Organic waste gas high-temperature pyrolysis device

An organic waste gas, high temperature pyrolysis technology, applied in gas treatment, membrane technology, dispersed particle separation and other directions, can solve the problems of high energy consumption, high cost, poor practicability, etc., to achieve low energy consumption, high work efficiency, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

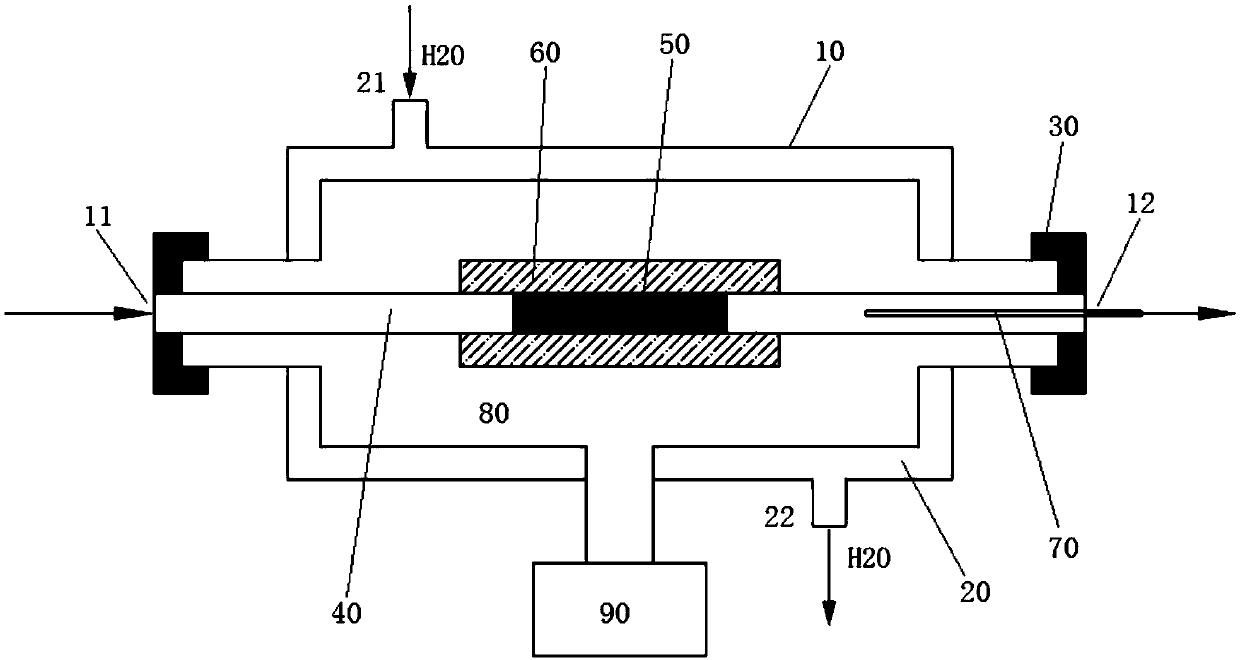

[0034] Such as figure 1Shown is a high-temperature pyrolysis device for organic waste gas in a preferred embodiment of the present invention, including an outer casing 10 , a quartz tube 40 , a wave-absorbing and heating zinc oxide honeycomb ceramic 50 and a magnetron 90 . The shell box 10 is provided with an organic waste gas inlet 11 and an organic waste gas outlet 12; the quartz tube 40 is installed in the shell box 10, one end of the quartz tube 40 is installed at the organic waste gas inlet 11, and the other end is installed at the organic waste gas There are 12 air outlets. The zinc oxide honeycomb ceramic 50 is filled inside the quartz tube 40 to form a microwave high-temperature reaction bed; the magnetron 90 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com