Methyl benzoate preparation method

A technology of methyl benzoate and benzoic acid, which is applied in the field of preparation of methyl benzoate, can solve the problems of frequent regeneration, high price, complex preparation process of solid catalyst, etc., achieve less by-products, high recycling performance, and optimize ester chemical reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

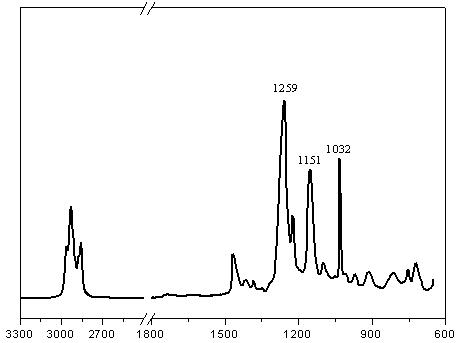

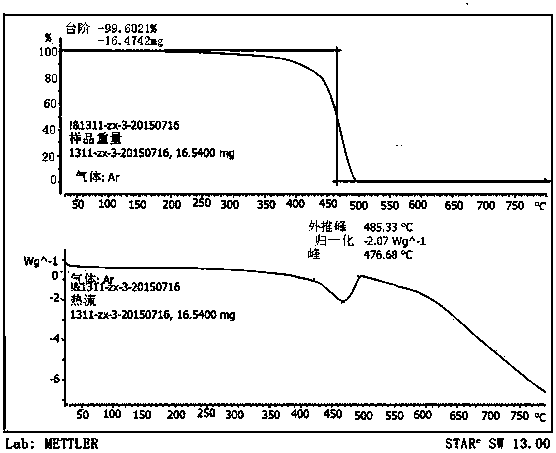

Image

Examples

Embodiment 1

[0015] Embodiment 1 Preparation of quaternary phosphonium salt ionic liquid catalyst

[0016] The quaternary phosphonium salt ionic liquid used in the present invention is prepared according to the following steps: under ion exchange reaction conditions, the first quaternary phosphonium salt is contacted with a protonic acid to obtain a contact product. Wherein, the general formula of the first quaternary phosphonium salt is [Bu 3 PR] + Z - , R is C 6 -C 16 straight-chain or branched-chain alkyl, and Z is halogen. The general formula of a protic acid is H + x - , X - selected from p-C 7 h 7 SO 3 - 、CF 3 SO 3 - 、HSO 4 - and H 2 PO 4 - at least one of the The first quaternary phosphonium salt can be obtained commercially, and can also be prepared by methods well known to those skilled in the art. The first quaternary phosphonium salt includes but is not limited to [Bu 3 PC 12 h 25 ] + Cl - 、[Bu 3 PC 14 h 29 ] + C - 、[Bu 3 PC 10 h 21 ] + Cl - a...

Embodiment 2

[0019] The preparation of embodiment 2 methyl benzoate

[0020] ⑴Esterification reaction: add 61.73 benzoic acid, 80.96g methanol and 7.14g quaternary phosphonium salt ionic liquid in 500ml autoclave (the molar ratio of benzoic acid and methanol is 1:5, quaternary phosphonium salt ionic liquid 5% (weight) of the weight, the quaternary phosphonium salt ionic liquid is [Bu 3 PC 14 h 29 ] + [p-C 7 h 7 SO 3 ] - . Start stirring (350 rpm), then start heating, bring the temperature in the autoclave to 130°C, start timing, and react for 3 hours;

[0021] (2) Separation and purification of methyl benzoate: ① After the reaction, turn off the heating power supply, and after cooling down to room temperature, stop stirring, transfer the reaction solution to a distillation device (normal pressure), heat up, and distill to evaporate unreacted methanol. ② After no methanol is evaporated, turn off the heating, lower the temperature, change the atmospheric distillation device to a red...

Embodiment 3

[0024] The preparation of embodiment 3 methyl benzoate

[0025] (1) Esterification reaction: Add 54.05 g of benzoic acid, 70.88 g of methanol and 24.99 g of quaternary phosphonium salt ionic liquid in a 500ml autoclave (the molar ratio of benzoic acid and methanol is 1:5, and the quaternary phosphonium salt ionic liquid catalyst is the total reactant 20% (weight) of the weight, the quaternary phosphonium salt ionic liquid is [Bu 3 PC14 h 29 ] + [p-C 7 h 7 SO 3 ] - . Start stirring (350 rpm), then start heating, bring the temperature in the autoclave to 130°C, start timing, and react for 3 hours;

[0026] (2) separation and purification of methyl benzoate: method of operation and steps are with embodiment 2, collect cut 44.37g altogether;

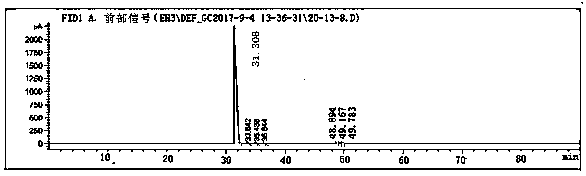

[0027] (3) Analysis and detection: the cut obtained by distillation under reduced pressure, i.e. methyl benzoate sampling is carried out by gas chromatography, with a purity of 99.6%;

[0028] The calculated yield of methyl benzoate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com