Preparation method of cathode material coated with carbon in situ with carbon sulfide

A metal sulfide, in-situ coating technology, applied in negative electrodes, active material electrodes, battery electrodes, etc., can solve problems such as complex experimental methods, achieve simple preparation methods, great development potential and application prospects, and good electrochemical performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Mix ferrocene and S powder in a certain proportion.

[0028] (2) Put the mixed powder in a mortar and grind it to make it evenly mixed.

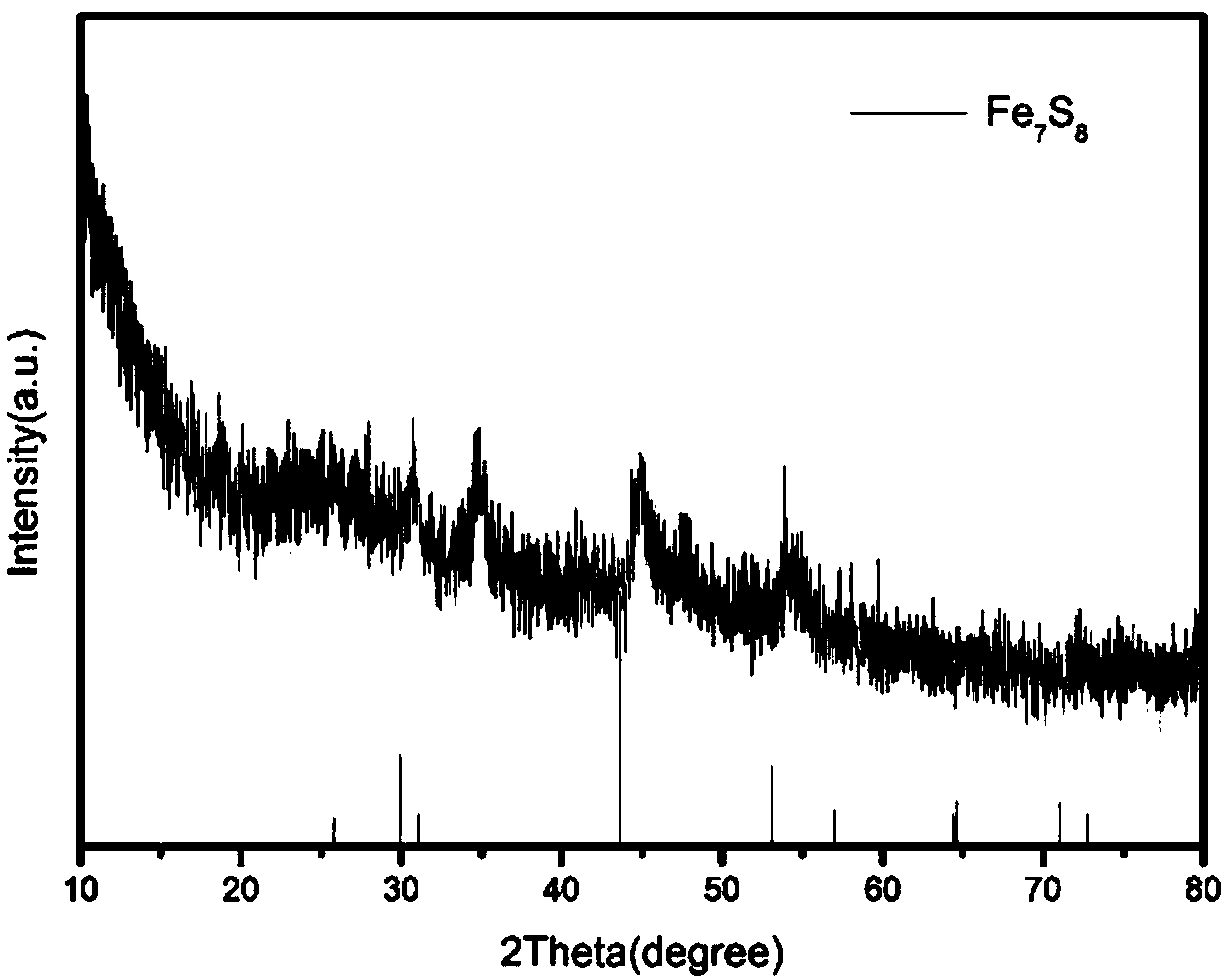

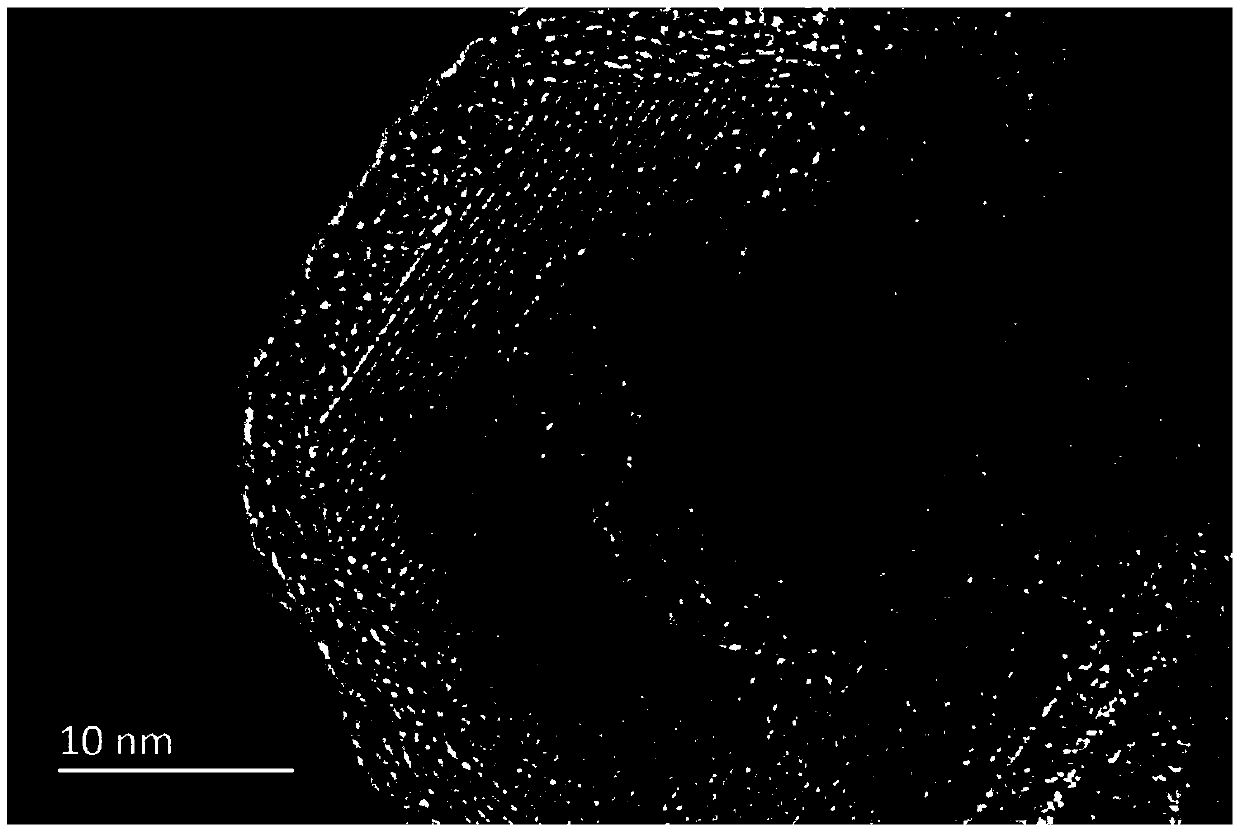

[0029] (3) Put the ground mixed powder in a porcelain boat, put it into an atmosphere furnace, perform high-temperature treatment, and lower it to room temperature to obtain FeSx@C anode material.

[0030] The above-mentioned preparation method is described in detail below:

[0031] The ratio of ferrocene to S in step 1 of the present invention is 1:6.

[0032] The high temperature treatment condition described in step 3 is: N 2 Atmosphere, the temperature was raised to a constant temperature of 650°C at a rate of 5°C / min, and the mixture powder was calcined for 3 hours during the constant temperature process.

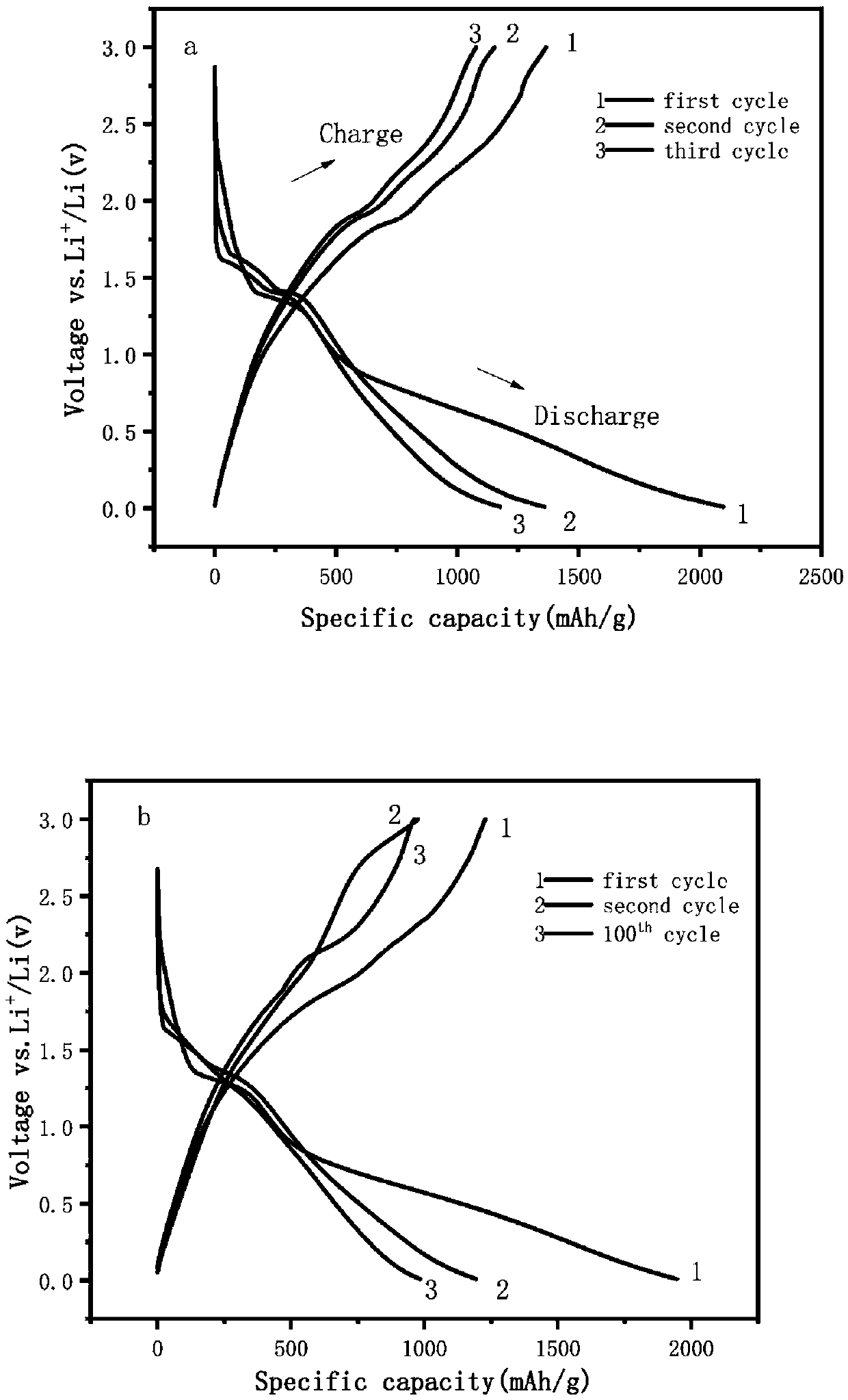

[0033] The FeSx@C material prepared in Example 1 is used as the negative electrode material, PVDF is used as the binder, and acetylene black is used as the conductive agent, and weighed according to a certain ratio (act...

Embodiment 2

[0035] (1) Mix ferrocene and S powder in a certain proportion.

[0036] (2) Put the mixed powder in a mortar and grind it to make it evenly mixed.

[0037] (3) Put the ground mixed powder in a porcelain boat, put it into an atmosphere furnace, perform high-temperature treatment, and lower it to room temperature to obtain FeSx@C anode material.

[0038] The above-mentioned preparation method is described in detail below:

[0039] The ratio of ferrocene to S in step 1 of the present invention is 1:4.

[0040] The high temperature treatment condition described in step 3 is: N 2 Atmosphere, the temperature was raised to a constant temperature of 650°C at a rate of 5°C / min, and the mixture powder was calcined for 3 hours during the constant temperature process.

[0041] The FeSx@C material prepared in Example 1 is used as the negative electrode material, PVDF is used as the binder, and acetylene black is used as the conductive agent, and weighed according to a certain ratio (activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com