Pichia kudriavzevii yeast low in urea yield and capable of producing flavor and application thereof to food fermentation

A technology for yeast and food, applied in the field of wine brewing and food safety, to reduce the formation of urea and EC, and to produce strong flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Screening and identification of yeast Pichia kudriavzevii with low urea production

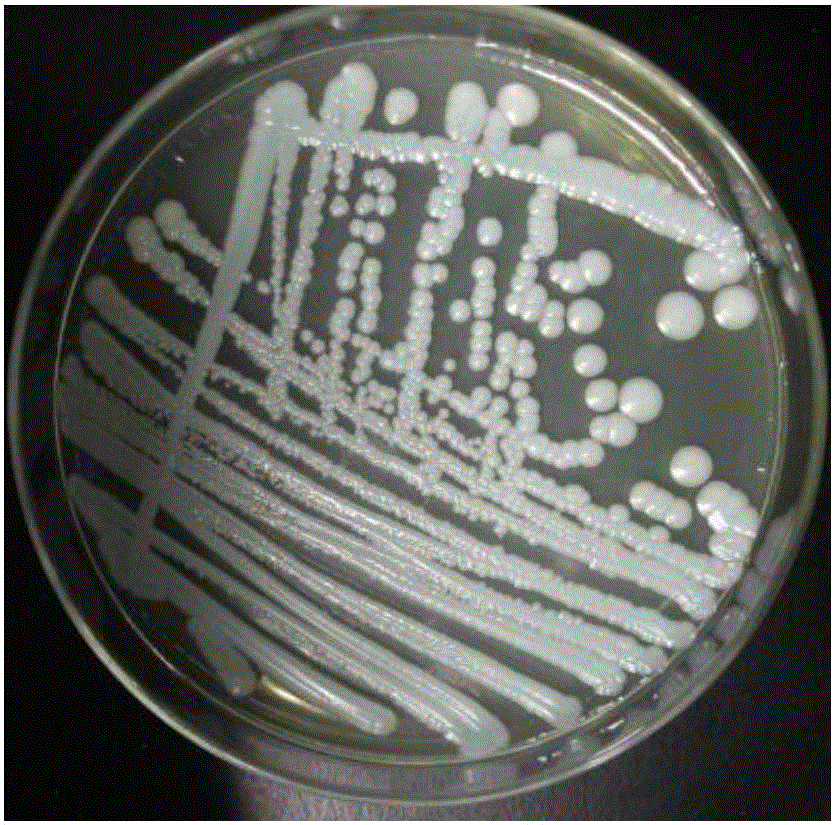

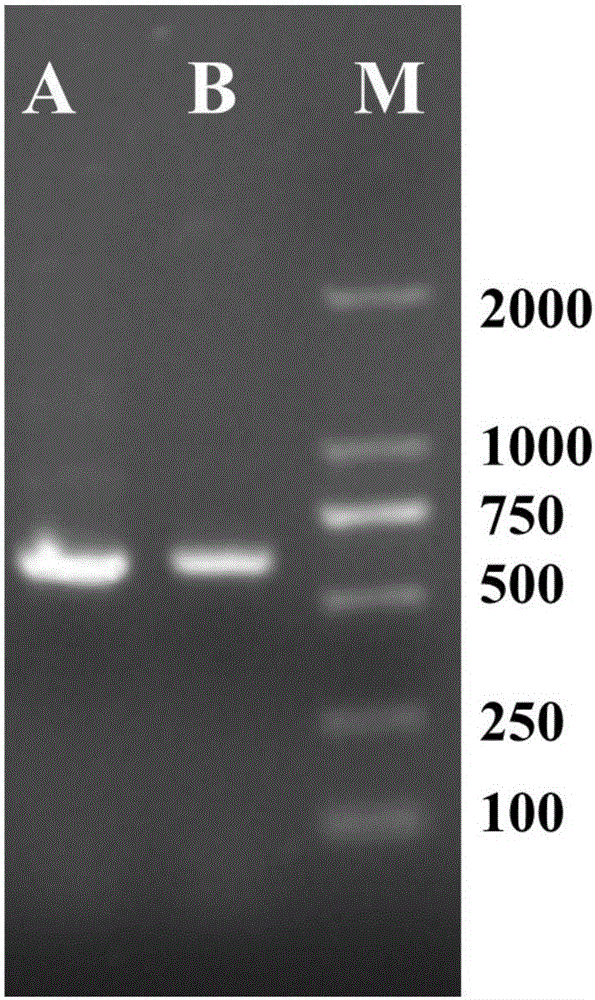

[0034] Get 10g Daqu and dissolve it in 100ml sterile normal saline, shake it for 30min and carry out gradient dilution, coat WL solid plate, according to the morphological characteristics of colonies on the plate ( figure 1 ), pick a single colony of Pichia kudriavzevii yeast for high-throughput liquid fermentation, carry out molecular biology identification on the obtained potential low-urea-producing Pichia kudriavzevii yeast, and use yeast-specific classification and identification primers NL1 and NL4 to amplify the 26S rDNA fragments of the yeast respectively , gel electrophoresis detection ( figure 2 ). Sequencing comparisons were then performed to confirm that the screened low-urea-producing yeasts all belonged to Pichia kudriavzevii yeasts in taxonomy. Finally, a strain of Pichia kudriavzevii with low urea production was obtained, which was named Pichia kudriavzevii...

Embodiment 2

[0036] Embodiment 2: the function of bacterial strain metabolism producing flavor

[0037] Seed medium: Take a 25ml test tube, fill it with 5ml sorghum medium, and inoculate it with the strain Pichia kudriavzevii JZ523 obtained in Example 1 above, at natural pH, 30°C, 200rpm, and carry out aerobic culture for 48h.

[0038] Fermentation medium: Inoculate the cultivated seed culture medium into a 250ml Erlenmeyer flask containing 50ml sorghum medium, at natural pH, inoculum size is 5%, 30°C, 200rpm, ferment for 48h.

[0039] Using headspace solid-phase microextraction (HS-SPME) and gas chromatography-mass spectrometry (GC-MS) methods to analyze volatile products, take 8mL samples, put them into a headspace vial containing 3g NaCl, add 10 μL of 4-methyl-2-pentanol with a concentration of 42.60 mg / L was used as the internal standard. The headspace vial was extracted at a constant temperature of 50°C for 45 minutes, and analyzed by GC-MS after the extraction was completed.

[004...

Embodiment 3

[0041] Example 3: Pichia kudriavzevii JZ523 Yeast Low Production of Urea

[0042] Seed medium: take a 25ml test tube, fill it with 5ml sorghum medium, and inoculate the strain obtained in the above-mentioned Example 1, and carry out aerobic culture at natural pH, 30°C, 200rpm for 48h.

[0043] Fermentation medium: Inoculate the cultivated seed culture solution in a 250ml Erlenmeyer flask equipped with 50ml of sorghum medium (adding 500mg / L of arginine precursor and 2% ethanol), the inoculum size is 5%, 30°C , 200rpm, fermented for 96h, and measured the yeast growth situation (OD 600 ) and urea formation. It was found that the strain entered the stationary phase (OD 600 1.8), the maximum urea yield reached 227.42μg / L (48h) during the fermentation process.

[0044] Urea detection: the content of urea in the fermentation broth was determined by pre-column derivatization high performance liquid chromatography fluorescence detector (HPLC-FLD). The specific operation is as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com