Solid particulate mineral oil defoaming agent and preparation method thereof

A technology of solid particles and mineral oil, applied in the field of defoamer, can solve the problems of edge shrinkage, coating shrinkage, poor product stability, etc., and achieve good repeatability and controllability, simple process operation, and huge economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This example provides a solid particulate mineral oil defoamer 1 and its preparation method.

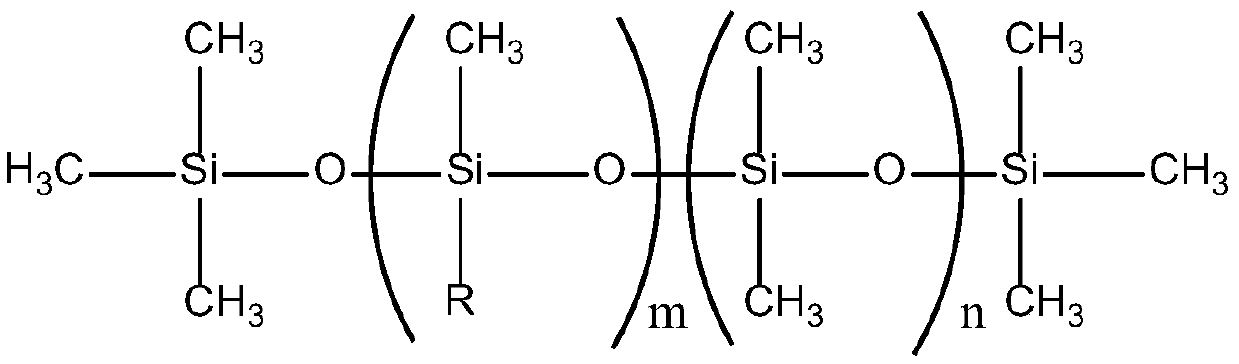

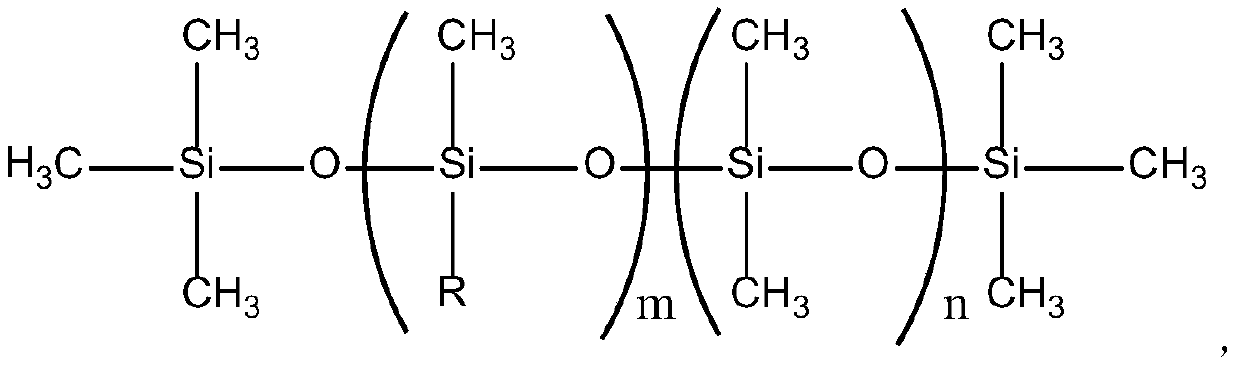

[0051] Described solid particle mineral oil defoamer is made up of following raw material by mass percent: industrial No. 5 white oil 87%, alkyl modified silicone oil (the number of carbon atoms in the group R is 8, m=70, n=560) 10%, hydrophobic fumed silica 1%, polyether (PPG5000) 1% and emulsifier (composed of Span80:Tween80 at a mass ratio of 5:1) 1%.

[0052] The preparation method is as follows:

[0053](1) Take 10 g of alkyl-modified silicone oil and 1 g of silazane-modified hydrophobic fumed silica at a stirring speed of 300 rpm, a temperature of 100° C., and a reaction time of 0.5 h to prepare a silicone paste.

[0054] (2) Add 87.0g industrial No. 5 white oil, 11.0g silicone paste, 1.0g PPG5000 and 1.0g emulsifier into the container, and react for 0.5h at a temperature of 60°C to obtain a mixture; After high-speed dispersion for 0.5 h, the solid particle mineral oil...

Embodiment 2

[0056] This embodiment provides a solid particulate mineral oil defoamer 2 and its preparation method.

[0057] Described solid particle mineral oil defoamer is made up of following raw material by mass percent: liquid paraffin 64%, alkyl modified silicone oil (the number of carbon atoms in the group R is 8, m=60, n=600 ) 23.5%, hydrophobic fumed silica 1.5%, polyether (PPG5000) 5% and emulsifier (compounded by Span80:Tween80 according to the mass ratio of 5:1) 6%.

[0058] (1) Take 24g of alkyl-modified silicone oil and 1g of silicone oil-modified hydrophobic fumed silica at a stirring speed of 300rpm, a reaction temperature of 110°C, and a reaction time of 1h to prepare a silicone paste.

[0059] (2) Add 64.0g of liquid paraffin, 25.0g of silicone paste, 5.0g of PPG5000 and 6.0g of emulsifier into the container, and react for 1.0h at a temperature of 80°C to obtain a mixture; h, obtaining the described solid particle mineral oil defoamer.

Embodiment 3

[0061] This embodiment provides a solid particulate mineral oil defoamer 3 and its preparation method.

[0062] Described solid particulate matter mineral oil defoamer is made up of following raw material by mass percent: industrial No. 32 white oil 86%, alkyl modified silicone oil (the number of carbon atoms in the group R is 12, m=70, n=560) 10%, hydrophobic fumed silica 1%, polyether (PPG5000) 0.5%, and emulsifier (composed of Span80:Tween80 in a mass ratio of 5:1) 2.5%.

[0063] (1) Take 10g of alkyl-modified silicone oil (the number of carbon atoms in the group R is 12) and 1g of silicone oil-modified hydrophobic fumed silica at a stirring speed of 300rpm and a temperature of 120°C. 2h, the silicone paste was prepared.

[0064] (2) Add 86.0g industrial No. 32 white oil, 11.0g silicone paste, 0.5g PPG5000 and 2.5g emulsifier into the container, and react for 0.5h at a temperature of 60°C to obtain a mixture; Disperse for 0.5h to obtain the solid particle mineral oil defo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com