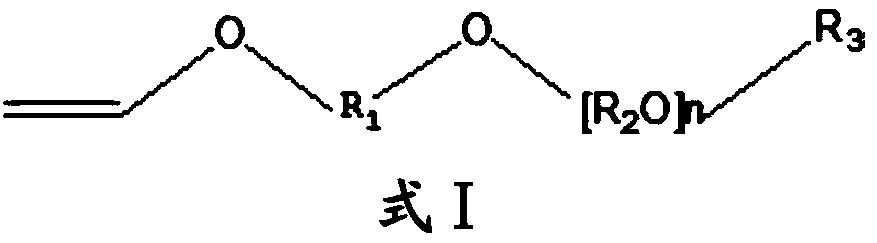

Polyether macromonomer, preparation method thereof and polycarboxylate superplasticizer prepared from polyether macromonomer

A technology of polyether macromonomer and water reducer, which is applied in the field of polyether macromonomer and its preparation, polycarboxylate water reducer and water reducer, and can solve problems such as high viscosity of concrete and concrete pipe plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

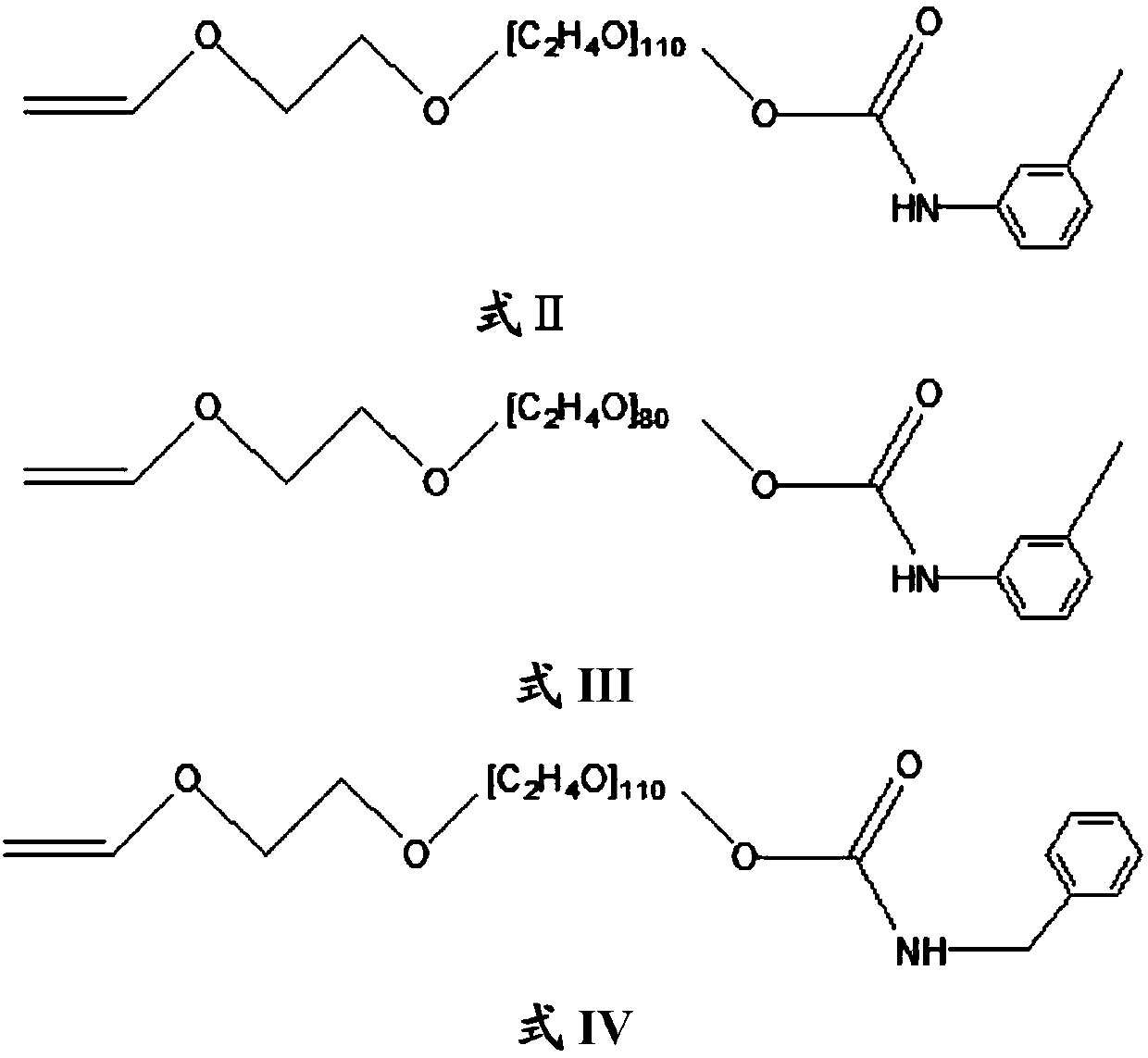

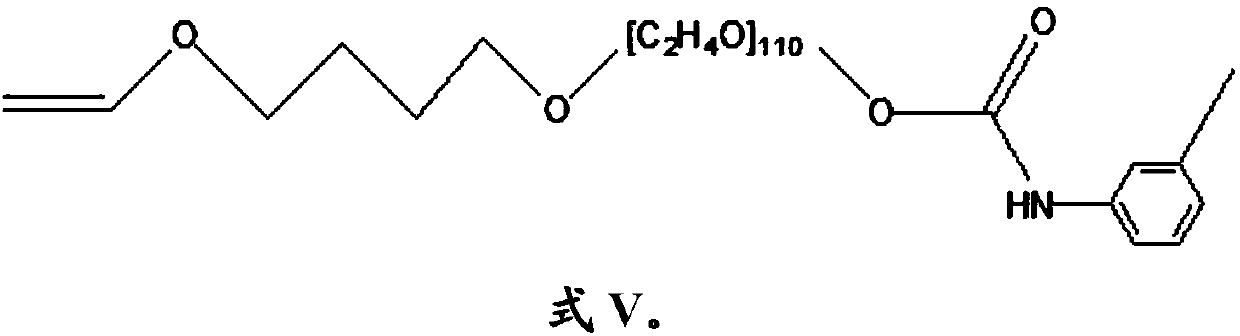

Embodiment 1

[0069] Under the protection of an inert gas, mix 10 parts by weight of the raw material alcohol 2-ethyleneoxyethanol and a stage of catalyst KOH at a temperature of 105 ° C, and then add 50 parts by weight of the first part of ethylene oxide under a pressure of 0.1-0.4 MPa. Mature the first reaction mixture at a temperature of 105°C to obtain an intermediate product; under an inert gas atmosphere, mix the second-stage catalyst KOH and the intermediate at a temperature of 110°C, and add the second part at a pressure of 0.1-0.4MPa 100 parts by weight of ethylene oxide, matured at a temperature of 115°C until the pressure no longer drops; take 240 parts by weight of the unsaturated ether sample and cool it down to 70°C, and test that the moisture content is lower than 0.3%. Slowly add 6.07 parts by weight of m-toluene isocyanate at a medium and uniform speed, control the reaction temperature at about 70°C, add dropwise for 60 minutes, keep warm for 3 hours after dropping, and vacu...

Embodiment 2

[0073] Under the protection of an inert gas, mix 10 parts by weight of the raw material alcohol 2-ethyleneoxyethanol with a catalyst KOH at a temperature of 105 ° C, and then add the first part of 50 parts by weight of ethylene oxide under a pressure of 0.1-0.4 MPa. Mature the first reaction mixture at a temperature of 105°C to obtain an intermediate product; under an inert gas atmosphere, mix the second-stage catalyst KOH and the intermediate at a temperature of 110°C, and add the second part at a pressure of 0.1-0.4MPa 80 parts by weight of ethylene oxide, aged at a temperature of 115 ° C until the pressure no longer drops; take 240 parts by weight of the unsaturated ether sample and cool it down to 70 ° C, and test that the moisture content is lower than 0.3%. Slowly add 6.87 parts by weight of m-toluene isocyanate at a medium and uniform speed, control the reaction temperature at about 70°C, add dropwise for 60 minutes, keep warm for 3 hours after dropping, and vacuumize an...

Embodiment 3

[0077]Under the protection of an inert gas, mix 10 parts by weight of raw material alcohol 2-ethyleneoxyethanol and a catalyst NaOH at a temperature of 105 ° C, and then add 50 parts by weight of the first part of ethylene oxide under a pressure of 0.1-0.4 MPa, The first reaction mixture is matured at a temperature of ℃ to obtain an intermediate product; under an inert gas atmosphere, the second-stage catalyst NaOH and the intermediate are mixed at a temperature of 110°C, and the second part of the ring is added under a pressure of 0.1-0.4MPa 100 parts by weight of oxyethane, aged at a temperature of 115 ° C until the pressure no longer drops; take 240 parts by weight of the unsaturated ether sample and cool it down to 70 ° C, and test that the moisture content is lower than 0.3%, then pour it into the reactor under the protection of nitrogen. Slowly add 6.07 parts by weight of benzyl isocyanate at a uniform speed, control the reaction temperature at about 70°C, add dropwise fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com