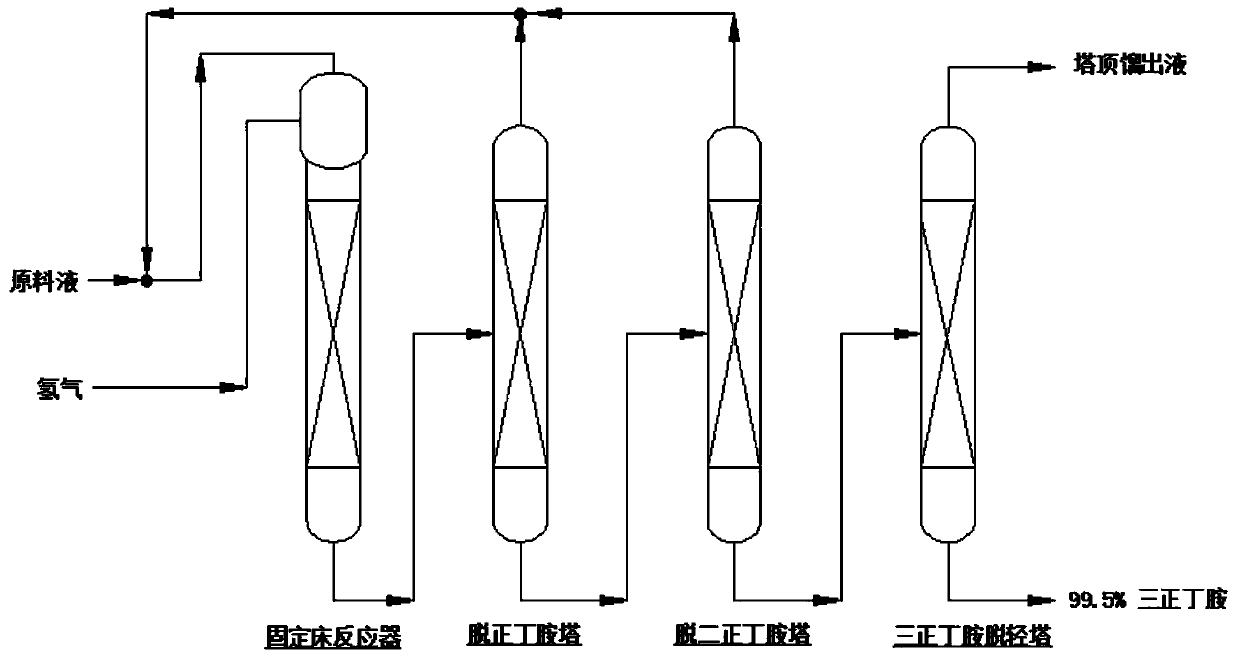

Device and method for producing tri-n-butylamine by extractive rectification heavy component removal

A tri-n-butylamine, extraction and rectification technology, applied in the direction of amino compound purification/separation, organic chemistry, etc., can solve the problem of increased energy consumption of the device, the inability to discharge N-butyl butyramide, and the inability to N-butyl butanamide Eliminate problems such as the production system to achieve the effect of reducing the amount of processing and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

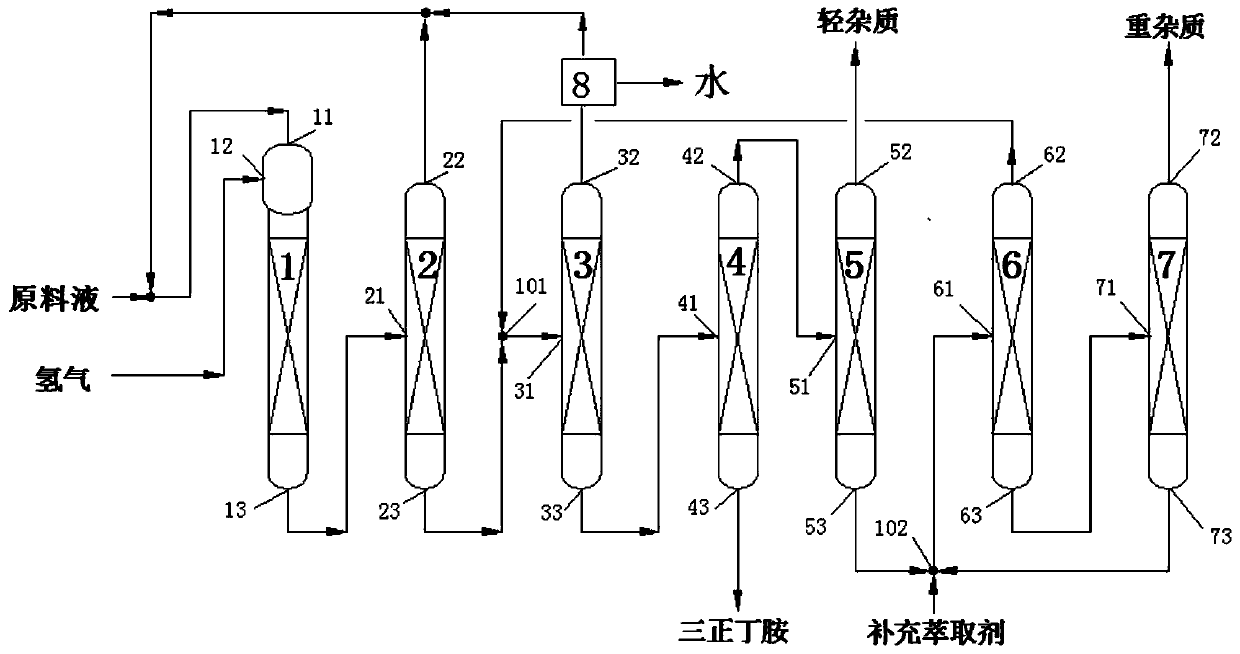

[0050] Example 1, a kind of tri-n-butylamine production device of extracting and rectifying deweighting, consists of fixed bed reactor 1, removing n-butylamine tower 2, removing di-n-butylamine tower 3, tri-n-butylamine removing tower 4, molecule Distillation tower 5, extractive rectification tower 6 and extraction agent regeneration tower 7 are formed;

[0051] The upper part of the fixed-bed reactor 1 is a vaporization chamber, and the lower part is a fixed-bed reaction section, and the vaporization chamber is respectively provided with a raw material liquid inlet 11 and a hydrogen inlet 12;

[0052] The n-butylamine removal tower 2, the di-n-butylamine removal tower 3, the tri-n-butylamine light removal tower 4, the extractive distillation tower 6 and the extraction agent regeneration tower 7 are all rectification towers, and are all provided with a feed inlet, a tower top Distillate port and tower bottom liquid outlet; details are as follows:

[0053] The de-n-butylamine ...

Embodiment 1

[0069] Embodiment 1, using the device described in the above example 1 for the production method of tri-n-butylamine for extracting, rectifying and deweighting, the composition of the mixed raw material liquid is: the concentration of n-butanol is 15%, and the concentration of n-butylamine is 30% , the concentration of di-n-butylamine is 30%, the concentration of N-isobutyl-N, N-di-n-butylamine IDA is 0.1%, the concentration of N-butyl butyramide BBA is 0.1%, and the rest are water; Do the following steps:

[0070] The mixed raw material liquid enters the vaporization chamber of the fixed-bed reactor 1 from the raw material liquid inlet 11, and the temperature in the vaporization chamber is 250°C, so that the above-mentioned raw material liquid is vaporized into a gas; at the same time, hydrogen enters the fixed-bed reactor 1 through the hydrogen gas inlet 12 The vaporization chamber of the above-mentioned vaporized raw material liquid and hydrogen are mixed in the vaporizatio...

Embodiment 2

[0079] Embodiment 2, with respect to embodiment 1, change following parameter:

[0080] The composition of the raw material liquid is: the concentration of n-butanol is 18%, the concentration of n-butylamine is 28%, the concentration of di-n-butylamine is 32%, N-isobutyl-N,N-di-n-butylamine IDA The concentration is 0.15%, the concentration of N-butylbutyramide BBA is 0.08%, and the rest is water;

[0081] Utilize hydrogen to regulate the internal pressure of the fixed-bed reaction section of fixed-bed reactor 1 to 1.1MPa, fixed-bed reaction section arranges the catalyst after activation (the active component in this catalyst is nickel, and carrier is 4A molecular sieve, and active component content is 27%, Activation treatment by hydrogen reduction before use); the reaction temperature in the fixed-bed reactor 1 is controlled at 190°C, and the volume space velocity of the raw material liquid is 0.09h -1 .

[0082] In the n-butylamine removal tower 2, setting tower still temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com