Novel environment-friendly plate and producing method thereof

A production method and board technology, applied in the field of new environmental protection board and its production, can solve the problems of unfavorable resource sustainable development and environmental protection, occupying land, endangering the environment, etc., achieve high environmental efficiency and economic benefits, and mild conditions , limited effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

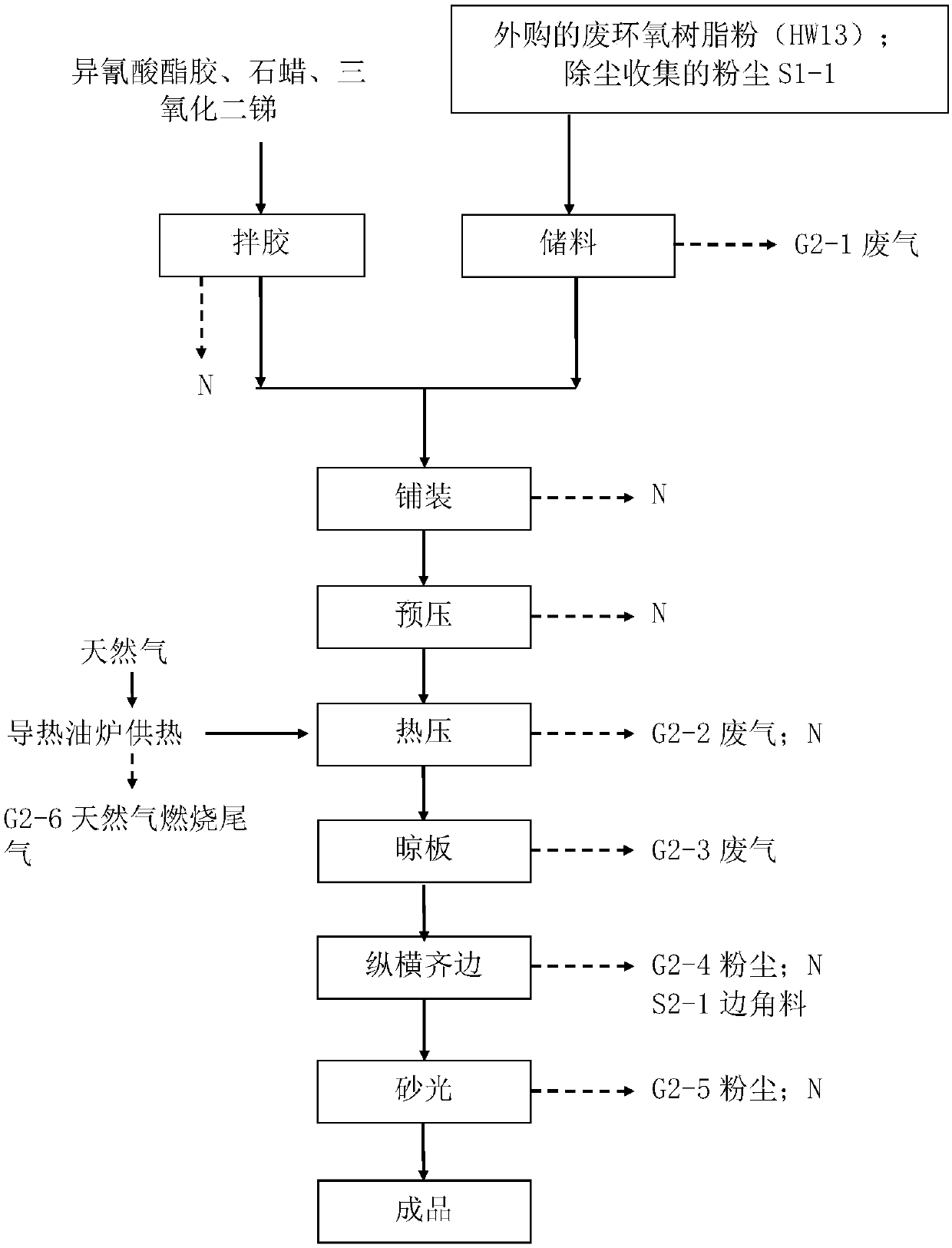

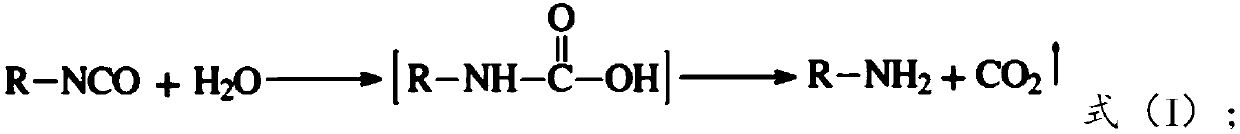

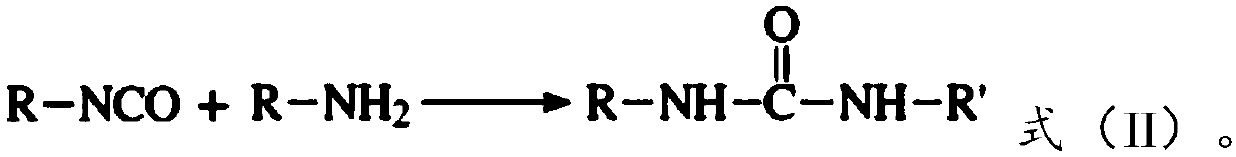

[0063] (1) Mix the isocyanate glue, paraffin wax and antimony trioxide with a mass ratio of 93:3:4 at room temperature under airtight conditions to obtain an adhesive; then mix 10 parts by weight of waste epoxy resin powder with 0.84 Adhesives in parts by weight are mixed and paved at room temperature, and then the paved materials are transported to the pre-pressing machine through the conveyor belt for pre-pressing. The pre-pressing pressure is 200kg / m 2 , the temperature is 25°C; then the pre-pressed material is transported to the hot press through a closed pipeline for hot pressing, and the pressure of the hot pressing is 55kg / m 2 ~65kg / m 2 , and the temperature is 170° C. to 190° C. to obtain a composite plate.

[0064] (2) The composite sheet material that step (1) is obtained is left standstill 10min at normal temperature on the air-drying machine, then uses the sawing machine to saw the composite sheet material after air-drying board to the size required by specificati...

Embodiment 2

[0067] (1) Mix the isocyanate glue, paraffin wax and antimony trioxide with a mass ratio of 91:4:5 at room temperature under airtight conditions to obtain an adhesive; then mix 10 parts by weight of waste epoxy resin powder with 0.84 Adhesives in parts by weight are mixed and paved at room temperature, and then the paved materials are transported to the pre-pressing machine through the conveyor belt for pre-pressing. The pre-pressing pressure is 200kg / m 2 , the temperature is 25°C; then the pre-pressed material is transported to the hot press through a closed pipeline for hot pressing, and the pressure of the hot pressing is 85kg / m 2 ~95kg / m 2 , and the temperature is 140° C. to 160° C. to obtain a composite plate.

[0068] (2) The composite sheet material that step (1) is obtained is left standstill 8min at normal temperature on the air-drying machine, then uses the sawing machine to saw the composite sheet material after air-drying board to the size required by specificatio...

Embodiment 3

[0071] (1) Mix the isocyanate glue, paraffin wax and antimony trioxide with a mass ratio of 93:3:4 at room temperature under airtight conditions to obtain an adhesive; then mix 10 parts by weight of waste epoxy resin powder with 0.84 Adhesives in parts by weight are mixed and paved at room temperature, and then the paved materials are transported to the pre-pressing machine through the conveyor belt for pre-pressing. The pre-pressing pressure is 200kg / m 2 , the temperature is 25°C; then the pre-pressed material is transported to the hot press through a closed pipeline for hot pressing, and the pressure of the hot pressing is 70kg / m 2 ~80kg / m 2 , and the temperature is 155° C. to 175° C. to obtain a composite plate.

[0072] (2) The composite sheet obtained in step (1) is allowed to stand at room temperature for 9 minutes on the air-drying machine, then use a sawing machine to saw the composite sheet after air-drying to the size required by the specification, and obtain semi-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com