Hydrophilic soft finishing agent applied to polyester-cotton fabric material

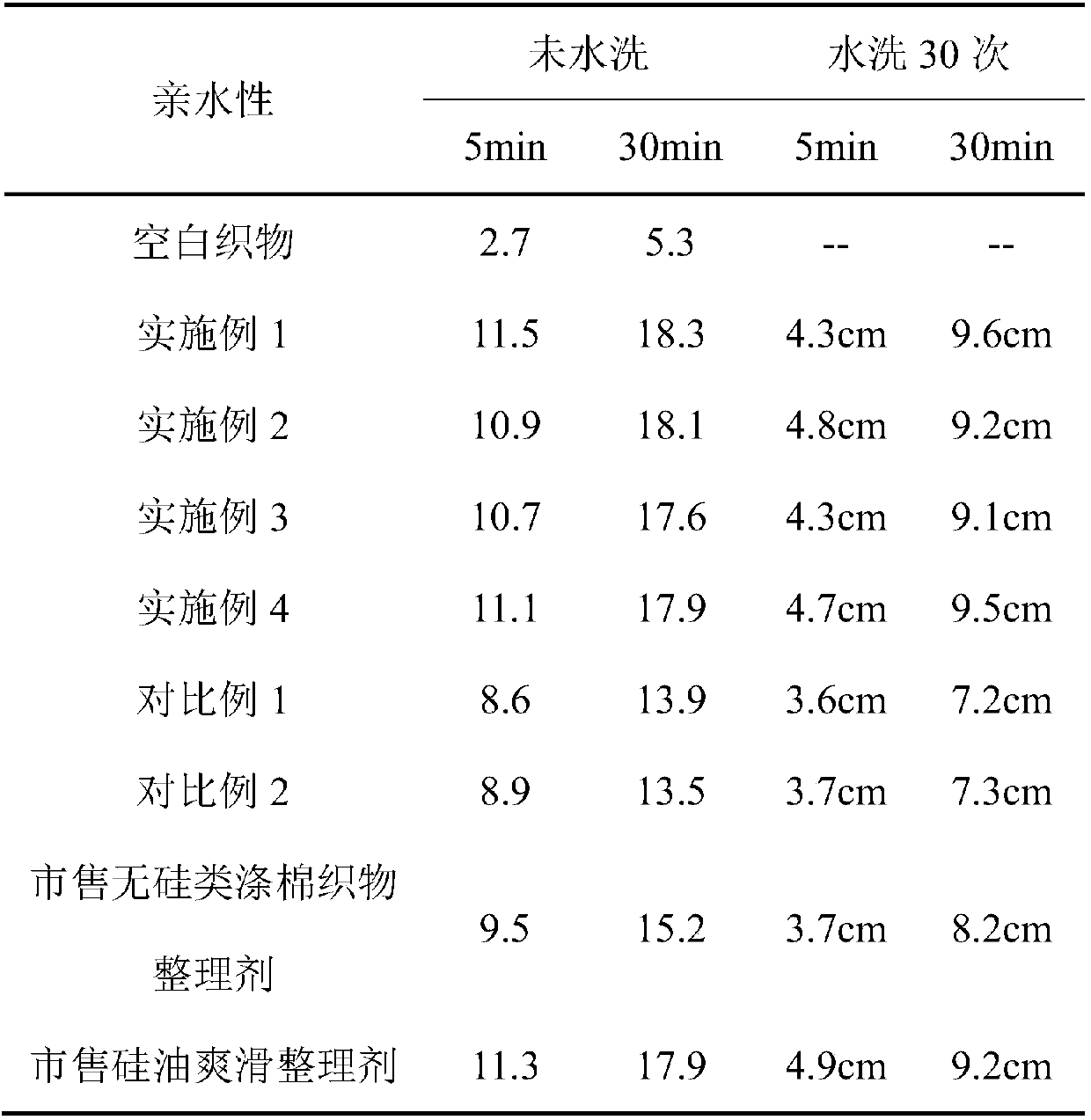

A technology of soft finishing agent and fabric materials, which is applied in fiber treatment, plant fiber, textiles and papermaking, etc. It can solve the problems of general finishing effect and achieve the effects of improving wearing performance, broadening the application range and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] This embodiment provides a kind of hydrophilic softening agent for polyester-cotton fabric material, and this finishing agent adopts following method to prepare:

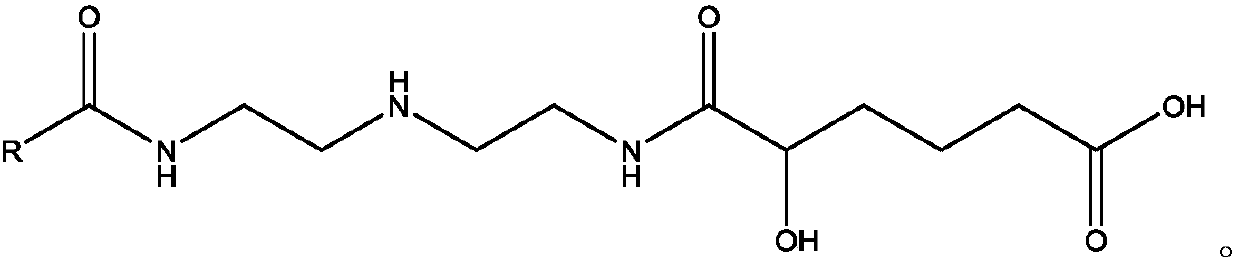

[0019] Step 1: Put 32.4g of 2-hydroxyethylene glycol, 20.2g of diethylenetriamine, 71g of stearic acid and 0.25g of concentrated sulfuric acid into a 250mL four-necked flask equipped with a thermometer, a stirring bar and reflux condensation, and ventilate with nitrogen. Acylate W was obtained after reacting at 190°C for a certain period of time.

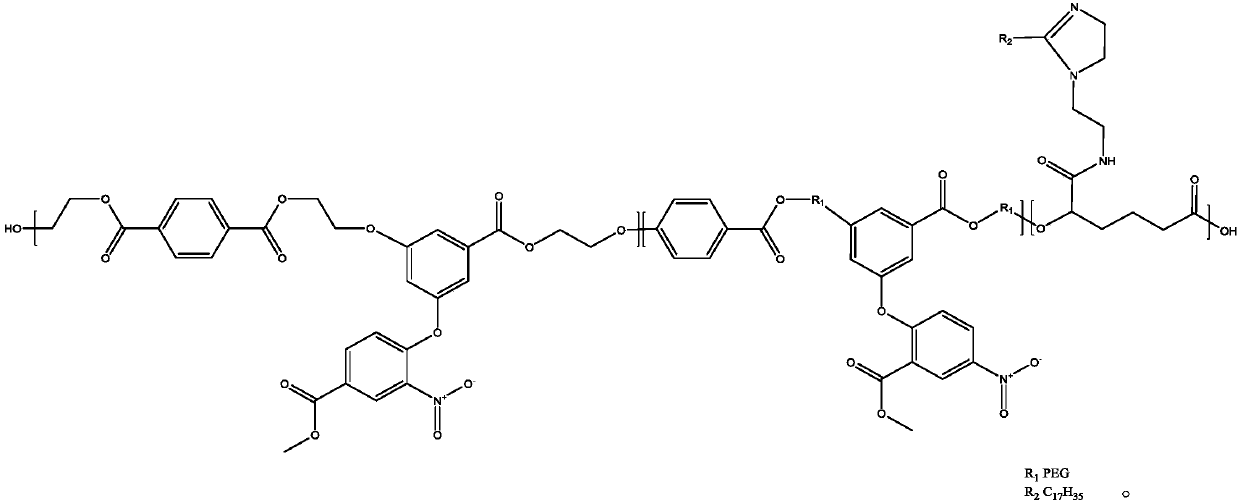

[0020] Step 2: 38g acylate W, 29.1g dimethyl terephthalate, 18.6g ethylene glycol, 71.25g polyethylene glycol (molecular weight is 1500), 20g5-{[3-(4-nitrophenyl )-3-oxopropanol base] amino} isophthalic acid dimethyl ester and 0.18g tetrabutyl titanate are dropped into the 250mL four-necked flask equipped with thermometer, stirring bar, nitrogen protection and reflux condensation, and the temperature is raised to 180 ℃ for 3 hours, gradually raised the temperature...

Embodiment 2

[0022] This embodiment provides a kind of hydrophilic softening agent for polyester-cotton fabric material, and this finishing agent adopts following method to prepare:

[0023] Step 1: drop into 32.4g 2-hydroxyethylene glycol, 20.2g diethylenetriamine, 71g stearic acid and 0.25g benzenesulfonic acid in the 250mL four-necked flask that thermometer, stirring rod and reflux condensation are equipped with, nitrogen, The acylate W was obtained after reacting at 190°C for a certain period of time.

[0024] Step 2: 47.5g acylate W, 29.1g dimethyl terephthalate, 18.6g ethylene glycol, 90g polyethylene glycol (molecular weight is 2000), 20g5-{[3-(4-nitrophenyl )-3-oxopropanol base] amino} isophthalic acid dimethyl ester and 0.31g tetraisopropyl titanate are dropped into the 250mL four-neck flask equipped with thermometer, stirring bar, nitrogen protection and reflux condensation, and the temperature is raised to React at 180°C for 3 hours, gradually raise the temperature to 230°C, ke...

Embodiment 3

[0026] This embodiment provides a kind of hydrophilic softening agent for polyester-cotton fabric material, and this finishing agent adopts following method to prepare:

[0027] Step 1: drop into 40.5g 2-hydroxyethylene glycol, 25.25g diethylenetriamine, 71.0g stearic acid and 0.34g p-toluenesulfonic acid in the 250mL four-neck flask that thermometer, stirring rod and reflux condensation are housed, pass Nitrogen, after reacting at 190°C for a certain period of time, the acylate W was obtained.

[0028] Step 2: 57g acylate W, 29.1g dimethyl terephthalate, 18.6g ethylene glycol, 142.5g polyethylene glycol (molecular weight is 3000), 20g5-{[3-(4-nitrophenyl )-3-oxopropanol base] amino} isophthalic acid dimethyl ester and 0.4g tetrabutyl titanate are dropped into the 250mL four-neck flask equipped with thermometer, stirring bar, nitrogen protection and reflux condensation, and the temperature is raised to 180 ℃ for 3 hours, gradually raised the temperature to 230 ℃, kept the tem...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap