Oil-proof wrapping paper and preparation method thereof

A technology of wrapping paper and oil-proof paper, which is applied in the direction of wrapping paper, wrapping paper, packaging, etc., can solve the problems of oil-proof food wrapping paper not being environmentally friendly, high amount of oil-proof agent used, and low product strength, so as to improve product grade and Effect of adding value, improving surface oil repellency, and improving internal oil repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

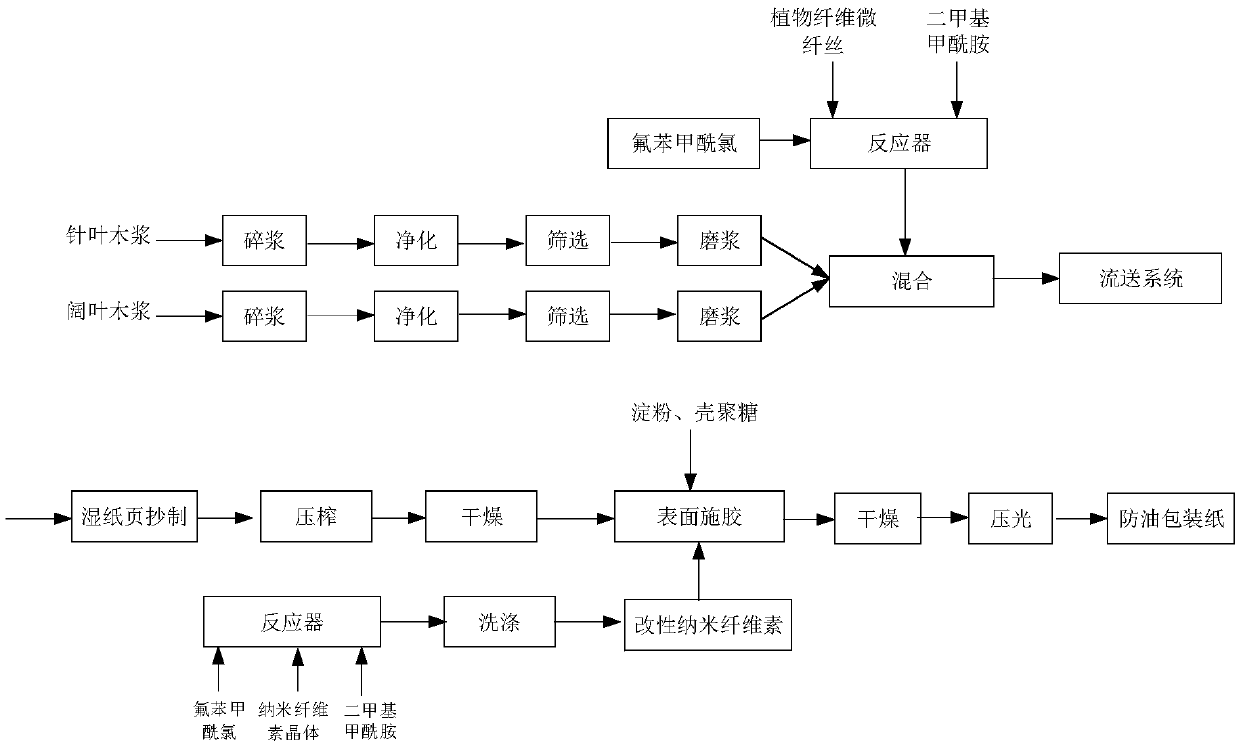

Method used

Image

Examples

Embodiment 1

[0044] A kind of preparation method of oil-proof wrapping paper of the present embodiment, described method comprises the steps:

[0045] (1) Preparation of oil-resistant plant microfibrils

[0046] At room temperature, sequentially add 50kg of fluorobenzoyl chloride, 50kg of dimethylformamide, and 50kg of plant fiber microfibrils into the reactor, stir and mix evenly, heat to 70°C, and stir and react at 70°C for 2 hours; After the end, cool to room temperature, filter the product, remove excess solvent, then wash twice with dichloromethane, then wash twice with ethanol, take it out after washing, and dry at 60°C for 24 hours to obtain oil-resistant plant microfibers silk; wherein: the diameter of the plant fiber microfibril is 5-10um, and the length is 200-400um.

[0047] (2) the preparation method of oil-proof (modified) nano-cellulose, described method comprises the steps:

[0048] At room temperature, sequentially add 1000g of fluorobenzoyl chloride, 750g of dimethylform...

Embodiment 2

[0057] A kind of preparation method of oil-proof wrapping paper of the present embodiment, described method comprises the steps:

[0058] (1) Preparation of oil-resistant plant microfibrils

[0059] At room temperature, sequentially add 25kg of fluorobenzoyl chloride, 50kg of dimethylformamide, and 50kg of plant fiber microfibrils into the reactor, stir and mix evenly, heat to 80°C, and stir and react at 80°C for 1 hour; After the end, cool to room temperature, filter the product, remove excess solvent, then wash 4 times with dichloromethane, then wash 4 times with ethanol, take it out after washing, and dry at 60°C for 24 hours to obtain oil-resistant plant microfibers silk; wherein: the diameter of the plant fiber microfibril is 5-10um, and the length is 200-400um.

[0060] (2) Preparation of oil-resistant nanocellulose

[0061] At room temperature, sequentially add 500g of fluorobenzoyl chloride, 500g of dimethylformamide, and 250g of nanocellulose crystals into the react...

Embodiment 3

[0070] A kind of preparation method of oil-proof wrapping paper of the present embodiment, described method comprises the steps:

[0071] (1) Preparation of oil-resistant plant microfibrils

[0072] At room temperature, sequentially add 50kg of fluorobenzoyl chloride, 100kg of dimethylformamide, and 50kg of plant fiber microfibrils into the reactor, stir and mix evenly, heat to 75°C, and stir and react at 75°C for 1.5h; After the reaction, cool to room temperature, filter the product, remove excess solvent, then wash 5 times with dichloromethane, then wash 5 times with ethanol, take out and dry at 60°C for 24 hours to obtain oil-resistant plant microfibrils; : the diameter of the plant fiber microfibril is 5-10um, and the length is 200-400um.

[0073] (2) Preparation of oil-resistant nanocellulose

[0074] At room temperature, sequentially add 750g of fluorobenzoyl chloride, 500g of dimethylformamide, and 250g of nanocellulose crystals into the reactor, stir and mix evenly, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com