Pichia kudriavzevii resistant to high temperature and stress and high in ethanol yield and application thereof

A technology of yeast and ethanol, which is applied in the field of Pichia pastoris, can solve the problems of inability to grow, produce ethanol, and inability to produce ethanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The isolation and identification of embodiment 1 bacterial strain

[0026] 1.1 Sample collection

[0027] Samples of yeast strains collected from subtropical rotting fruit.

[0028] 1.2 Isolation of strains

[0029] The collected samples were inoculated into enrichment medium YPD (containing 10% glucose, 2% peptone and 1% yeast extract), and incubated at 42° C. for 24 hours. Take 100 μL of the culture and evenly spread it on a plate containing 2% glucose, 2% peptone and 2% agar, and incubate at a constant temperature of 42°C for 24 hours. A single colony on the plate was inoculated into a test tube containing 3 mL of YPD and cultured at 42° C. for 24 hours to measure ethanol production. The strain with the highest ethanol production was selected for identification.

[0030] 1.3 Extraction of strain DNA

[0031] Inoculate a single colony of the strain to be identified in 15 mL of YPD and culture for 24 hours, centrifuge at 3000g for 10 minutes, discard the supernata...

Embodiment 2

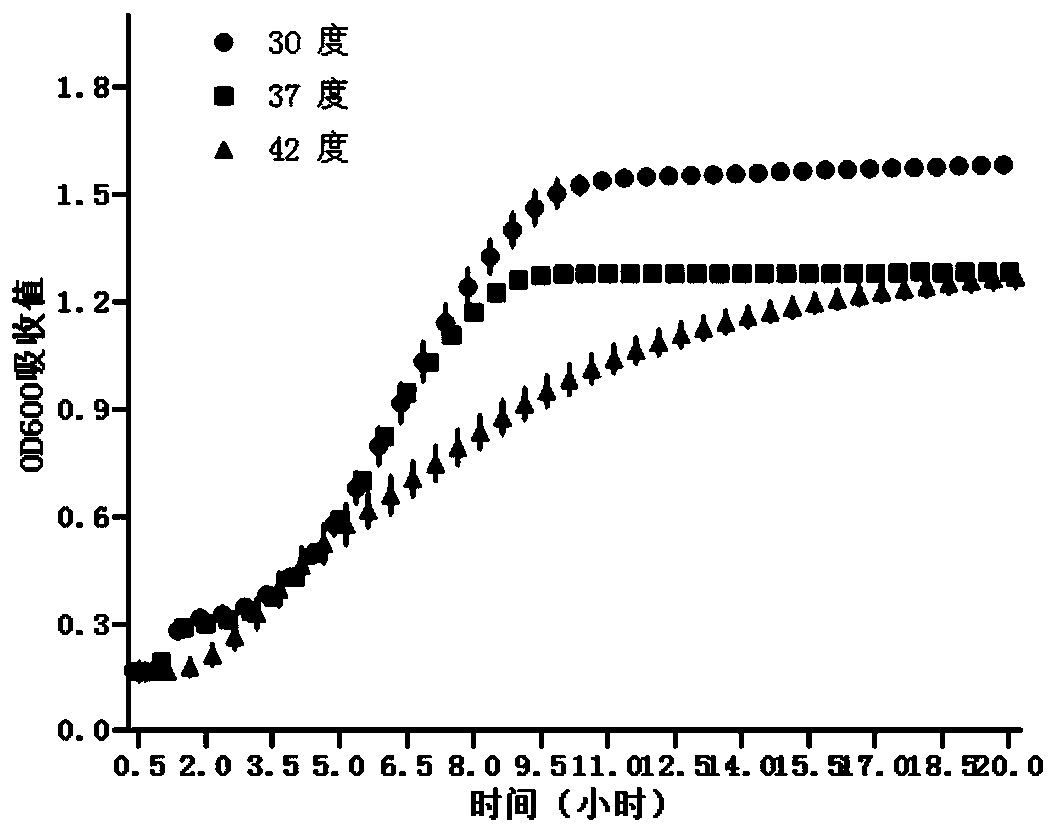

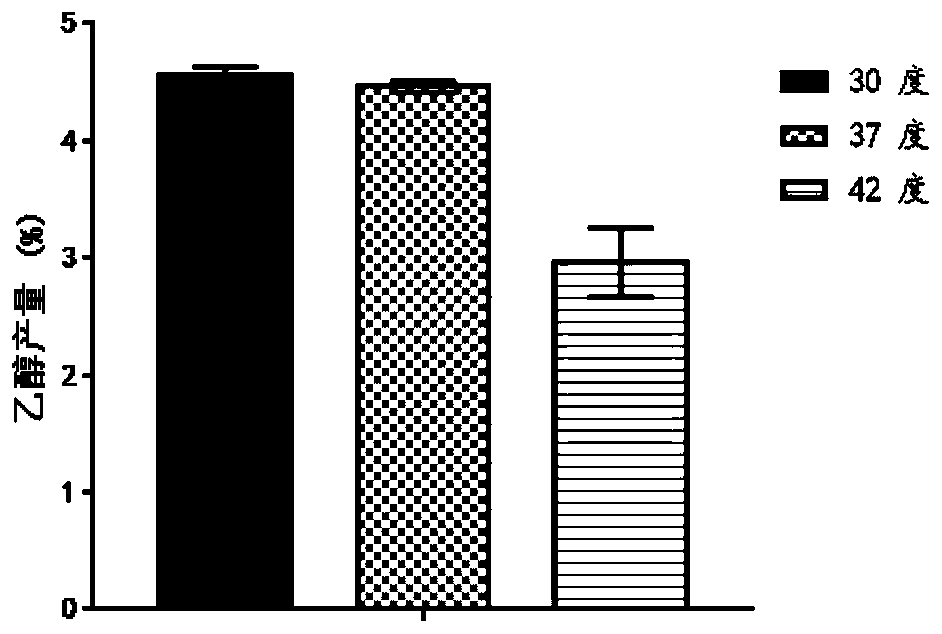

[0037] Embodiment 2 investigates the characteristic of isolated bacterial strain

[0038] The isolated strains were divided into single colonies on the plate, and a single colony was inoculated into 3mL YPD medium for overnight cultivation. Take the overnight culture to measure OD600 and dilute it to 0.2, inoculate 200 μL of culture with OD600 of 0.2 into a 10 mL fermentation tube, give a small amount of oxygen supply conditions, culture at different temperatures at 200 rpm for different times, take out 1 mL and use high performance liquid phase method to measure and calculate ethanol concentration percentage.

[0039] The growth curves of strains under different temperature, ethanol, formic acid, furfural, hydrogen peroxide and acetic acid stress were determined by turbidimetric method. The specific steps are: inoculate a single colony into 3mL YPD medium and cultivate overnight, take the overnight culture to measure OD600, dilute it to OD600 with YPD medium without additive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com