Biological adsorption recycling method for heavy metal in industrial wastewater

A technology for industrial wastewater and biological adsorption, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as less research, and achieve the effect of simple process, stable performance and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

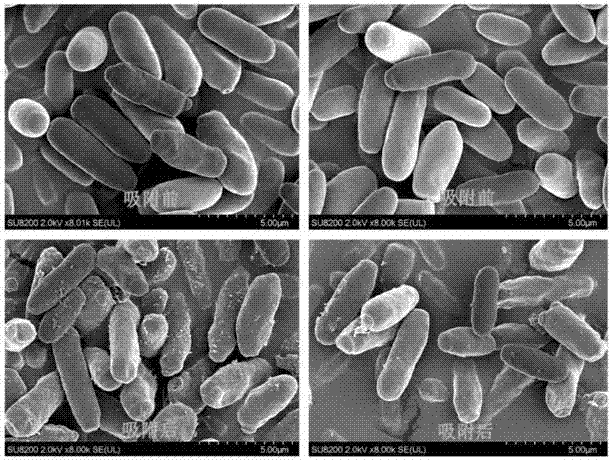

[0034] 2. Preparation of Pichia kurdori adsorbent:

[0035] (1) Activation culture of Pichia kurdori:

[0036] Inoculate the Pichia kurdori seed solution into the fermentation medium with a 10% (v / v) inoculum volume, the liquid volume is 45mL / 250mL, the shaker speed is 250r / min, and the temperature is cultivated at 25°C for 16h;

[0037] (2) Enrichment culture of Pichia kurdori:

[0038] Add 3.5L of fermentation broth to a 7L fermenter, the inoculum size is 12% (v / v), the initial stirring speed is 400r / min, the initial ventilation volume is 1.0vvm, the fermentation temperature is 24.5-25.5°C, and the pH is controlled to be less than 2 during the fermentation process. The dissolved oxygen in the process is maintained above 30%, the maximum stirring speed is set to 800r / min, and the maximum ventilation rate is 3.0 vvm. The feeding is started at the 6th hour of fermentation, and the feeding is done every 2 hours to make up the sugar concentration to 2%. According to the yeast po...

Embodiment 1

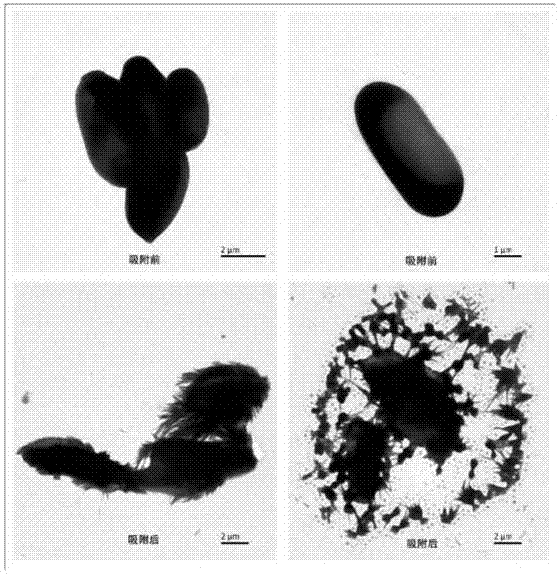

[0046] Use 0.1mol / L NaOH solution to heat and boil Pichia pastoris for 15 minutes, then centrifuge at 1000-3000rpm to collect the bacteria, put them into an oven for drying at 105°C, and grind them into powder for later use.

[0047] At the same time, the Pichia pastoris was heated and boiled for 15 minutes with an equal amount of aqueous solution, centrifuged at 3000-5000 rpm, the bacteria were collected, dried in an oven at 105°C, and ground into powder.

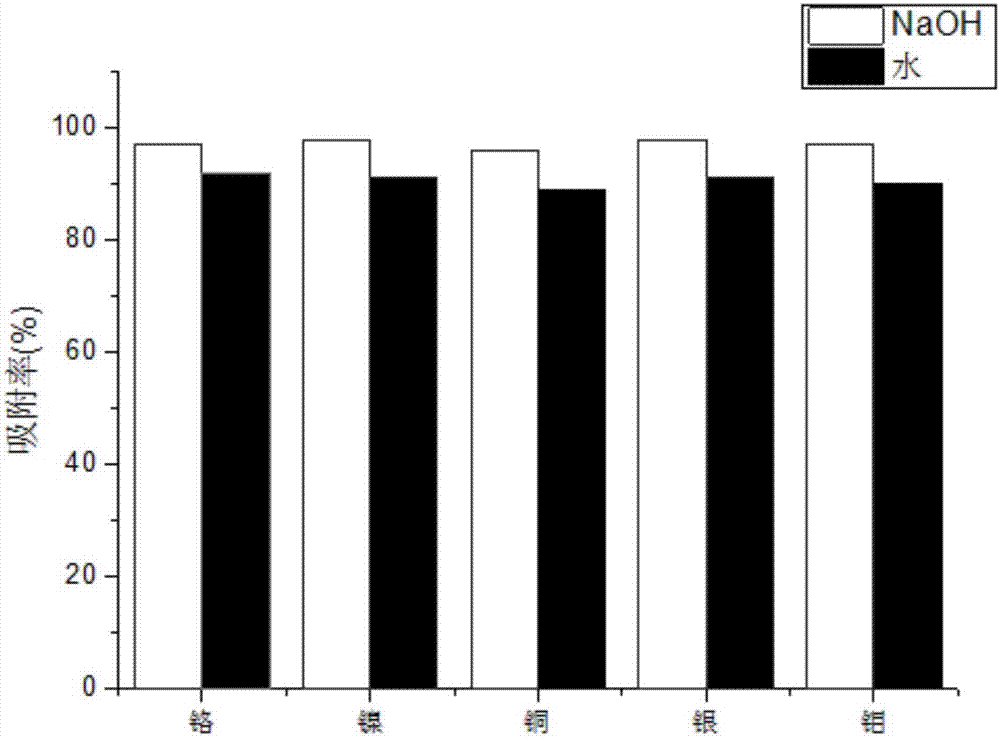

[0048] Take 100ml of actual industrial wastewater solution (the contents of chromium, nickel, copper, silver and molybdenum are 0.9 mg / L, 1.1 mg / L, 0.8 mg / L, 1.3 mg / L, 1.9 mg / L, pH=1.43) in the cone In a conical flask, take 0.1 g of the bacterial adsorbent powder collected by the above method and add them to the Erlenmeyer flask respectively, plug the bottle mouth with a cotton plug, treat at 30°C, 200 rpm for 15 min, and collect the supernatant after the solution is centrifuged. Repeat the adsorption and calculate the ads...

Embodiment 2

[0051] Heat and boil Pichia pastoris with 0.1mol / L NaOH solution for 15 minutes, centrifuge at 1000-3000rpm, collect the bacteria, put them into an oven for drying at 105°C, and grind them into powder.

[0052] Take 100ml of actual industrial wastewater solution (the contents of chromium, nickel, copper, silver and molybdenum are 0.9 mg / L, 1.1 mg / L, 0.8 mg / L, 1.3 mg / L, 1.9 mg / L, pH=1.43) in the cone In the conical flask, add 0.1g, 0.2g, 0.3g, 0.4g, 0.5g of the bacterial adsorbent powder collected by the above method into the conical flask respectively, plug the bottle mouth with a cotton plug, and store at 30°C, 200 Rpm treatment for 30min to calculate the adsorption rate.

[0053] Pichia kurdori treated with NaOH has the highest adsorption capacity of heavy metals in industrial wastewater when its adsorption concentration is 1g / L, and the adsorption rates of heavy metals chromium, nickel, copper, silver and molybdenum on the treated biosorbent are 94% and 96% respectively , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com