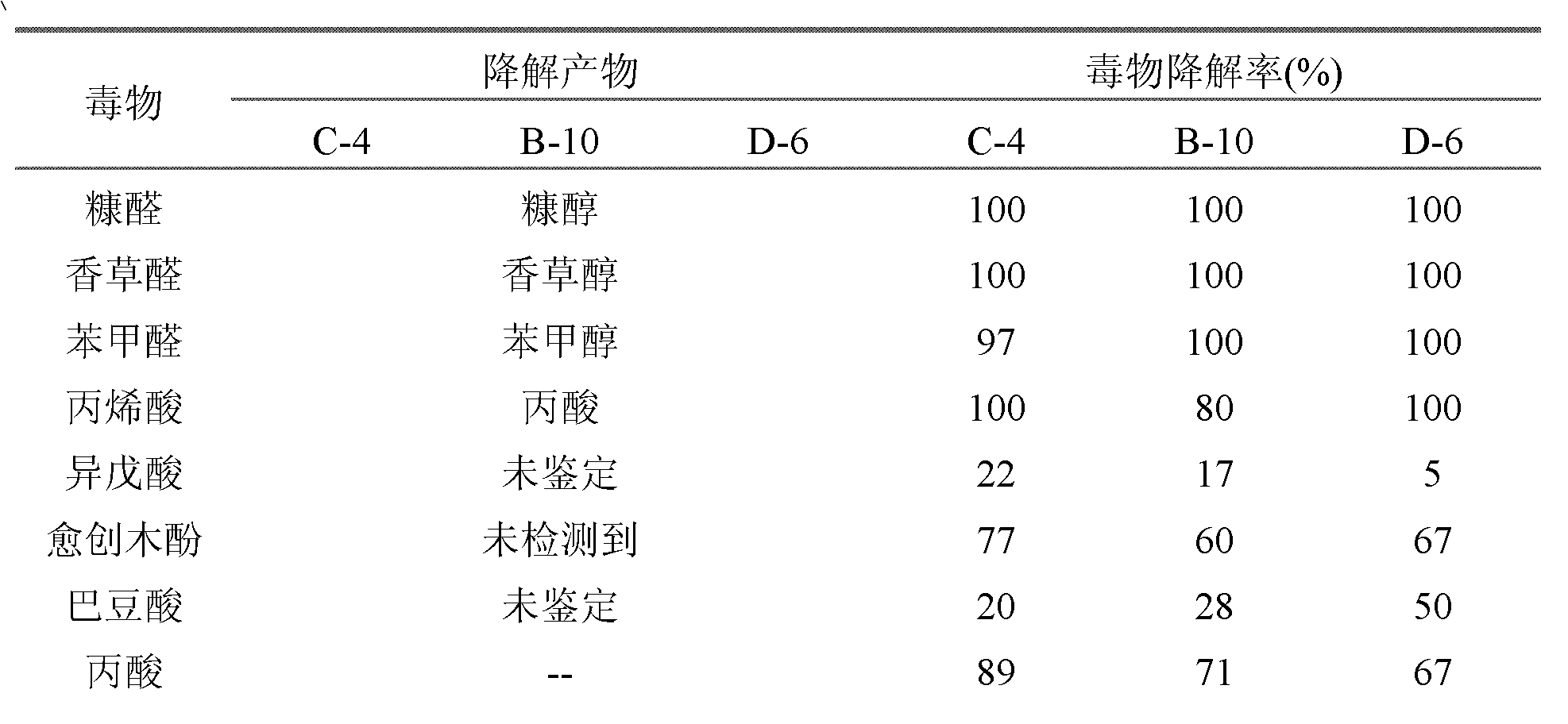

Novel pichia strain and method for mixing and culturing same to biologically detoxify hemicellulose hydrolysate

ActiveCN102010833AToxic ingredients are well toleratedHas a synergistic detoxification effectFungiMicroorganism based processesHydrolysateAlcohol sugars

The invention discloses a novel pichia strain and a method for mixing and culturing the same to biologically detoxify hemicellulose hydrolysate. The novel pichia strain comprises pichia galeiformis CCTCCNO:M 209245 (B-10), pichia occidentalis CCTCC NO:M 209273 (C-4), and pichia kudriavzevii CCTCC NO:M 209274 (D-6) which have degrading activity for 12 known microbial metabolism inhibitors existed in the hemicellulose hydrolysate, has the characteristics of good poison resistance and quick detoxifying process and does not use pentose or pentose alcohol. In the invention, three strains are used for jointly carrying out biological detoxifying fermentation for the hemicellulose hydrolysate, and the xylitol fermentation performance of the treated hydrolysate can reach a fermentation performance achieved by using pure xylose as stroma. The invention has the advantages of environmental protection and cost saving.

Owner:谷创芯生物科技(厦门)有限公司

Composite fermentation group agent and application thereof in brewing cabernet sauvignon straw wine

ActiveCN109097291ARich layersHelps to enhance fragranceFungiMicroorganism based processesFermentation brothBrewing

The invention discloses a composite fermentation group agent and an application thereof in brewing a cabernet sauvignon straw wine. A non-saccharomyces cerevisiae Pichia kudriavzevii F0-N475-5 is obtained by separating, sampling, cultivating and screening from a wine early fermentation liquor from a brewing location in Shihezi area in Xinjiang; the prepared non-saccharomyces cerevisiae F0-N475-5 secondary fermentation liquor and the S.cerevisiae GTGM-E2 secondary fermentation liquor are mixed in the ratio of 1:1. The prepared composite fermentation group agent is applied to fermentation of thesouth Xinjiang cabernet sauvignon straw wine with complex taste, prominent layering, rich and complex fragrance, elegant and delicate taste, long aftertaste, harmonious aroma and taste, excellent overall quality and outstanding style. The single style of relying on active dry yeast fermentation of the wine is broken through, and remarkable good technical effects are achieved.

Owner:TARIM UNIV

Novel compound microbial agent and preparation method thereof

InactiveCN106967643AGood deodorizing effectHas the effect of killing fliesFungiBacteriaBiotechnologyMicrobial agent

The invention discloses a novel compound microbial agent. The novel compound microbial agent is prepared from an active seed fluid and a producing culture medium by volume ratio of 2 to 10. The active seed fluid is prepared from bacillus velezensis, camellia flower lactobacillus, Pichia kudriavzevii, brewer's yeast, acetobacter pasteurianus, lactobacillus plantarum and lactobacillus casei by volume ratio of (10-20) to (3-9) to (2-4) to (1-5) to (1-5) to (1-3) to (1-3). The producing culture medium is prepared from 200-300 kg of tomatoes, 200-300 kg of bean sprouts, 100-200 kg of wheat bran, 300-400 kg of brown sugar, 250-350 kg of molasses, 2-6 kg of peptone, 2-7 kg of yeast extract and 3-9 kg of glacial acetic acid which are contained in every 10 tons of water. The production and fermentation process is simple, the deodorization efficiency is high, microbial flora are stable, and he applicability is high.

Owner:HUNAN PUTAIER ENVIRONMENTAL CO LTD

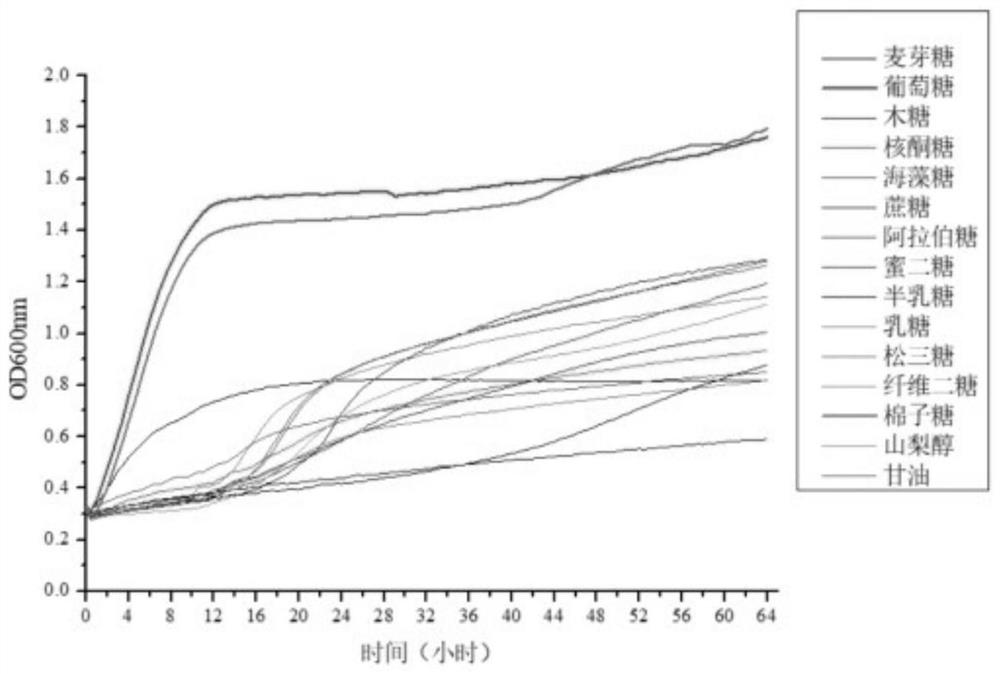

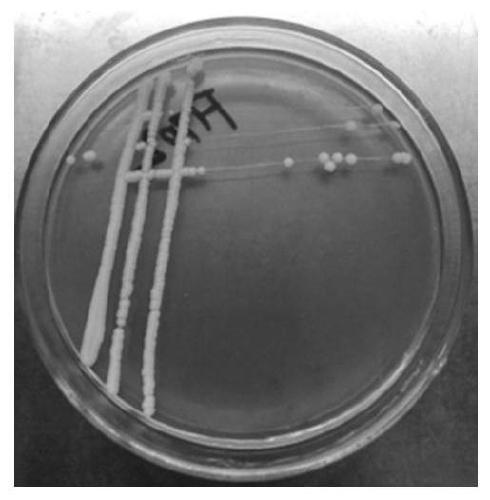

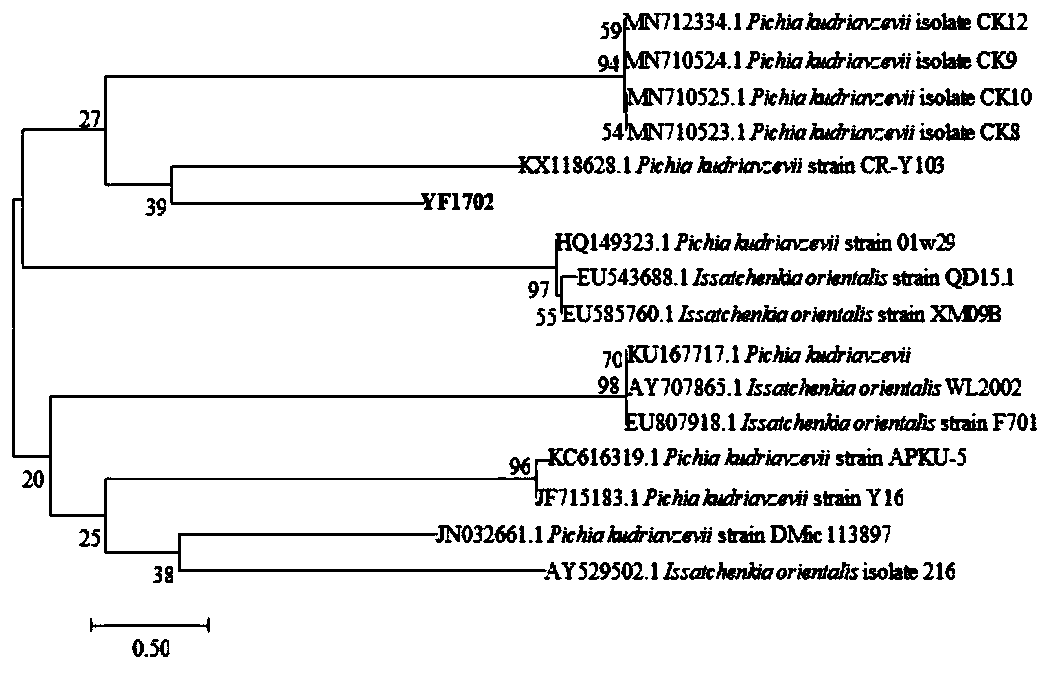

Aroma-producing pichia kudriavzevii for degrading ammonia nitrogen and application of aroma-producing pichia kudriavzevii

ActiveCN111996131AStrong toleranceStable strainFungiWater contaminantsMicroorganismAmmoniacal nitrogen

The invention belongs to the technical field of industrial microorganisms, and relates to aroma-producing pichia kudriavzevii for degrading ammonia nitrogen and application of the aroma-producing pichia kudriavzevii. The aroma-producing pichia kudriavzevii capable of degrading ammonia nitrogen is classified and named as pichia kudriavzevii HJ2, and is preserved in the China General MicrobiologicalCulture Collection Center on June 01, 2020, with the preservation number of CGMCC NO.19897. The pichia kudriavzevii provided by the invention can generate rich aromatic compounds by independently utilizing organic matters of pentose and hexose, is resistant to salt and heavy metal, can adapt to a wide pH range, and enlarges environmental conditions for treating wastewater containing ammonia nitrogen. The strain can be used for treating a water body containing high-concentration ammonia nitrogen, and the production process is friendly to environment, simple to operate, free of secondary pollution, and particularly suitable for industrial large-scale production.

Owner:GUANGXI UNIV

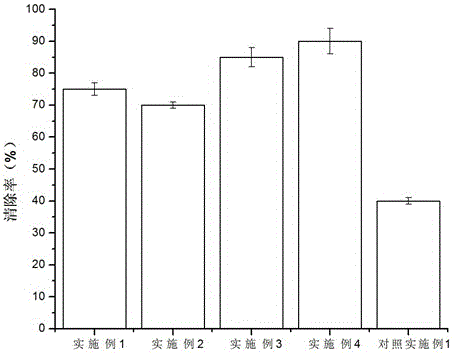

Apple enzyme and preparation method thereof

ActiveCN106722943ARetain activityReduce lossesCosmetic preparationsYeast food ingredientsAlcohol contentCarboxymethyl cellulose

The invention discloses an apple enzyme. A preparation method of the apple enzyme comprises the following steps: by taking apples as a main raw material, juicing the apples, filtering apple juice, uniformly mixing the apple juice with pure water, further adding glucose which accounts for 3% of the total weight of the obtained raw material mixture into the raw material mixture, adjusting the pH value to 6.0-7.0, sterilizing, inoculating Pichia kudriavzevii PKD3001 into the obtained fermentation raw material liquid, controlling the rotation speed to 120 r / min, fermenting for 24-72 hours at 25-35 DEG C, sequentially adding 40-80 g of cane sugar, 5-10 g of citric acid and 2-4 g of carboxymethyl cellulose sodium into the obtained fermentation solution by each liter of the fermentation solution, uniformly mixing, sterilizing for 20 min at 121 DEG C, and filling into a can, thereby obtaining a finished product of the apple enzyme. The antioxidant activity of the finished product of the apple enzyme disclosed by the invention is improved by 75% and the alcohol content is less than 1% as compared with those of an apple enzyme obtained by using a natural fermentation method.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

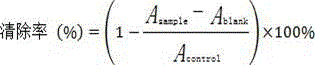

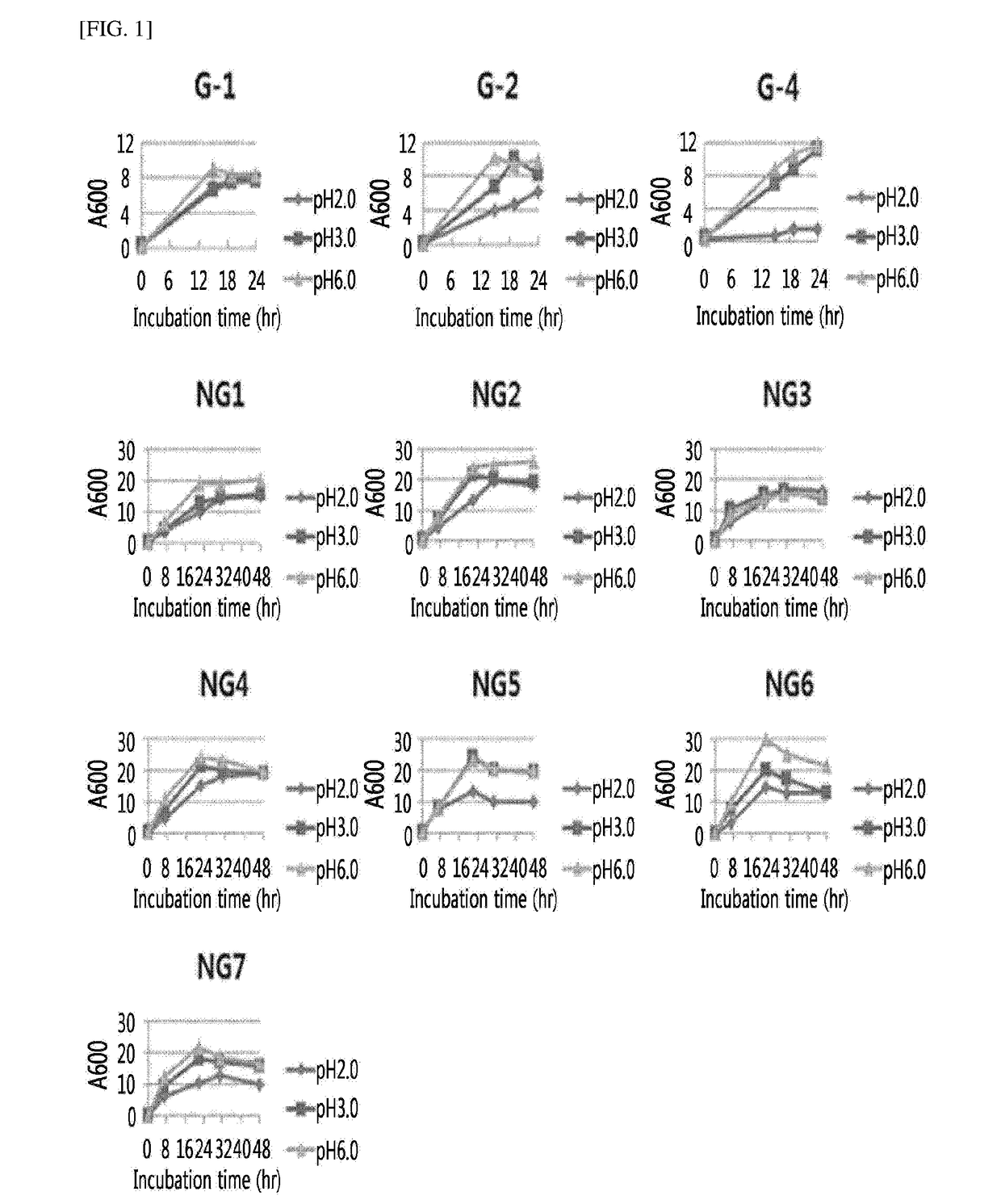

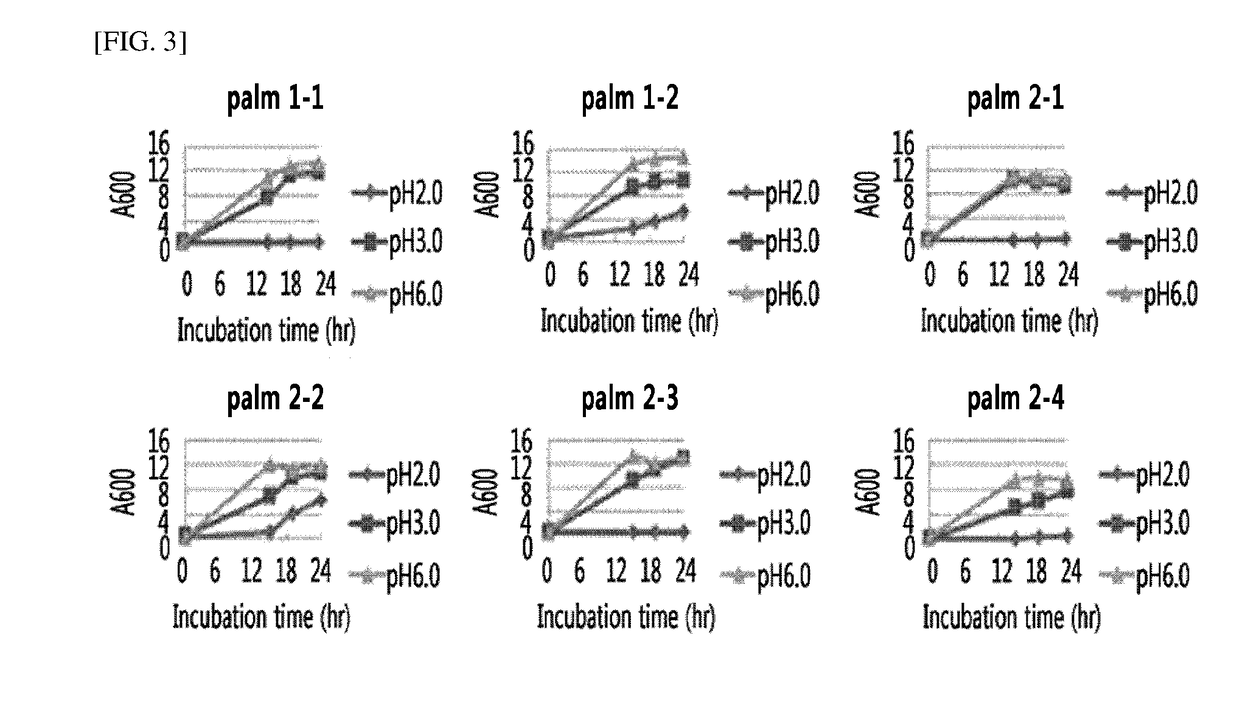

Novel pichia kudriavzevii ng7 microorganism and uses thereof

ActiveUS20170349920A1Improve acid resistanceImprove heat resistanceFungiBiofuelsMicroorganismBiotechnology

The present invention relates to: a novel Pichia kudriavzevii microorganism NG7 showing heat resistance and acid resistance; a composition, for producing organic acid or alcohol, which comprises the microorganism and a culture of the same; and a method, for producing an organic acid or alcohol, which comprises culturing the microorganism.

Owner:KOREA RES INST OF BIOSCI & BIOTECH

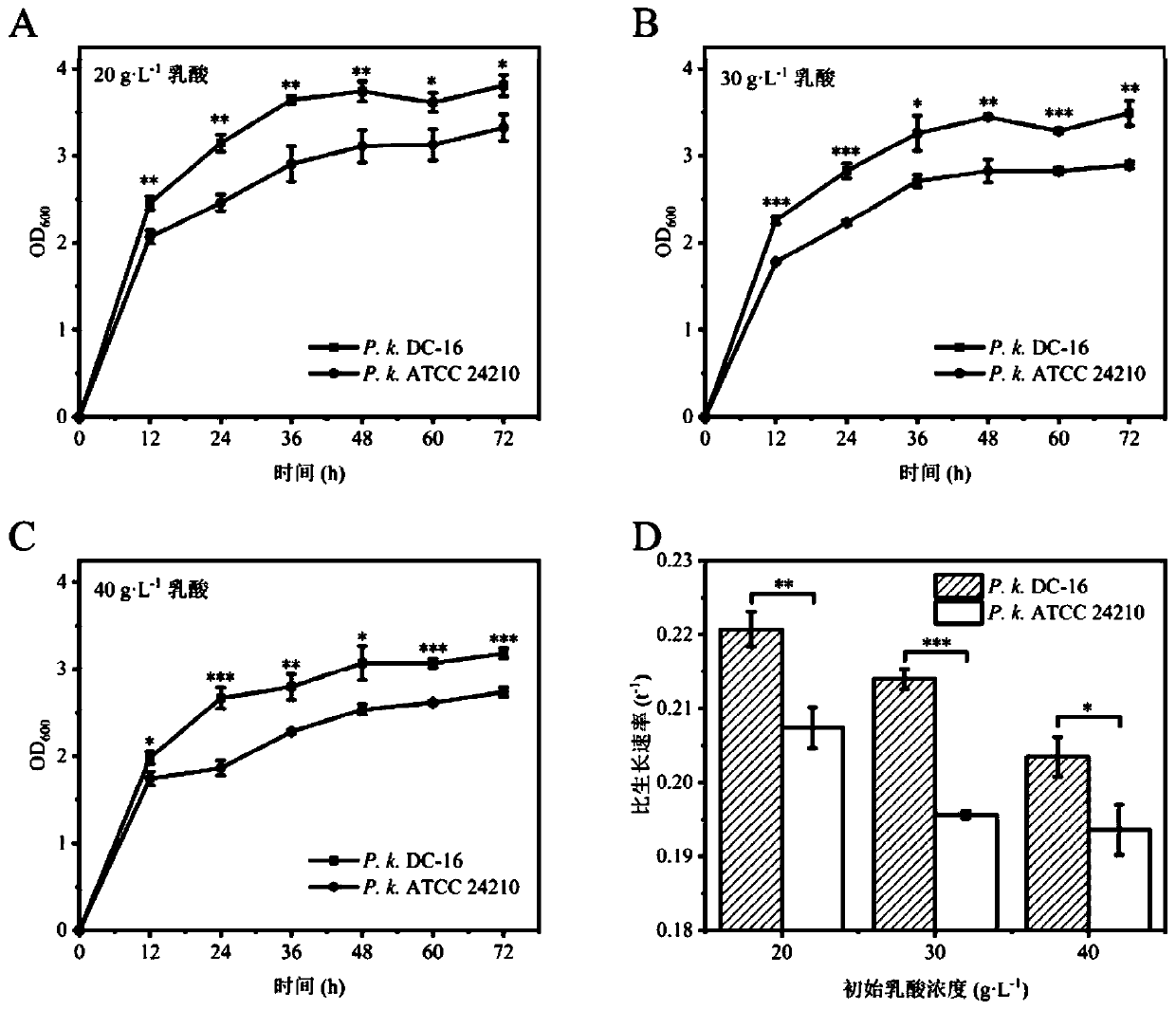

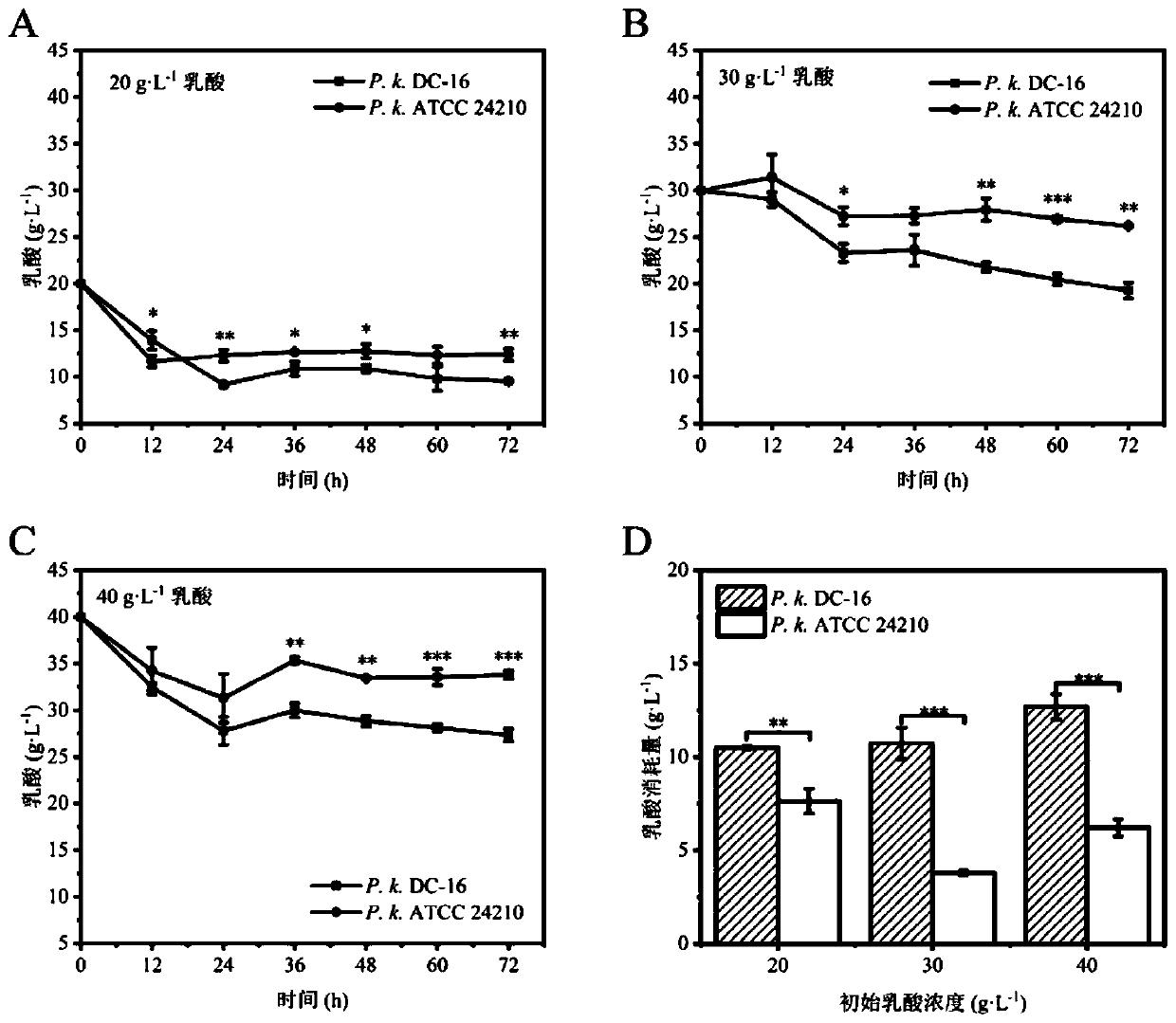

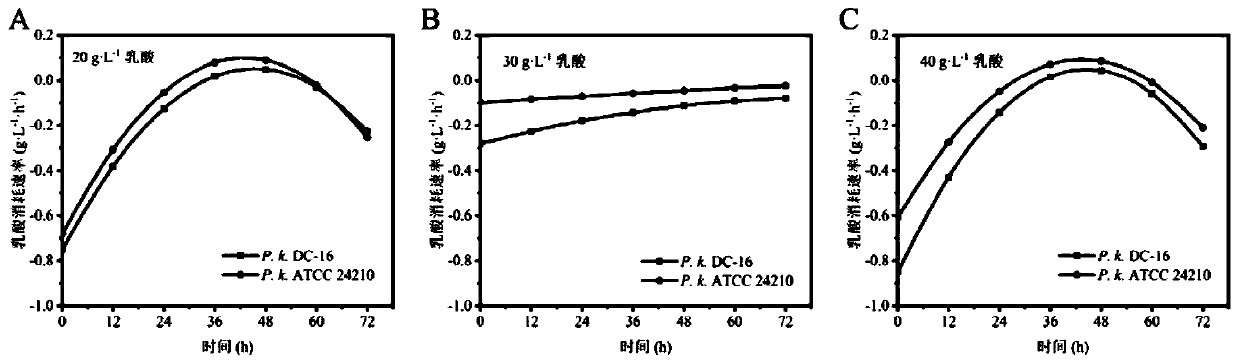

Microbial complex microbial agent for degrading lactic acid

ActiveCN111254085APromote degradationRelieve Lactic Acid StressBiocideFungiBiotechnologyMicrobial agent

The invention discloses a microbial complex microbial agent for degrading lactic acid, and belongs to the technical field of microbes. The degradability of the pichia kudriavzevii provided by the invention to the lactic acid is up to 12.69 g / L, and is 2.04 times that of a model strain; at the same time, the strain can metabolize ethanol, and the OD600 can reach 4.48 after the strain is fermented in a sorghum juice culture medium at 30 DEG C and 200 rpm for 3 days; after fermentation is performed for 60 h, 58 g / L glucose in the sorghum juice culture medium can be completely depleted, and 13.06g / L ethanol can be produced; and the pichia kudriavzevii can relieve lactic acid pressure in a fermentation system when degrading the lactic acid, so that saccharomyces cerevisiae can grow and be metabolized to produce liquor.

Owner:JIANGNAN UNIV

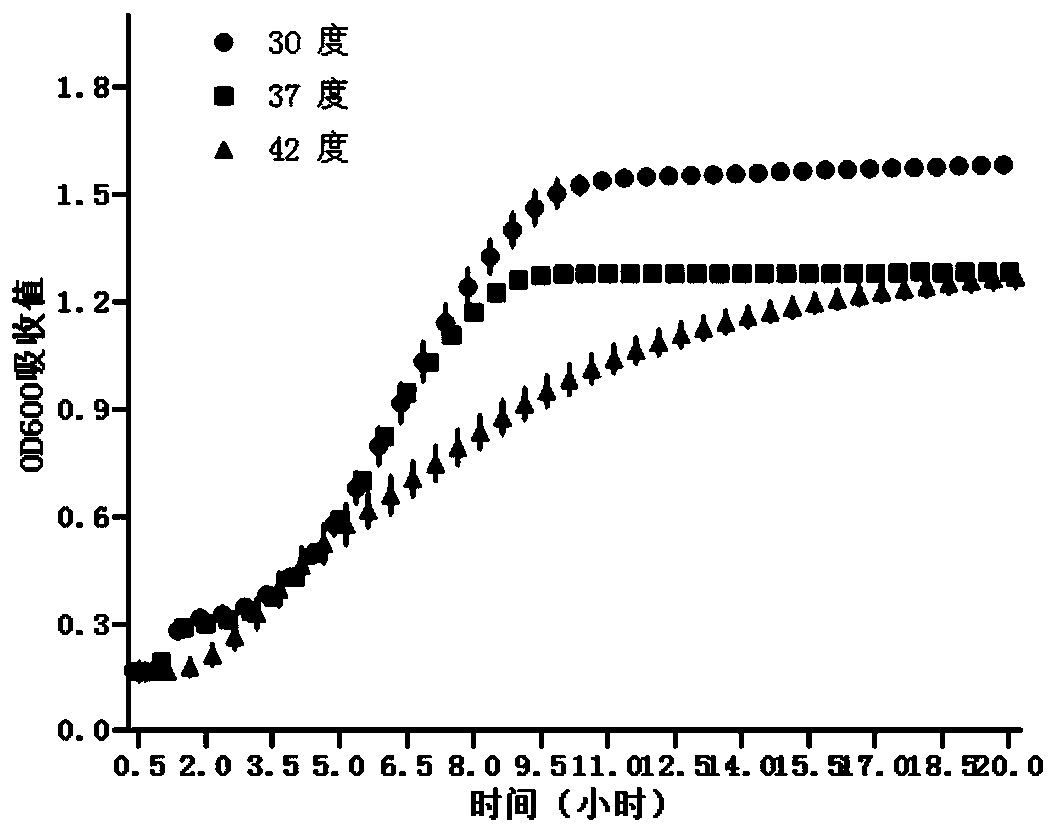

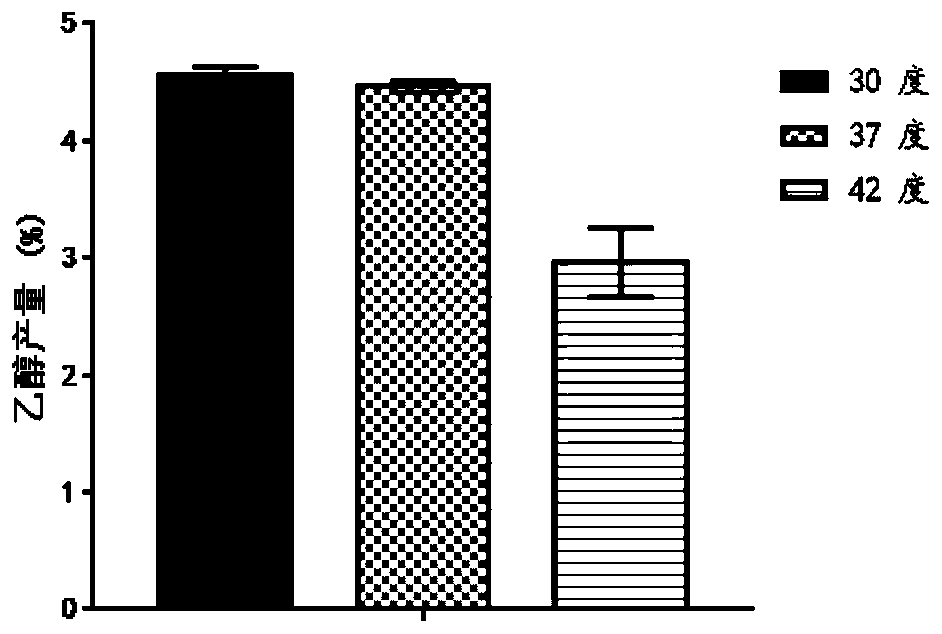

Method for improving high-temperature tolerance of pichia kudriavzevii

ActiveCN105754925AImprove high temperature resistanceHigh temperature resistanceFungiMicroorganism based processesBiotechnologyPichia cactophila

The invention discloses a method for improving the high-temperature tolerance of pichia kudriavzevii.The method includes steps of (1), activating the pichia kudriavzevii, inoculating the activated pichia kudriavzevii in liquid cultivation media and cultivating the pichia kudriavzevii in the cultivation media; (2), carrying out stress treatment on the pichia kudriavzevii, to be more specific, inoculating the activated pichia kudriavzevii into liquid cultivation media with 0.1-20% of substances A and carrying out stress cultivation on the pichia kudriavzevii; (3), collecting high-temperature-tolerant pichia kudriavzevii, to be more specific, centrifugally collecting thalli from the pichia kudriavzevii after stress treatment on the pichia kudriavzevii is carried out and acquiring the high-temperature-tolerant pichia kudriavzevii.The substances A are salts.The method has the advantages that the high-temperature tolerance of the pichia kudriavzevii can be greatly improved, the method is favorable for solving the problem of high energy consumption due to normal-temperature fermentation of pichia kudriavzevii, the fermentation cost can be reduced, and important effects of promoting industrial application of the pichia kudriavzevii can be realized.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

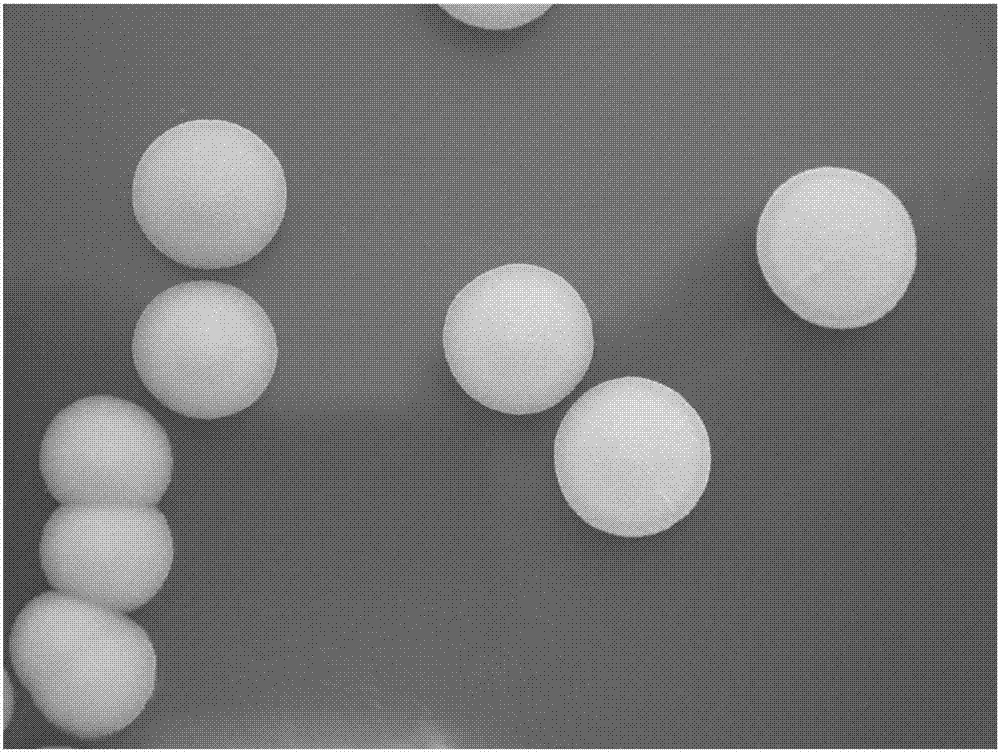

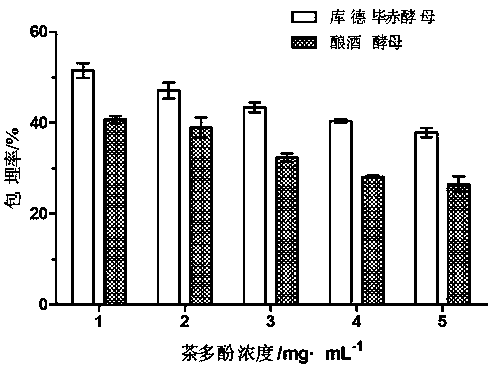

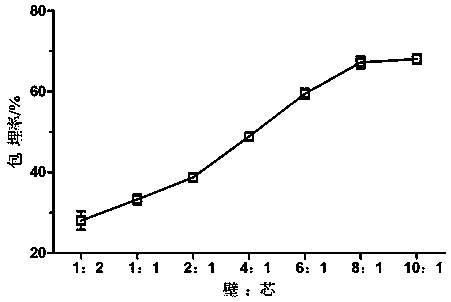

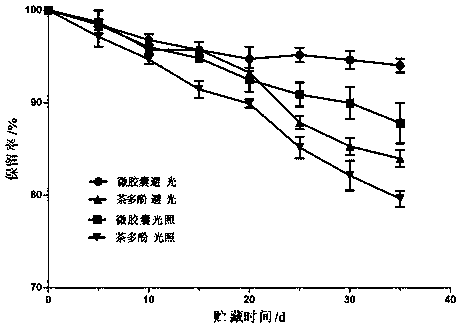

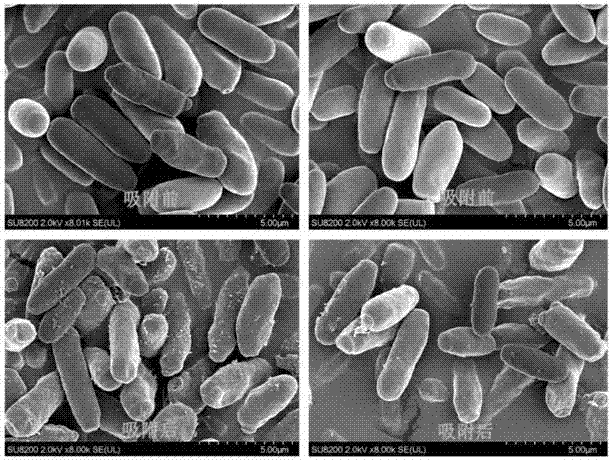

Pichia kudriavzevii embedded tea polyphenol microcapsules and preparation method thereof

InactiveCN109674034AGuaranteed AntioxidantImprove stabilityFood ingredientsFood shapingEmbedding rateHeat resistance

The invention provides pichia kudriavzevii embedded tea polyphenol microcapsules. The microcapsules are characterized in that tea polyphenol yeast microcapsules are specifically prepared through embedding tea polyphenols into yeast cells by utilizing adsorption and assimilation functions of the pichia kudriavzevii. A method is simple in operation steps and low in cost; the embedding rate reaches 68.75 percent and is much higher than that of microcapsule products in the prior art. The tea polyphenol yeast microcapsules prepared by the method also can keep the anti-oxidization performance of theoriginal tea polyphenols; meanwhile, the pichia kudriavzevii has heat resistance and acid and alkali resistance; the tea polyphenol microcapsules can be used for effectively improving the stability of the tea polyphenols under the conditions of illumination and the like.

Owner:OCEAN UNIV OF CHINA

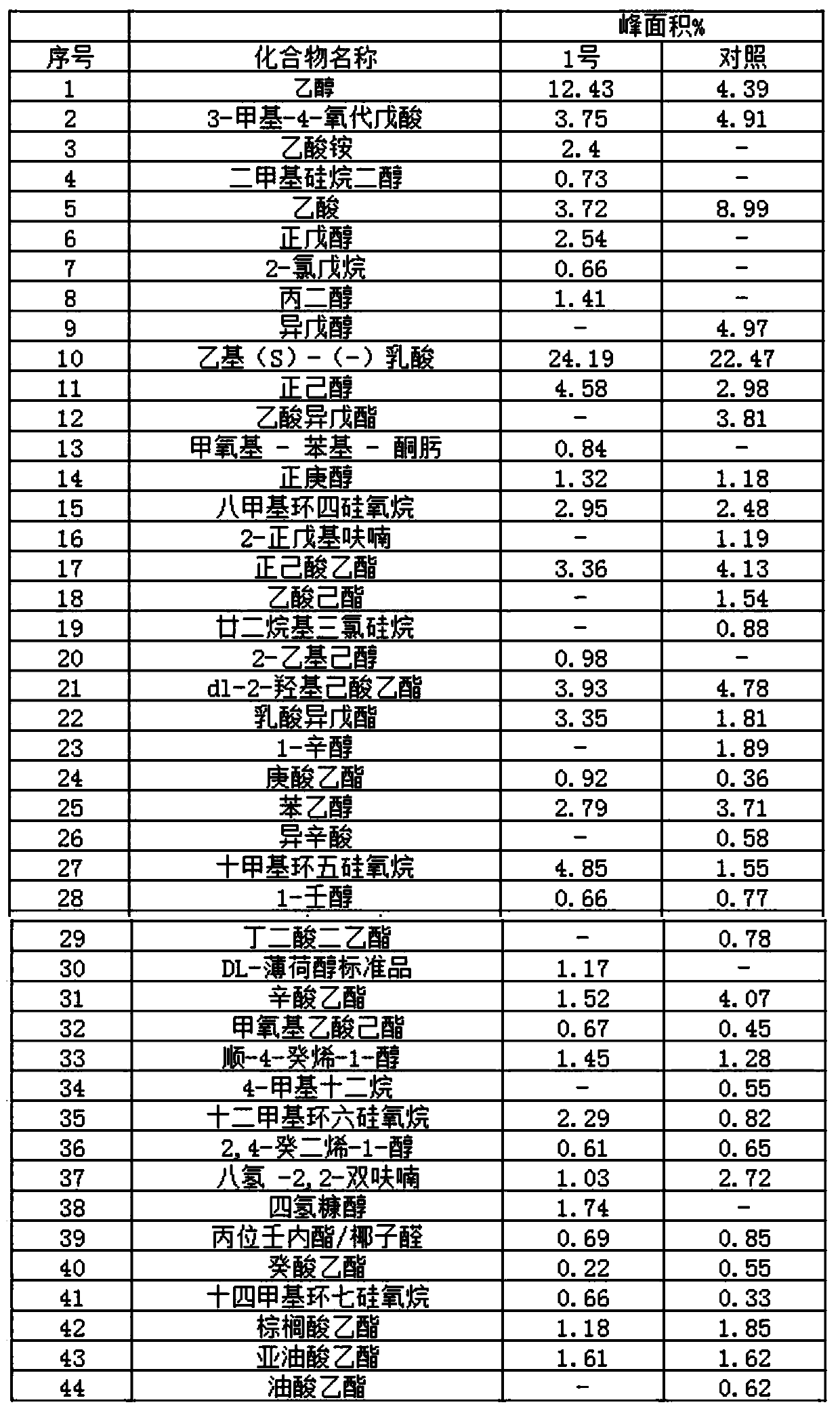

Method for producing flavor blending liquid from pichia kudriavzevii

ActiveCN105199928AEasy to operateClear workmanshipMicroorganism based processesAlcoholic beverage preparationBiotechnologyHypha

The invention discloses a method for producing flavor blending liquid from pichia kudriavzevii. The method includes steps of carrying out slant cultivation, to be more specific, inoculating FBKL2.0008 bacteria of the pichia kudriavzevii on slant cultivation media, and cultivating the FBKL2.0008 bacteria at the temperature of 28 DEG C for 24-48 h until hyphae fully grow on test tubes; activating the bacteria; preparing seed liquid; carrying out solid fermentation by the aid of triangular flasks to obtain fermentation products; preparing the flavor blending liquid, to be more specific, continuously uniformly stirring 26.47% salt solution and 10% ethanol solution in the fermentation products according to a ratio of 1g:1ml:1ml for the stirring time of 5-10 min to obtain mixed liquid and carrying out water bath on the mixed liquid in water bath kettles at the temperatures of 50 DEG C for 30 min; distilling the mixed liquid under the normal pressure at the controlled temperature of 100 DEG C, starting to count the distillation time of 20-40 min when distillates are distilled, collecting 25-75 ml of the distillates in each volumetric flask and refrigerating and storing the volumetric flasks in refrigerators at the temperatures of 4 DEG C. The method has the advantages of short production cycle, high quality product rate and low production cost.

Owner:GUIZHOU UNIV

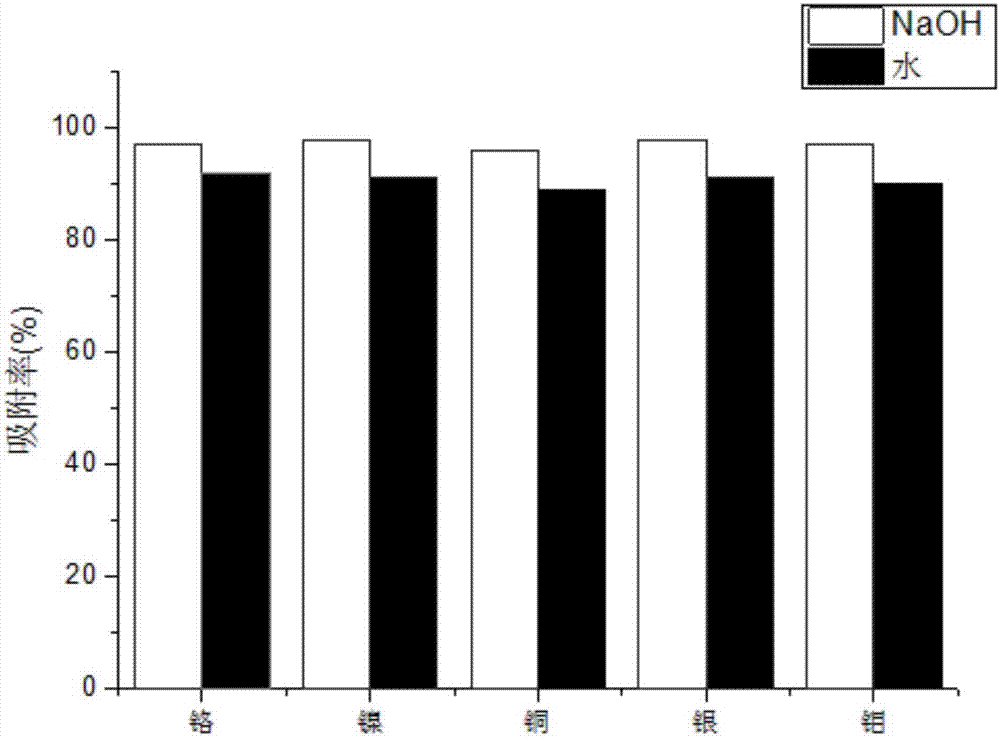

Biological adsorption recycling method for heavy metal in industrial wastewater

InactiveCN107879485AEfficient removalLow costFungiWater contaminantsHigh concentrationResource utilization

The invention discloses a biological adsorption recycling method for heavy metal in industrial wastewater, which is used for treating the industrial wastewater with the chromium, nickel, copper, silver and molybdenum content of 2 mg / L or less and the pH (Potential of Hydrogen) of less than 2. The specific method comprises the following steps: under the condition that the pH is less than 2, feedingin batches and culturing to obtain a high-concentration pichia kudriavzevii bacterium solution; after pre-treating the bacterium solution with NaOH, drying. A dried biological adsorbent is used for treating the industrial wastewater and removing heavy metal ions; the biological adsorbent adsorbed with the heavy metal ions can be separated again and heavy metal is recycled, and resource utilization is carried out. The method disclosed by the invention has the advantages of low product cost, simple technology, no secondary pollution, good adsorption performance and stable performance and is suitable for high-acidity industrial wastewater containing various heavy metal and the like.

Owner:合肥郑国生物科技有限公司 +1

Pichia kudriavzevii resistant to high temperature and stress and high in ethanol yield and application thereof

The invention belongs to the field of biochemical engineering, and particularly relates to pichia kudriavzevii resistant to high temperature and stress and high in ethanol yield and application thereof in bioethanol production. Pichia kudriavzevii is collected under the number of CGMCC NO.18379. The strain has high-temperature resistance and can resist various fermentation inhibitors and stress agents such as 30mM furfural, 70mM acetic acid, 30mM formic acid, 30mM H2O2 and ethanol of 15%, thereby being an advantageous starting strain in industrial production of bioethanol.

Owner:GUANGXI ACAD OF SCI

Combined strain for preparing Mahua fermented leavening dough, Mahua fermented leavening dough, Mahua and application of leavening dough

ActiveCN110241038AAdd flavorThe production process is simple and easy to controlFungiBacteriaFlavorAlcohol

The invention relates to a combined strain for preparing Mahua fermented leavening dough, the Mahua fermented leavening dough, Mahua and application of the leavening dough. The leavening dough is produced by the following steps: subjecting lactobacillus helveticus MRS1, lactobacillus rhamnosus PCA2 and pichia kudriavzevii PDA1 to slant activation, respectively performing pure strain culturing, inoculating flour with the three bacterial solutions after the culture is finished, adding water, performing fermentation for 36-60 hours at a temperature of 25-37 DEG C, and performing fermentation to prepare the leavening dough so as to obtain the fermented leavening dough. The leavening dough is fermented by using the lactobacillus helveticus MRS1, the lactobacillus rhamnosus PCA2 and the pichia kudriavzevii PDA1. Different from the opening and natural fermentation process of traditional leavening dough, the production process is easier to control and can realize industrial production, and the leavening dough can produce abundant flavor substances such as alcohol, aldehyde, acid, ester and the like or flavor precursor substances, and improves the flavor of Mahua.

Owner:桂发祥十八街麻花食品(天津)有限公司

Ester-producing yeast strain and application thereof

PendingCN114107077AMulti-environmental toleranceBroad-spectrum substrate applicabilityFungiMicroorganism based processesPichia stipitisMicrobiology

The invention provides an ester-producing yeast strain and application thereof. The invention provides a pichia kudriavzevii strain, the pichia kudriavzevii strain is a pichia kudriavzevii strain C4.12, the pichia kudriavzevii strain C4.12 is preserved in the China Center for Type Culture Collection (CCTCC), and the preservation number of the pichia kudriavzevii strain C4.12 is CCTCC NO: M 2021124. The pichia kudriavzevii strain is a pichia kudriavzevii strain, and the pichia kudriavzevii strain is a pichia kudriavzevii strain. The yeast strain provided by the invention has the characteristics of multi-environment tolerance, broad-spectrum substrate applicability and ester production, and can improve the sensory flavor of a traditional brewed product, improve the product quality and enrich the product taste.

Owner:ANGELYEAST CO LTD

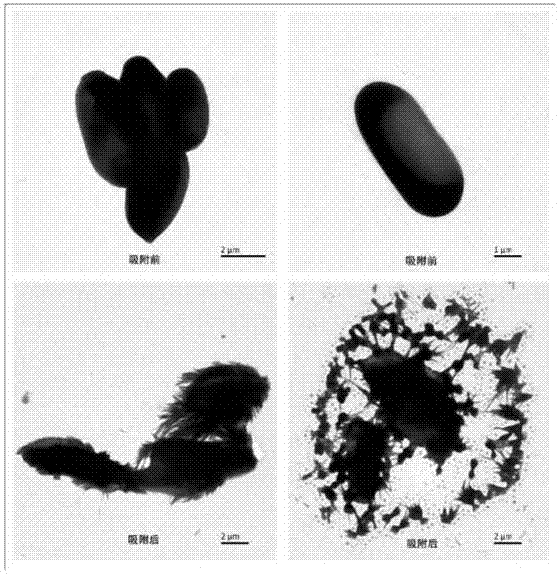

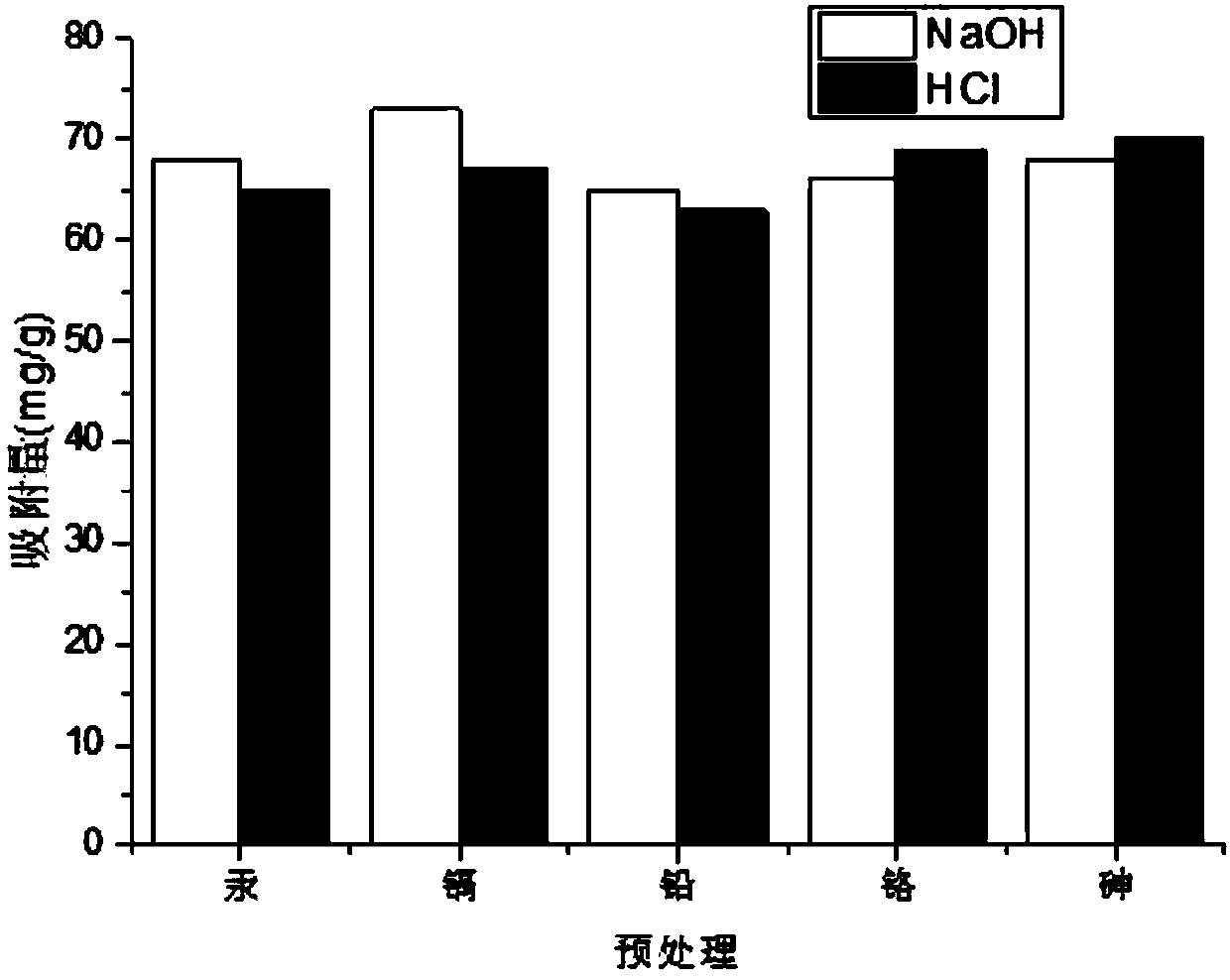

Preparation method and use method of pichia kudriavzevii adsorbent capable of quickly adsorbing heavy metal

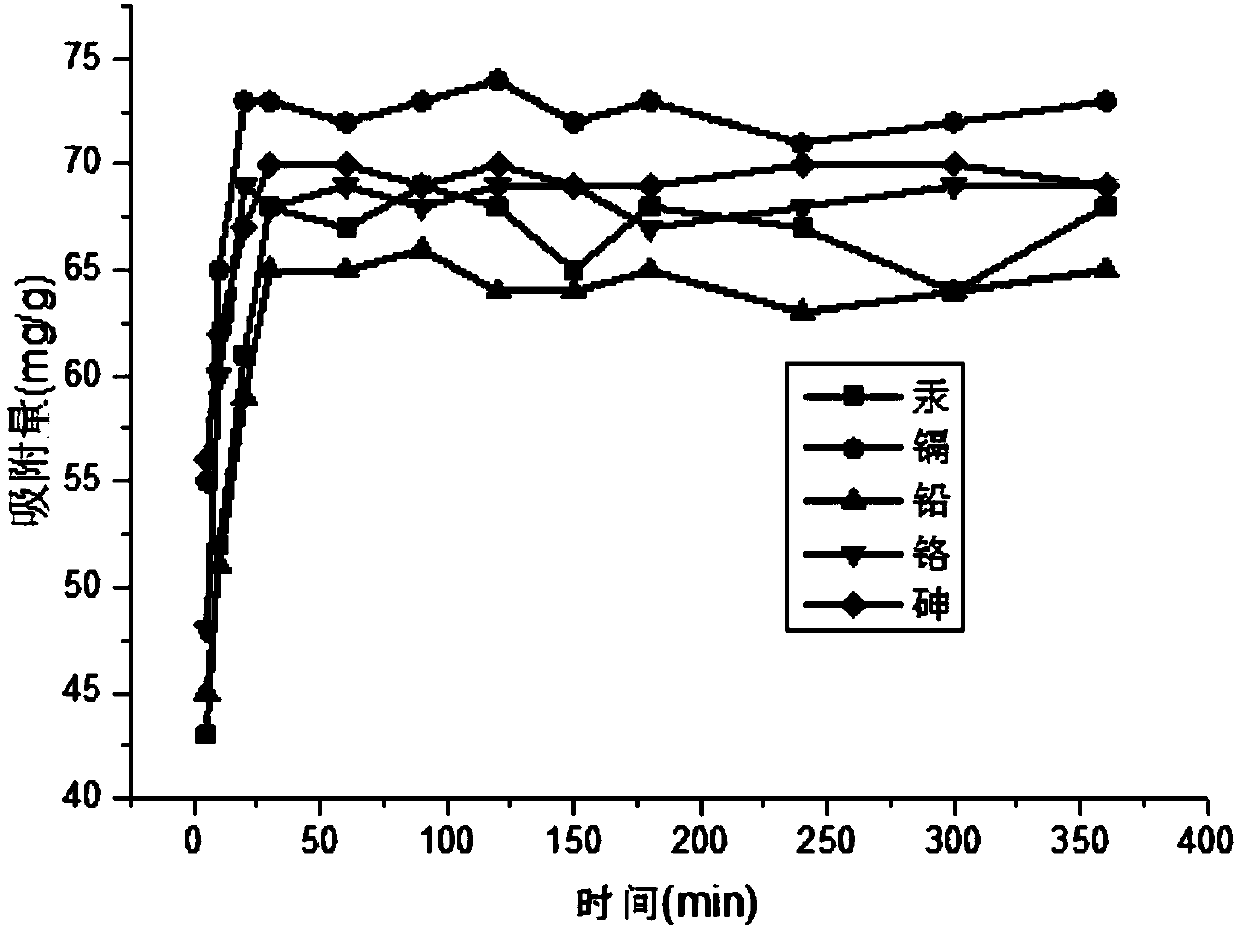

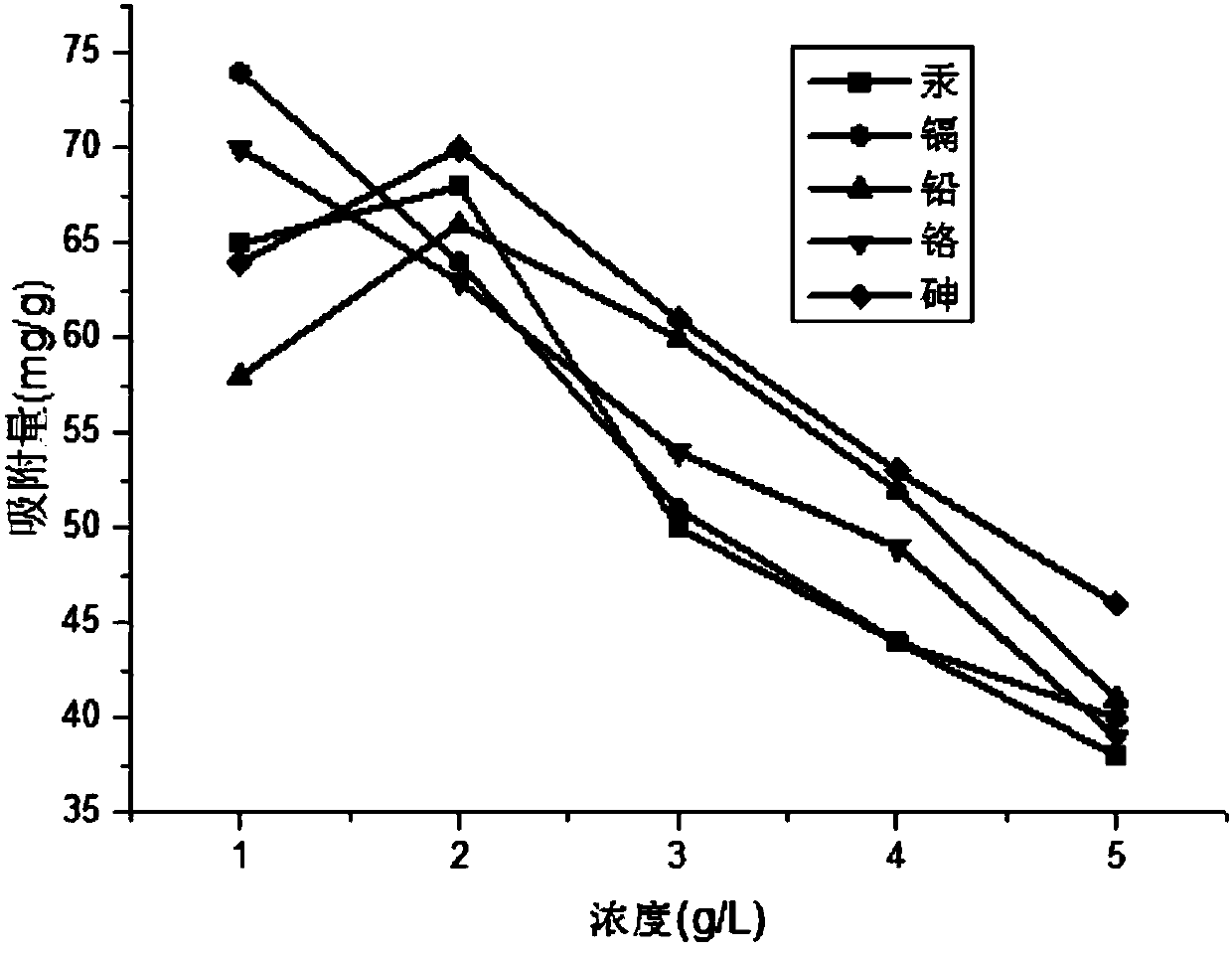

InactiveCN108031445ABest Adsorption EnvironmentHigh adsorption rateOther chemical processesWater contaminantsHigh concentrationWastewater

The invention discloses a preparation method of a pichia kudriavzevii adsorbent capable of quickly adsorbing heavy metal. In the preparation method disclosed by the invention, a high-concentration pichia kudriavzevii solution can be obtained by a supplementary material batch culture mode, and the pichia kudriavzevii adsorbent can be prepared by mixing and boiling the pichia kudriavzevii solution with a NaOH or HCl inorganic ligand solution. The pichia kudriavzevii adsorbent can be applied to adsorbing heavy metal of mercury, cadmium, lead, chromium, arsenic and the like in wastewater. The invention further discloses a use method of the adsorbent. Adsorption characteristics of the pichia kudriavzevii adsorbent are researched from four aspects of inorganic ligand pretreatment, adsorption time, adsorption thallus concentration and adsorption temperature, and heavy metal ion adsorbing modes and the best adsorption environment of the pichia kudriavzevii are explored.

Owner:合肥郑国生物科技有限公司 +1

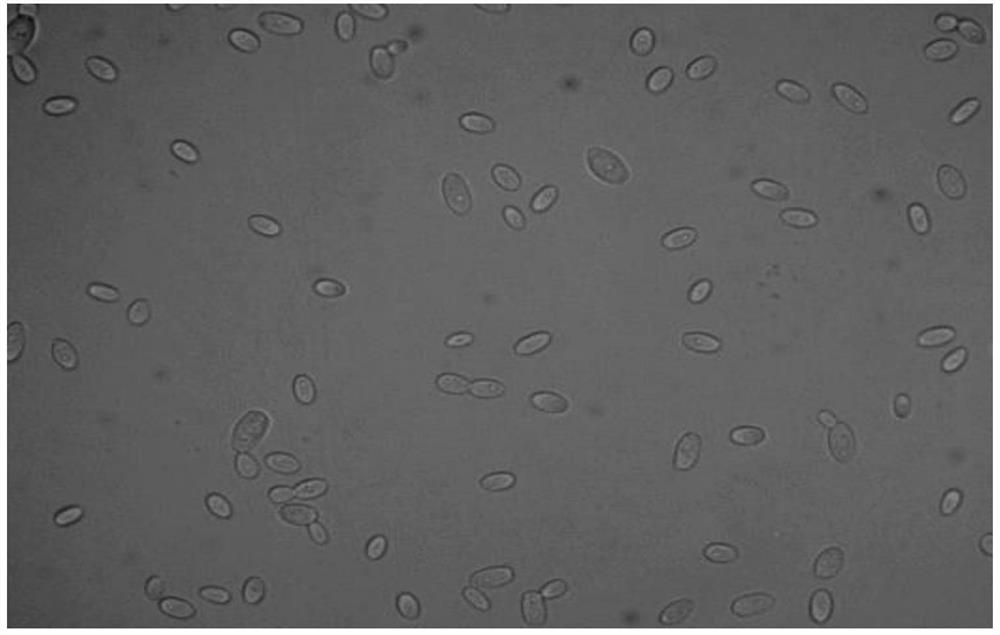

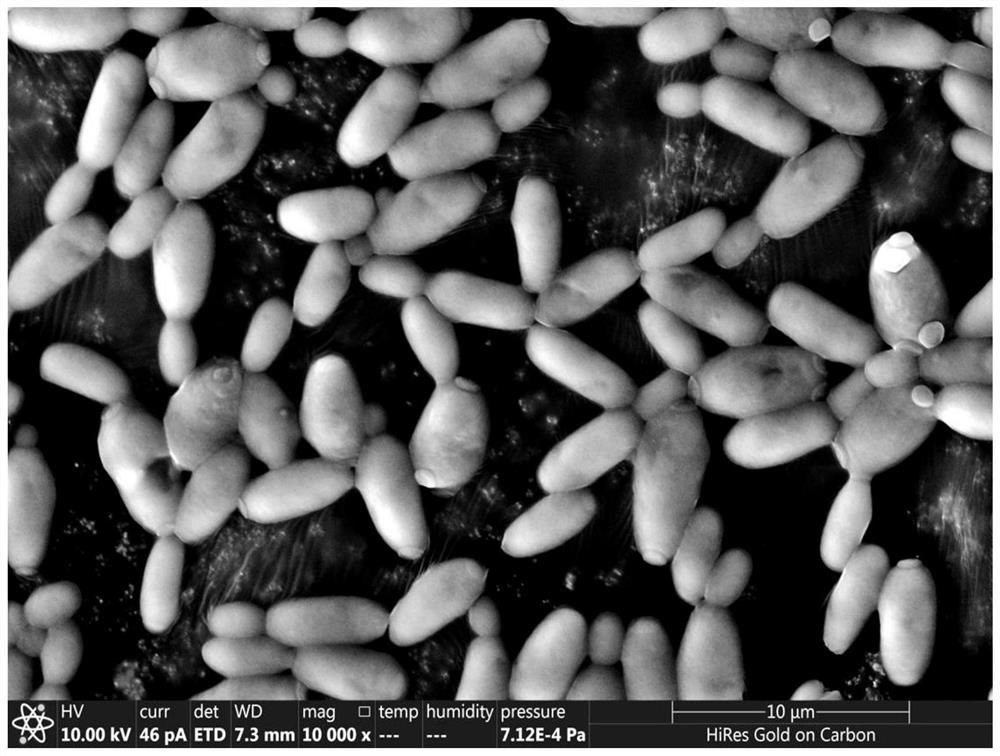

Pichia kudriavzevii strain (Pichia kudriavzevii) capable of producing beta-phenethyl alcohol, culture method and application of pichia kudriavzevii strain

ActiveCN111534445AIncrease productionImprovement ingredientsFungiMicroorganism based processesMicroorganismPhenethyl alcohol

The invention discloses a pichia kudriavzevii strain (Pichia kudriavzevii) capable of producing beta-phenethyl alcohol, a culture method and application of the pichia kudriavzevii strain. The strain is preserved in the China General Microbiological Culture Collection Center on April 26, 2020, and the preservation number of the strain is CGMCC No.19729; the strain has good sugar tolerance, ethanoltolerance and phenethyl alcohol tolerance, and is wide in growth pH and temperature range; the strain can be used for biologically converting L-phenylalanine to prepare beta-phenylethanol, and detection shows that the yield of the beta-phenylethanol of the strain can reach 5.09 g / L, so that the application of the strain in industrial production of beta-phenylethanol is facilitated, and the strainhas the advantages of mild reaction conditions, no seasonal influence, relatively short period, relatively low cost, no pollution and the like.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Method for preparing pickled papaya brewed wine from brown sugar and pickled papaya

InactiveCN107916195AHas a burnt aromaUnique tasteAlcoholic beverage preparationMicroorganism based processesPichia pastorisPapaya family

The invention discloses a method for preparing pickled papaya brewed wine from brown sugar and pickled papaya. The Kud pichia pastoris yeast strain classification name is Pichia Kudriavzevii YNCA9066,with a preservation serial number of CCTCC NO:M2017377. The bacterial strain liquid seed is inoculated to a brown sugar and pickled papaya juice system with mass percentages of 5-20% and 10-30% respectively for anaerobic fermentation, and the pickled papaya brewed wine is obtained after the fermentation product undergoes filtering for deslagging and degerming. The obtained fermented pickled papaya wine has fruity fragrance with slight costustoot, scorch aroma of brown sugar and thick winey fragrance, and is pure in taste, moderate in sour and sweet taste and unique in mouthfeel. The raw material source is rich, and the bacterial strain is steady in character, and easy to preserve, activate and ferment. The production process is simple, operability, standardization and controllability arestrong, large-scale industrial production is easy to realize, and therefore, the pickled papaya brewed wine has good development and application prospects.

Owner:YUNNAN MINZU UNIV

Method for preparing elaeagnus conferta roxb brewed wine from brown sugar and elaeagnus conferta roxb

InactiveCN107916194AHas a burnt aromaUnique tasteMicroorganism based processesAlcoholic beverage preparationFruit juiceAspergillus oryzae

The invention discloses a method for preparing elaeagnus conferta roxb brewed wine from brown sugar and elaeagnus conferta roxb. The aspergillus oryzae strain classification name is Pichia kudriavzevii YNCA9066, with preservation serial number of CCTCC NO:M 2017377. The bacterial strain liquid seed is inoculated to a brown sugar and elaeagnus conferta roxb juice system with mass percentages of 5-20% and 10-30% respectively for anaerobic fermentation, and the elaeagnus conferta roxb brewed wine is obtained after the fermentation product undergoes filtering for deslagging and degerming. The obtained fermented elaeagnus conferta roxb wine has fruity fragrance with slight costustoot and scorch aroma of brown sugar, and is pure in taste, moderate in sour and sweet taste and unique in mouthfeel.The raw material source is rich, and the bacterial strain is steady in character, and easy to preserve, activate and ferment. The production process is simple, operability, standardization and controllability are strong, large-scale industrial production is easy to realize, and therefore, the elaeagnus conferta roxb brewed wine has good development and application prospects.

Owner:YUNNAN MINZU UNIV

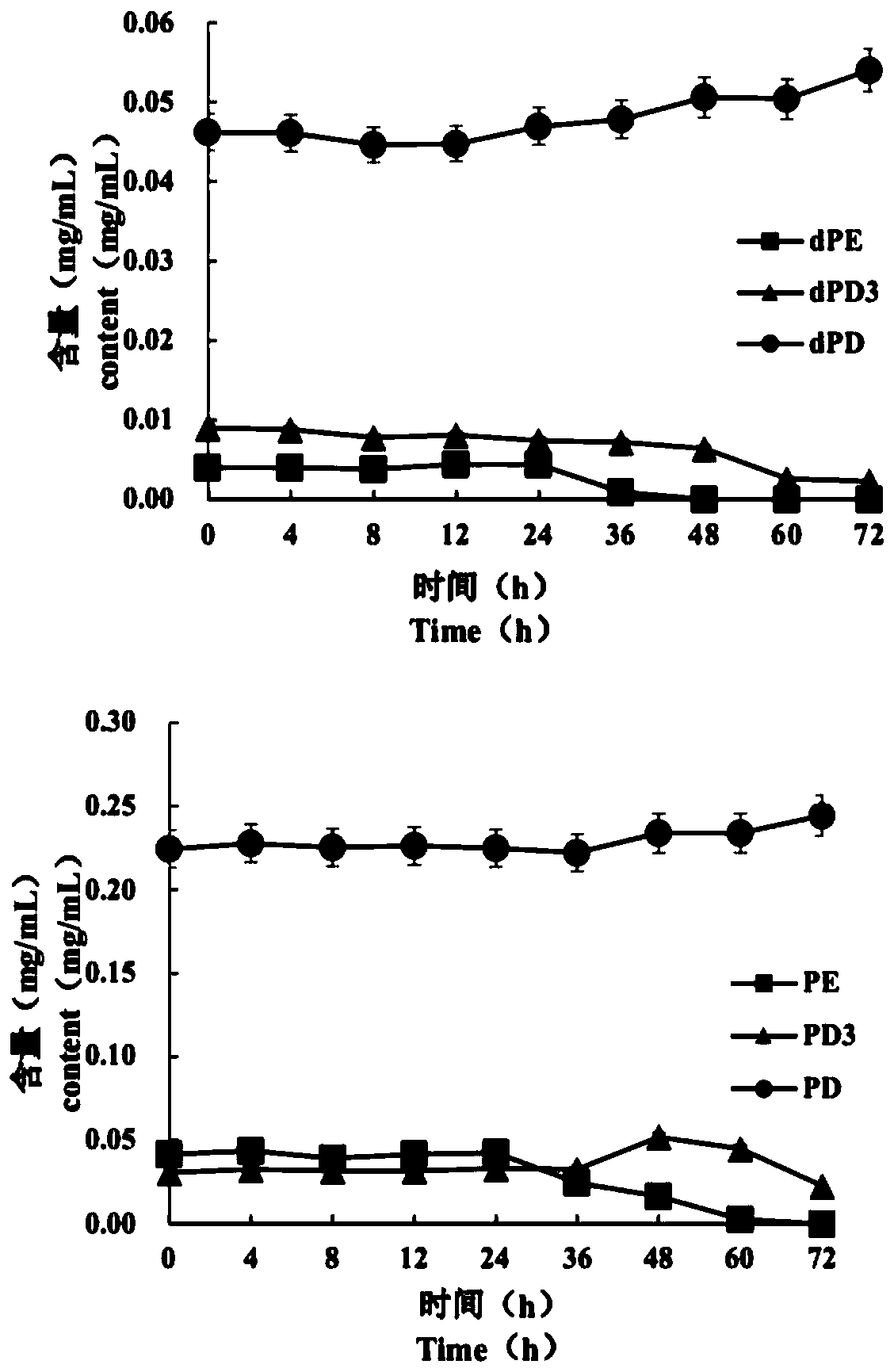

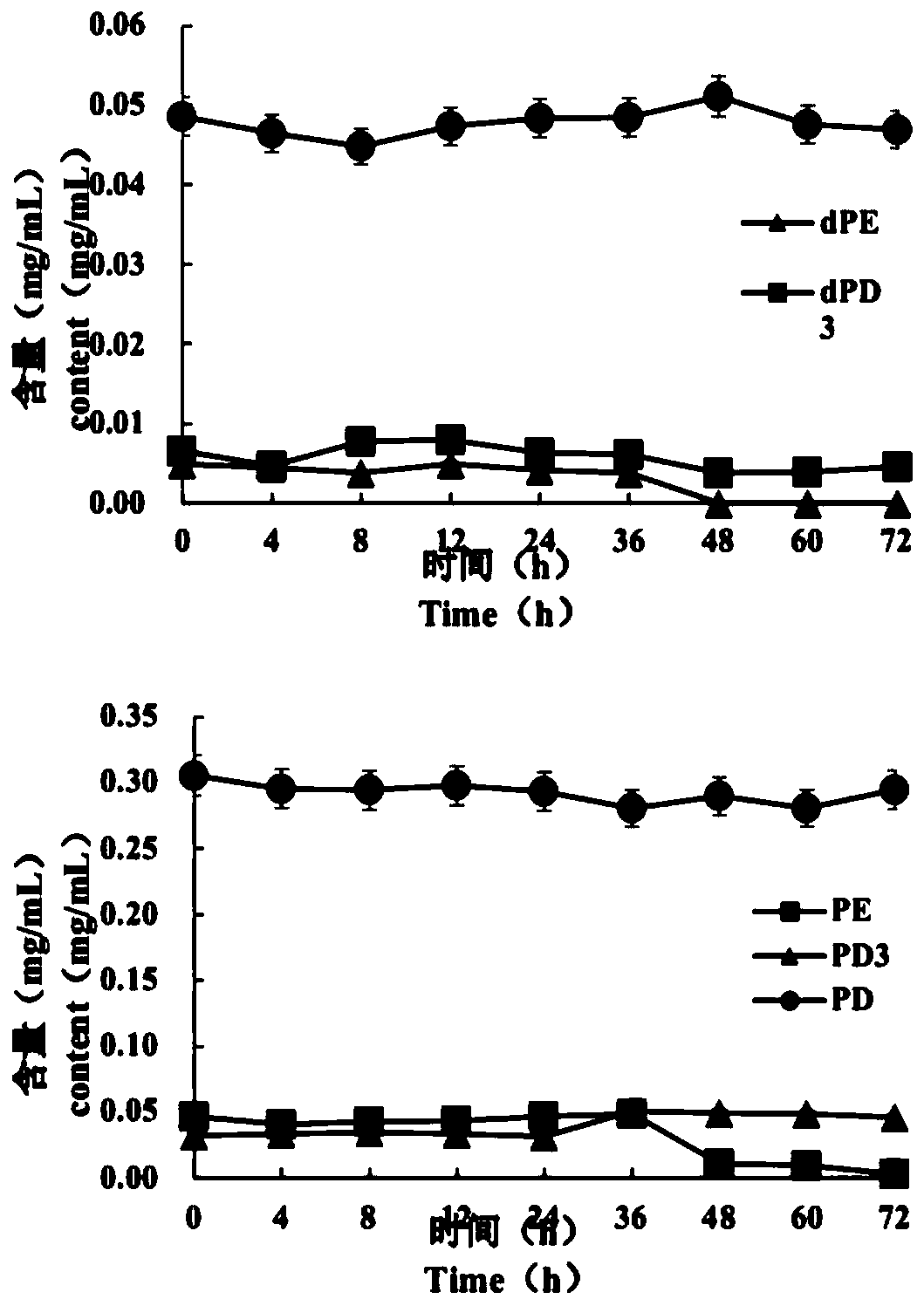

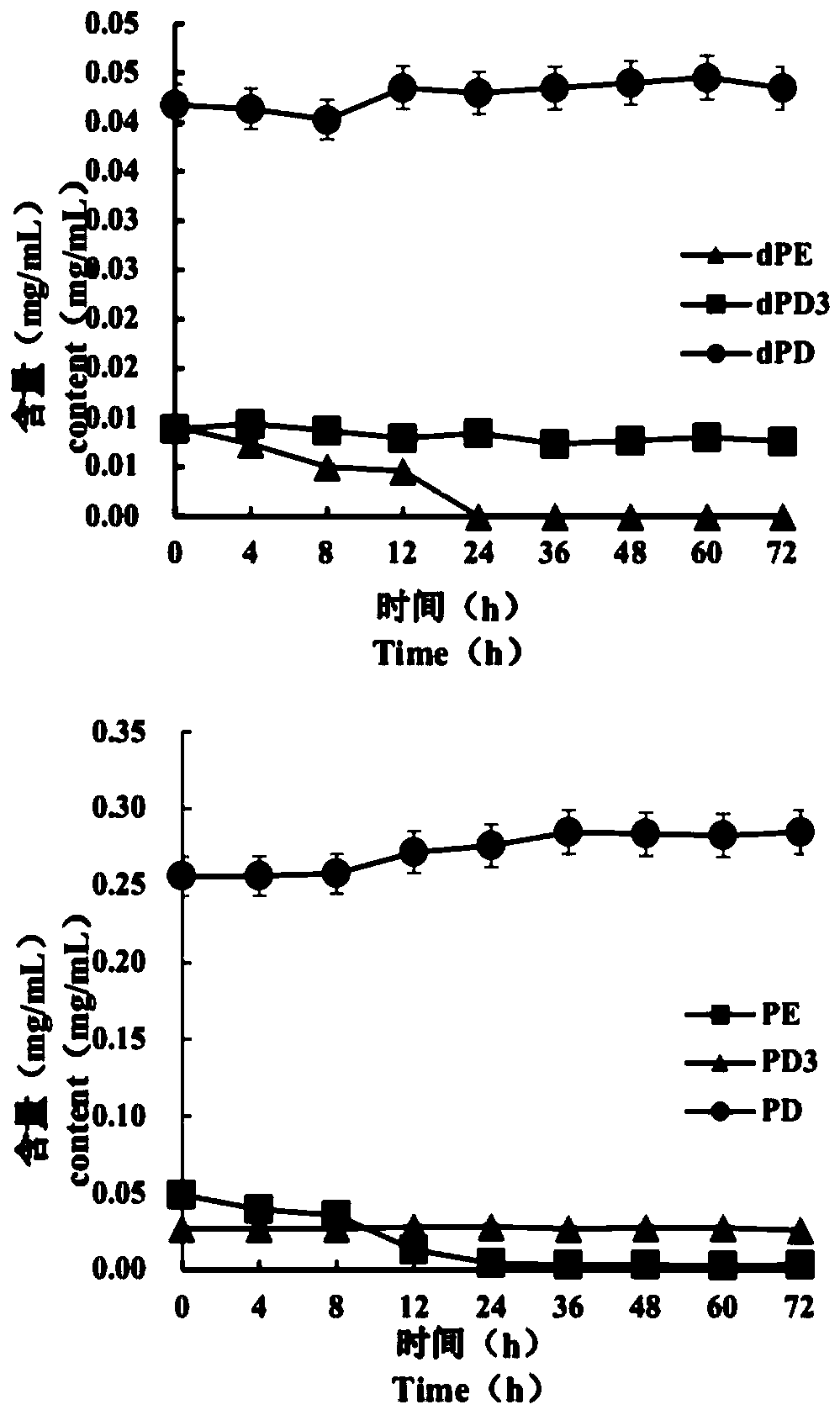

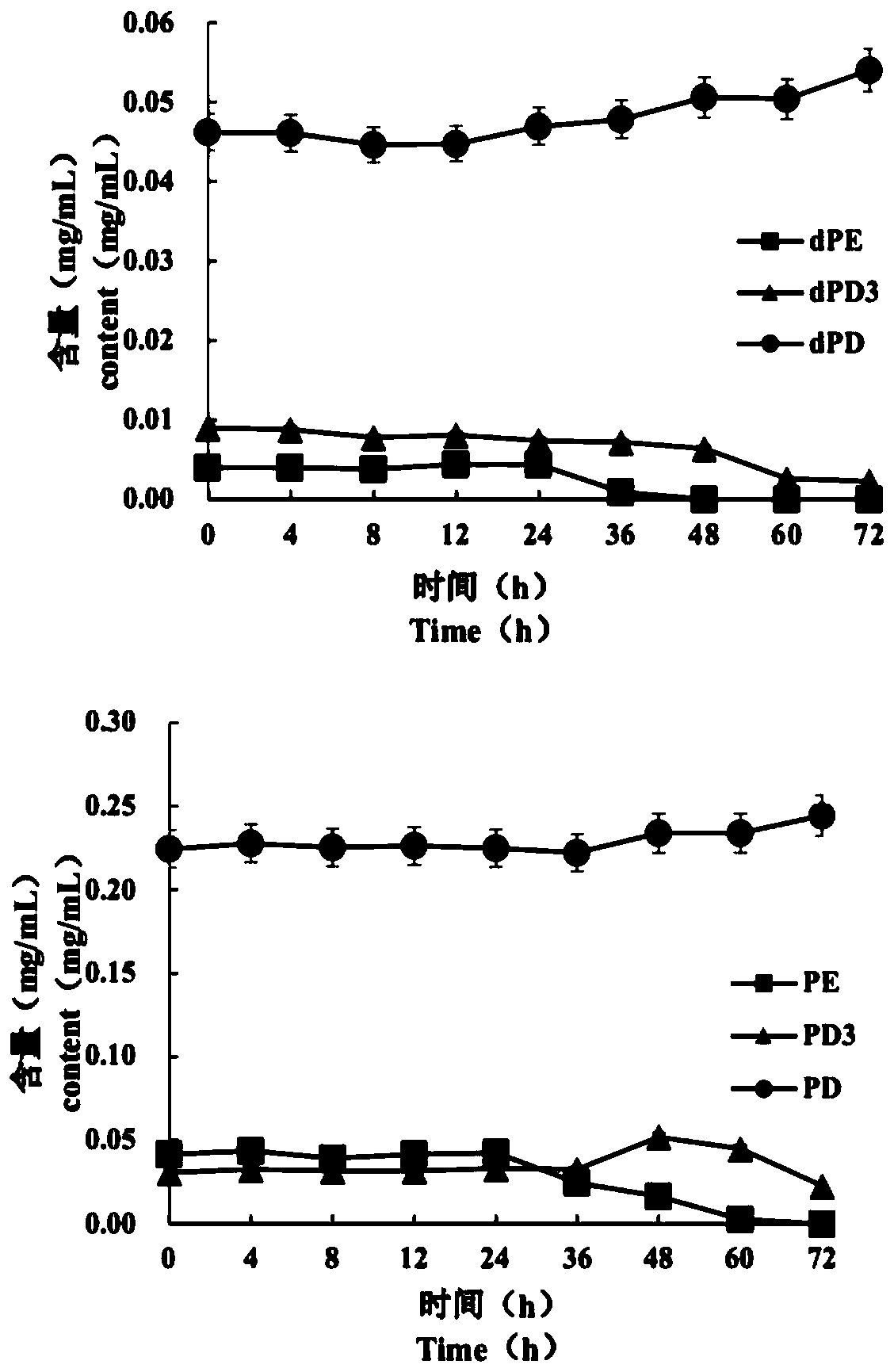

Preparation method and application of deapio-platycodin D

PendingCN111394266APromote safe productionHigh yieldOrganic active ingredientsFungiBiotechnologyBacterial strain

The invention belongs to a preparation method of deapio-platycodin D. The preparation method for preparing the deapio-platycodin D is characterized in that the deapio-platycodin D is prepared by two or more bacterial strains, including a pichia kudriavzevii bacterial strain and a bacillus velezensis bacterial strain. According to the preparation method, two bacterial strains of different transformation mechanisms are used for the first time, and platycodin is transformed in a mixed fermentation manner, so that the yield of the deapio-platycodin D is effectively increased. Biotransformation ofthe platycodin is performed through the fermentation characteristics of the bacterial strains, so that safe and environment-friendly production of the platycodin can be realized, platycodon resourcescan also be sufficiently used, and the platycodin being low in bioactivity contained in the platycodon resources is transformed into saponin being high in bioactivity, and the effect of turning wasteinto wealth is achieved.

Owner:YANBIAN UNIV

Preparation method and application of platycodin D

ActiveCN111394265APromote safe productionImprove biological activityOrganic active ingredientsFungiBiotechnologyBacterial strain

The invention belongs to a preparation method for platycodin D, and adopts a mixed bacterial strain which includes a Pichia kudriavzevii bacterial strain and a Bacillus velezensis bacterial strain toprepare the platycodin D. According to the preparation method, two types of bacterial strains with different conversion mechanisms are used for the first time to convert platycodin in a mixed fermentation way, and the yield of the platycodin D and deapioplatycodin D can be effectively improved. By use of bacterial strain fermentation characteristics, the platycodin can be subjected to biological transformation, the safe and environmentally-friendly production of the platycodin can be realized, platycodon grandiflorum resources can be fully utilized, and the platycodin which is contained in theplatycodon grandiflorum resources and has low biological activity can be converted into saponin with high biological activity so as to achieve an effect of recycling waste materials.

Owner:YANBIAN UNIV

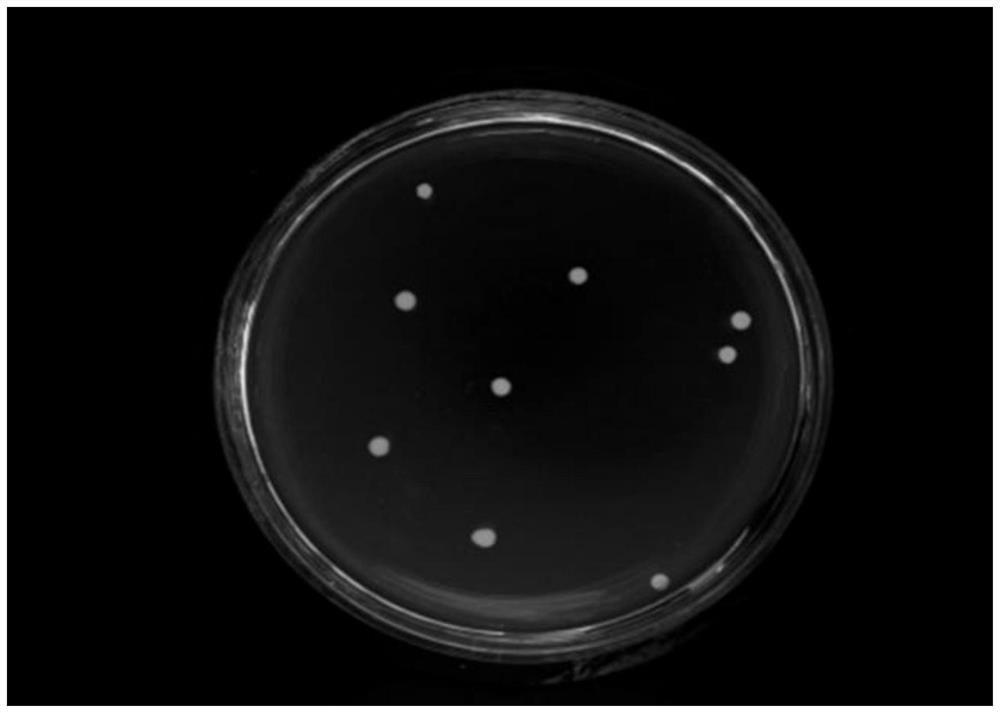

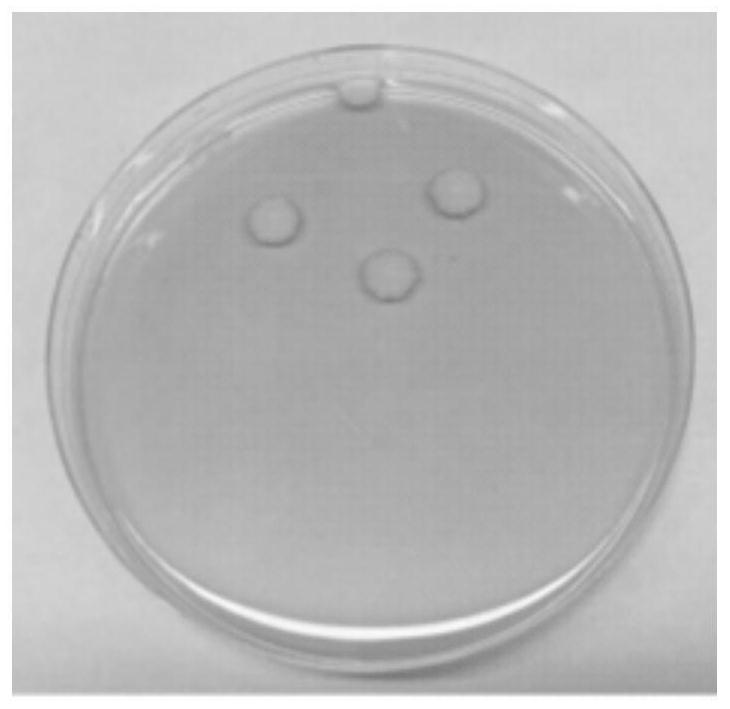

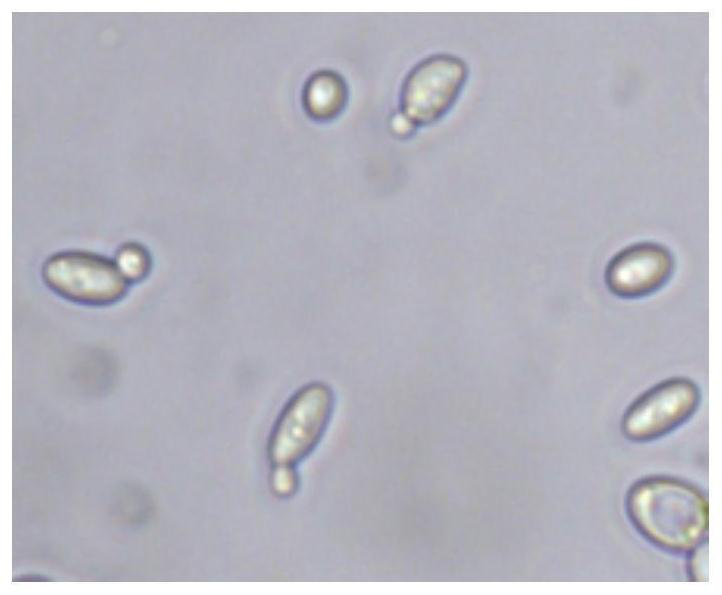

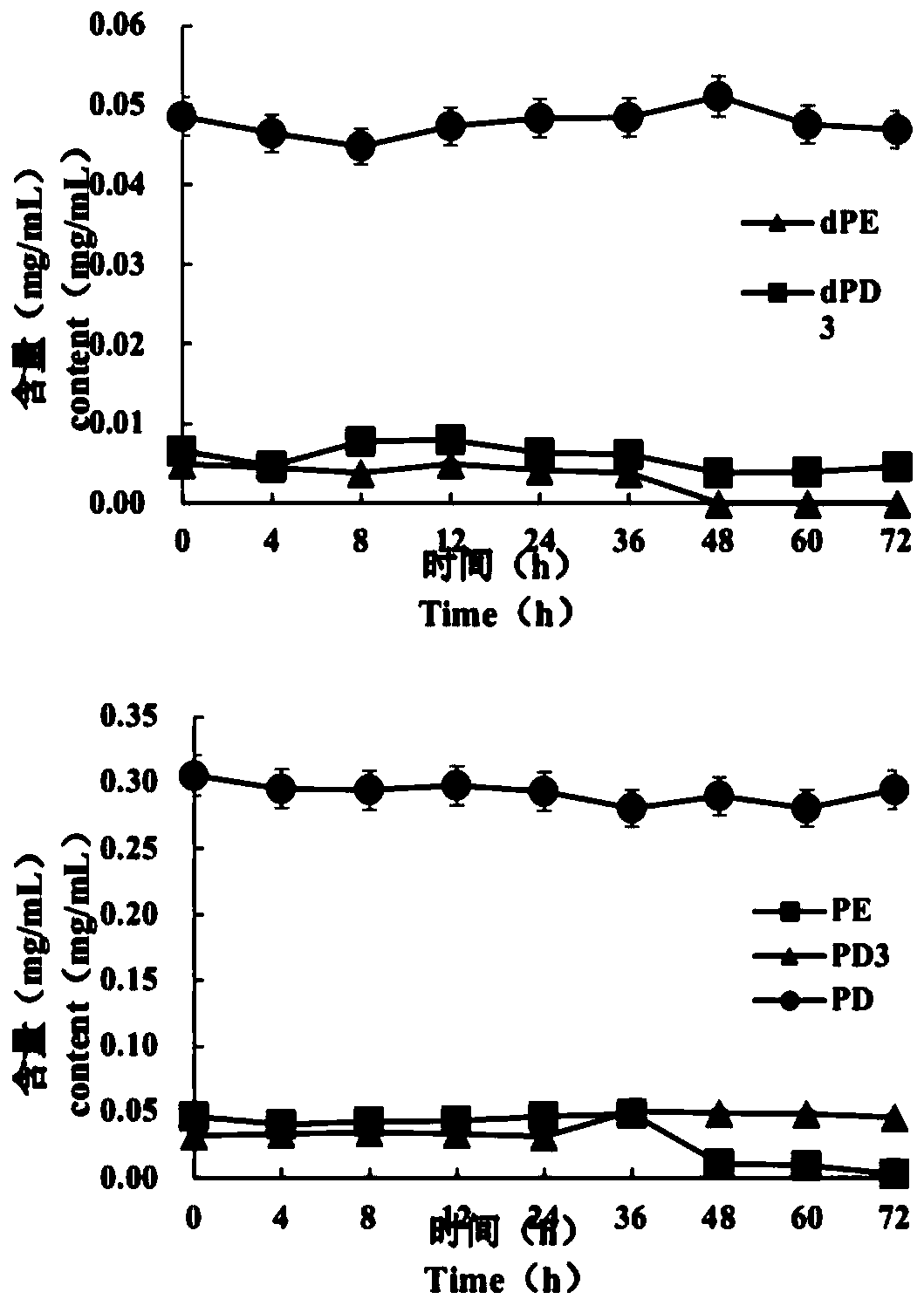

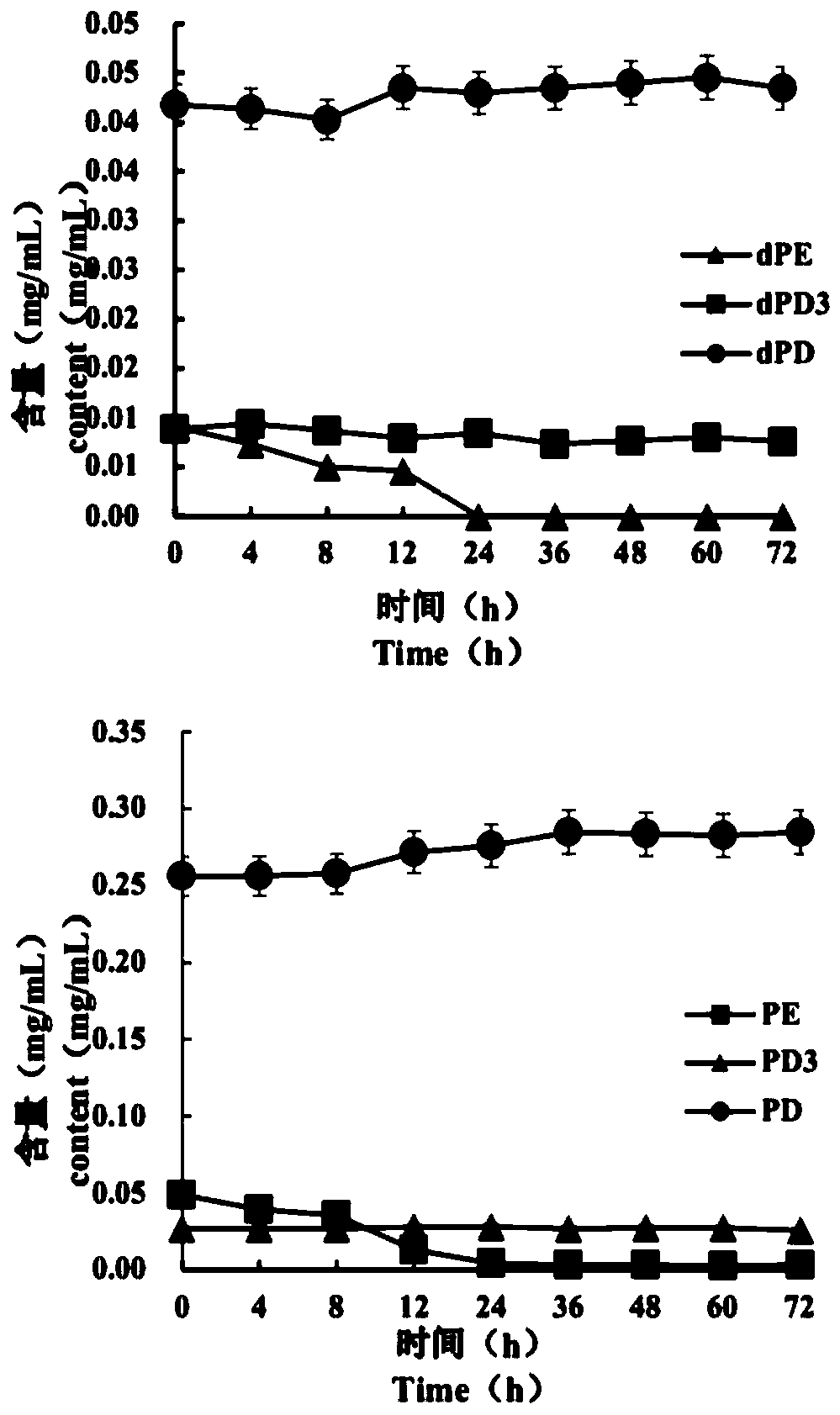

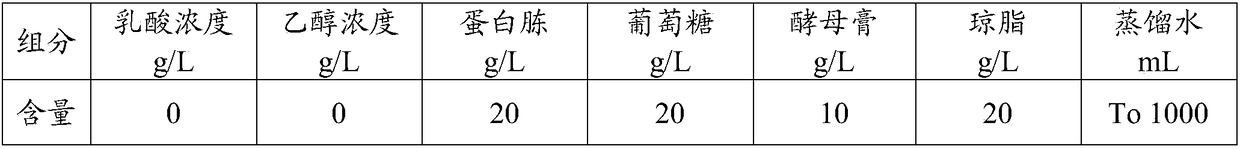

Selective culture medium for quantitative detection of pichia kudriavzevii and preparation method and application thereof

ActiveCN108588172ALow pHAccurate quantitative detectionMicrobiological testing/measurementHigh concentrationCulture mediums

The invention discloses a selective culture medium for quantitative detection of pichia kudriavzevii, and a preparation method and application thereof. Each liter of the selective culture medium comprises the following components: 20-40g of lactic acid; 20-40g of ethanol; 10-20g of peptone, 5-15g of yeast extract; 1-5g of MgSO4;0.5-1.5g of NaCl; 0.1-1g of FeSO4; 15-20g of agar, the balance being distilled water, and the natural pH is 3.0-0.5, as the selective medium is for the characteristics of the pichia kudriavzevii; wherein a high concentration of lactic acid and an amount of ethanol are added so that the pH of the selective medium is relatively low; the selective culture medium can effectively inhibit the growth of other microorganisms in the brewing process of the white spirit; the purpose of fast and accurate quantitative detection of the pichia kudriavzevii can be achieved by the selective culture medium.

Owner:KWEICHOW MOUTAI COMPANY

Method for preparing Docynia delavayi fruit wine from brown sugar and Docynia delavayi fruits

InactiveCN108048275AHas a burnt aromaUnique tasteAlcoholic beverage preparationMicroorganism based processesFruit wineFruit juice

The invention discloses a method for preparing Docynia delavayi fruit wine from brown sugar and Docynia delavayi fruits. The Pichia kudriavzevii strain is named as Pichia kudriavzevii YNCA9066 and hasa preservation number of CCTCC NO: M 2017377. The method comprises inoculating a system containing 5-20% by mass of brown sugar and 10-30% of a Docynia delavayi fruit juice with a strain liquid seed,carrying out anaerobic fermentation, and filtering the fermented product to remove slag and bacteria so that the Docynia delavayi fruit wine is obtained. The Docynia delavayi fruit wine has a wood-fruit flavor, a brown sugar coke flavor and a thick wine flavor, a pure taste, moderate acidness and sweetness and a unique taste. The method utilizes abundant raw materials. The strain has stable characters and is easy to preserve, activate and ferment. The method has simple processes, strong operability, standardization and controllability, is easy to industrialize in a large scale and has a gooddevelopment and application prospect.

Owner:YUNNAN MINZU UNIV

Method for removing cyanide from rubber seeds through composite fermentation

ActiveCN105410358AThe detoxification effect of compound fermentation is goodIncrease the fragranceFungiBacteriaLactobacillusCyanide

The invention discloses a method for removing cyanide from rubber seeds through composite fermentation. According to the method, the composite fermentation of Pichia kudriavzevii (Pichia kudriavzevii) and Weissella confusa (Weissella confusa) is adopted for removing the cyanide from the rubber seeds. The method comprises the following steps of separately performing activated culture on the Pichia kudriavzevii and the Weissella confusa until the effective viable count is greater than or equal to 1010CFU / mL, performing mixing so as to obtain a mixture, and adding the mixture to culture mediums which are obtained by mixing water and crushed rubber seed kernels for culture. Through research, researchers find that the composite fermentation is beneficial to cyanide removing effects, and the average cyanide removing rate is 88.9% or above. Lactic acid bacteria produce acid, so that the growth of infectious microbes can be restrained; fragrance is enhanced through the fermentation of yeast; therefore, under the premise that the unchanged quality of the rubber seeds is guaranteed, the cyanide is effectively removed.

Owner:KUNMING UNIV OF SCI & TECH

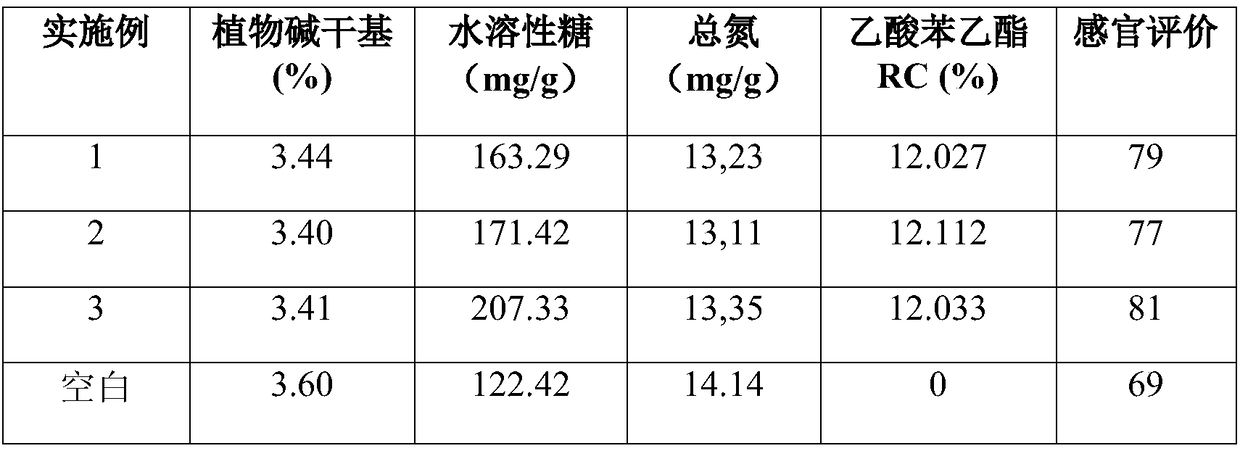

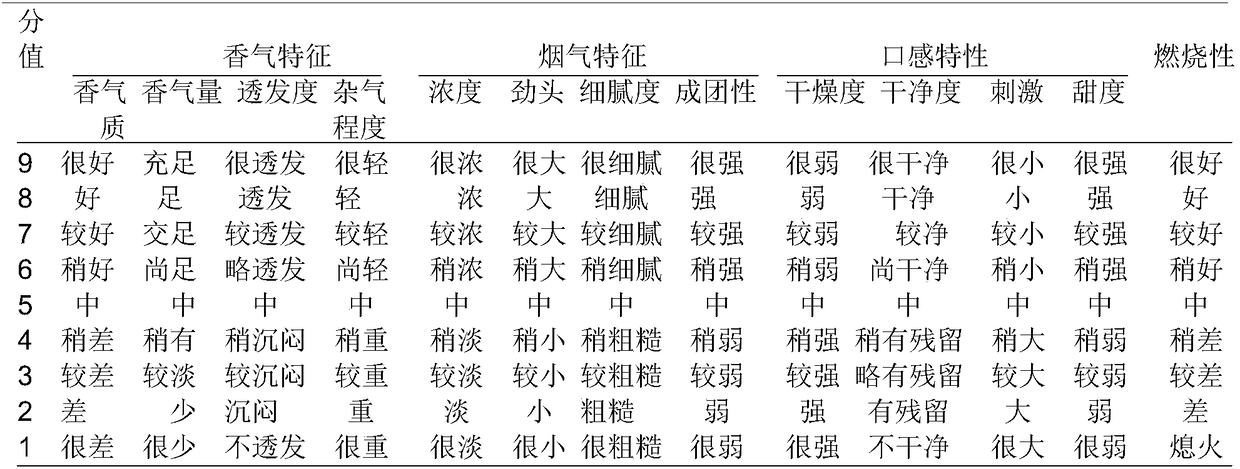

Method for utilizing pichia kudriavzevii to ferment tobacco

The invention discloses a method for utilizing pichia kudriavzevii to ferment tobacco. The method includes the following steps of inoculating pichia kudriavzevii FBKL 2.0008 strains on a sloped culture medium for culturing at 28 DEG C for 24-48 hours until fungi grow all over test tubes; making the strains which are cultured on a slope activated on lines drawn on a wort agar culture medium and culturing the strains for 24-48 hours at 28 DEG C; preparing seed liquid, wherein 0.4 ml / g of bacterial solution is added into the tobacco, 0.2 ml / g of sterile water is added into the tobacco every threedays, and the tobacco is placed in an environment at 28-30 DEG C for 15-20 days and dried at the low temperature of 40-60 DEG C for 15-30 min to obtain the seed liquid. The tobacco prepared accordingto the method has the fragrance of roses, aromatic powder and honey.

Owner:GUIZHOU UNIV

Probiotic flavor yogurt tablets

InactiveCN108782752AImprove the problem of taste discomfortAdd flavorMilk preparationLactobacillusProduct inspectionFood flavor

The invention belongs to a processing method of probiotic flavor yogurt tablets. The processing method includes the following steps: subjecting fresh milk, proteins, dry matters and other raw materials to sterilization, carrying out inoculated fermentation, milk curdling, secondary inoculated fermentation, tablet compressing, drying and end product inspection, etc. According to the invention, a flavor yeast (Pichia kudriavzevii N-X) is screened from traditional Kazakh handmade cheeses, and the flavor yeast (Pichia kudriavzevii N-X), preserved in China Center for Type Culture Collection, is used in the secondary inoculated fermentation. The flavor yeast is added in the process of making probiotics milk tablets, the traditional handmade process is improved, and auxiliary materials are added,so that the prepared probiotic flavor yogurt tablets are good for health and improved in product mouthfeel and flavor. Besides the function of the probiotic to the human body, the mouthfeel of the probiotic flavor yogurt tablets is more suitable for the needs of a large number of consumers in China.

Owner:SHIHEZI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com