Aromatic hydrocarbon methylation catalyst and a preparation method thereof

A methylation and catalyst technology, applied in the field of aromatic hydrocarbon methylation catalyst and its preparation, can solve the problems of low reaction activity, difficult preparation and poor stability of aromatic hydrocarbon methylation, and achieve the promotion of stability, fast diffusion rate and stable good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

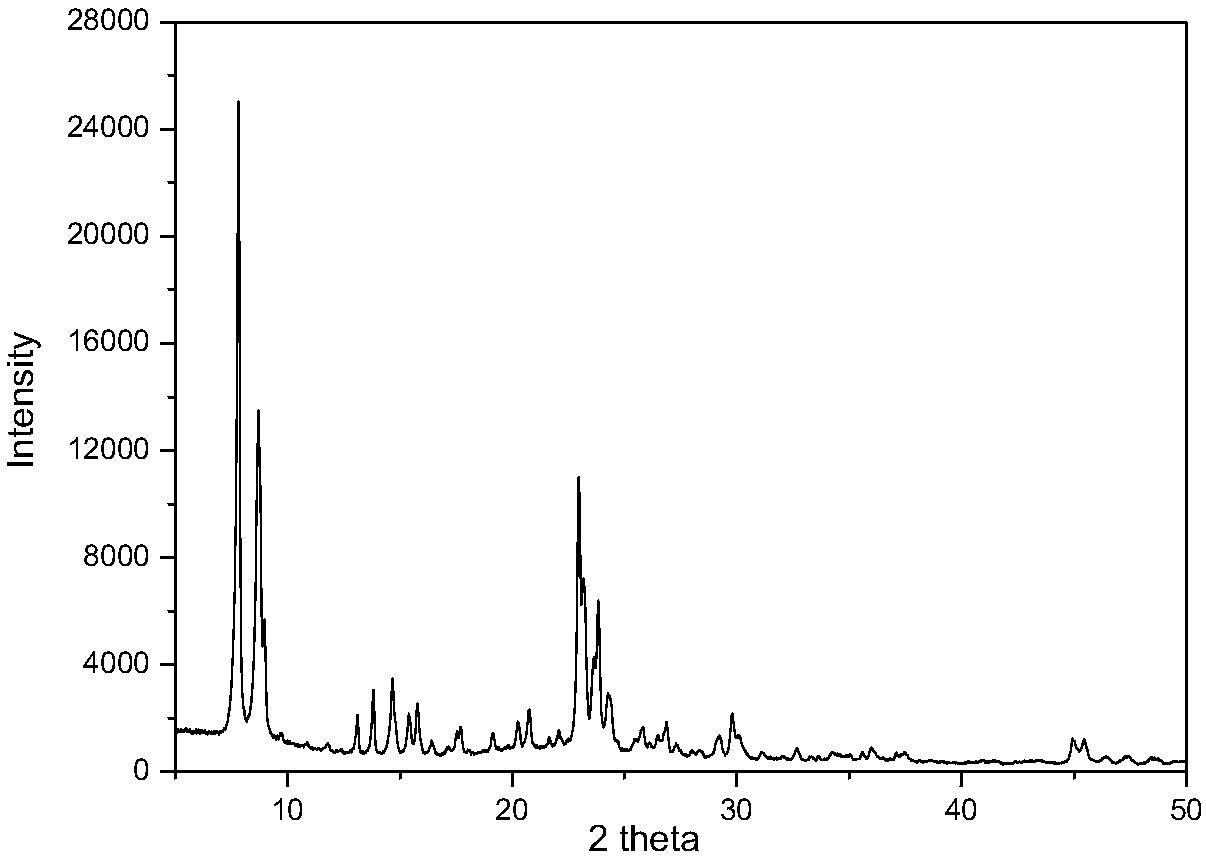

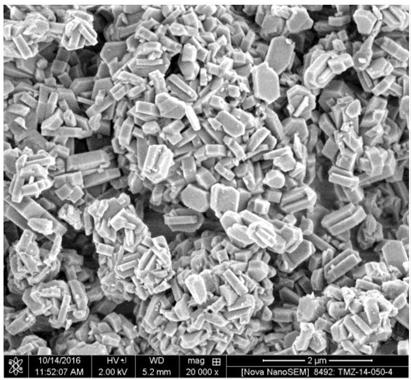

[0052] 2 grams of aluminum nitrate, 5 grams of ethylamine (M1) and 30 milliliters of water were stirred and dissolved to form solution A, 40 grams of tetraethyl orthosilicate and 50 grams of deionized water were mixed and stirred at room temperature for 5 hours to form solution B. Slowly add solution A, stir vigorously for 2 hours, add 1wt% ZSM-5 seed crystals and stir for 1 hour, add 15 grams of ammonia water (M2), then transfer the mixed system into a stainless steel crystallization kettle, and crystallize at 150°C for 72 hours. The XRD pattern of the obtained sample has the characteristic diffraction peaks of ZSM-5 zeolite molecular sieve, and the thickness of the flake molecular sieve in the SEM image is about 80nm. Product SiO 2 / Al 2 o 3 The molar ratio is 63, Na + The content is 0.02%, and the molecular sieve yield is 96%.

[0053] Weigh 20 grams of the above-mentioned molecular sieves, 17 grams of alumina, 1 milliliter of concentrated nitric acid, 2.5 grams of ammo...

Embodiment 2

[0056] 1.5 grams of aluminum sulfate, 2 grams of diethylamine (M1) and 30 milliliters of water were stirred and dissolved to form solution A, 50 grams of silica sol (40%) and 10 grams of deionized water were mixed and stirred at room temperature for 0.5 hours to form solution B. Slowly add B into solution A, stir vigorously for 2 hours, add 2wt% ZSM-5 seed crystals and stir for 1 hour, add 5 g of ethylamine (M2) solution, and move the mixed system into a stainless steel crystallization kettle, crystallize at 170 ° C for 24 hours. The XRD pattern of the obtained sample has the characteristic diffraction peaks of ZSM-5 zeolite molecular sieve, and the thickness of the flake molecular sieve in the SEM image is about 50 nm. Product SiO 2 / Al 2 o 3 The molar ratio is 147, Na + The content is 0.01%, and the molecular sieve yield is 98%

[0057] Weigh 20 grams of the above-mentioned molecular sieves, 6 grams of alumina, 0.5 milliliters of concentrated nitric acid, 1.5 grams of m...

Embodiment 3

[0060] 5 grams of aluminum nitrate, 2 grams of ethylenediamine (M1) and 30 grams of deionized water were stirred and dissolved to form solution A, 40 grams of white carbon black was added to 50 grams of water and continued to stir to obtain solution B, and solution B was slowly added to solution A , Stir vigorously for 2 hours, add 0.5wt% ZSM-5 seed crystals and stir for 1 hour, finally add 8 grams of ammonia water (M2) and mix evenly, transfer to a stainless steel crystallization kettle, and crystallize at 130°C for 72 hours. The XRD spectrum of the obtained sample has the characteristic diffraction peaks of ZSM-5 zeolite molecular sieve, and the thickness of the flake molecular sieve in the SEM image is about 30 nm. Product SiO 2 / Al 2 o 3 The molar ratio is 98, Na + The content is 0.01%, and the molecular sieve yield is 97%

[0061] Weigh 20 grams of the above-mentioned molecular sieves, 15 grams of silica sol (40%), 2 grams of ammonium molybdate, 1 gram of turnip powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com