A method for drying paint residue

A technology for paint waste residue and drying method, which is applied in the fields of garbage drying, drying solid materials, and drying goods processing, etc., can solve the problems of difficulty in large-scale promotion, difficult transportation, and low weight reduction rate, and achieves reduction of unit drying energy consumption, Significant economic benefits and the effect of increasing the reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

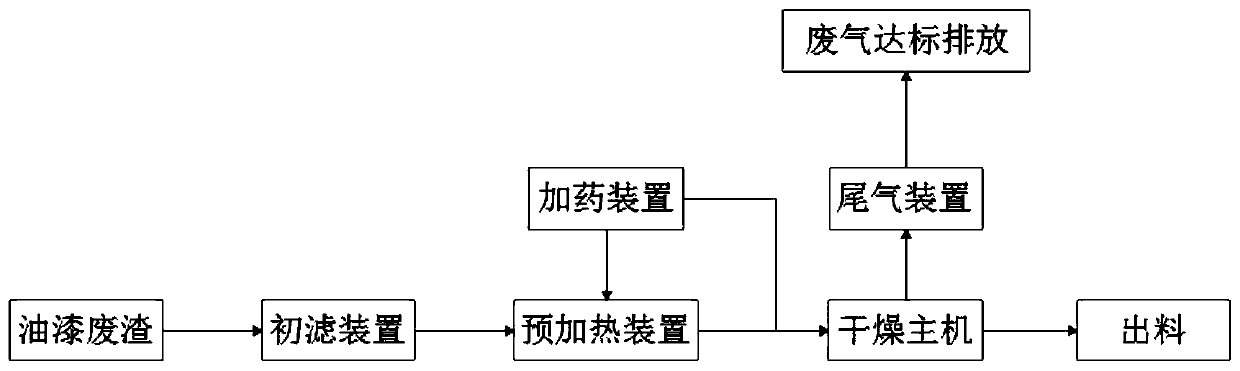

[0026] Such as figure 1 As shown, a paint waste drying method includes a paint waste drying system, the paint waste drying system includes a primary filter device, a preheating device, a dosing device, a drying host and an exhaust gas treatment device, and the paint waste enters the primary filter device buffer and Pretreatment: The preheating device is respectively connected with the primary filter device, the dosing device and the drying host, and the drying host is connected with the tail gas treatment device through a vacuum pipeline.

[0027] The incoming material from the primary filtration device enters the feed hopper of the pre-heating device, and the incoming material from the pre-heating device enters the drying host through the adapter. , The exhaust gas produced by the devolatization of the drying main engine is collected in an organized manner through the vacuum pipeline, and then enters the exhaust device through the pipeline under the suction of the vacuum pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com