Thermoplastic nylon composite insulating material and preparation method thereof

A composite insulation and thermoplastic technology, used in the preparation of thermoplastic nylon composite insulation materials, the field of thermoplastic nylon composite insulation materials, to achieve the effect of miniaturization and strong electrical insulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

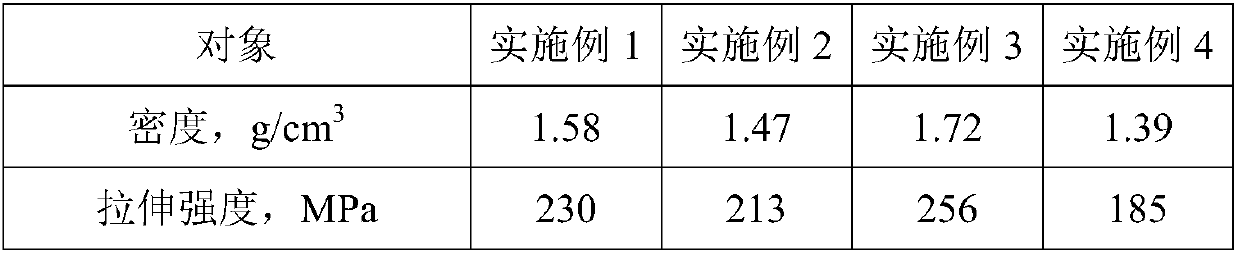

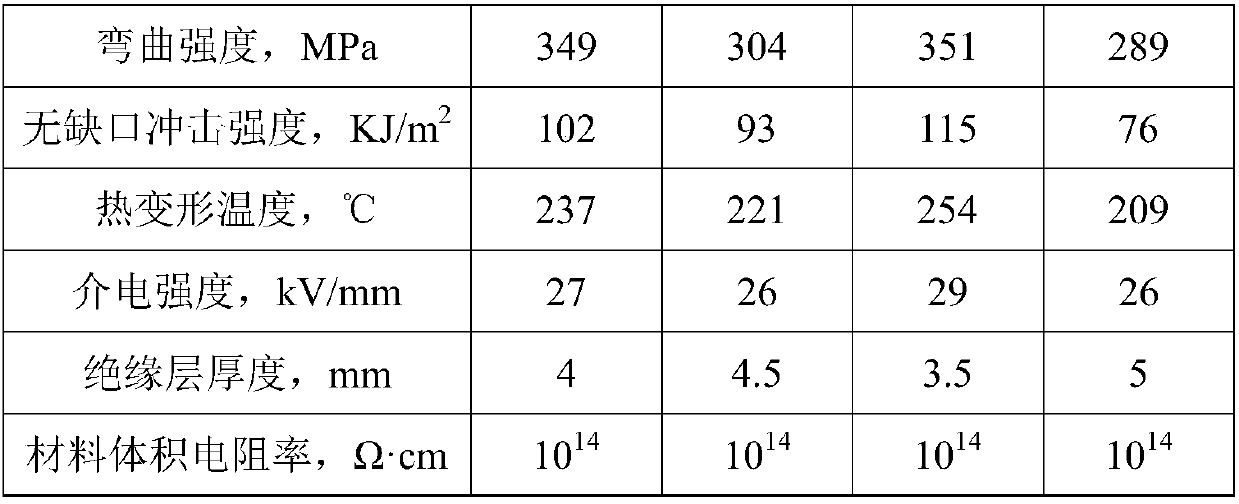

Embodiment 1

[0031] The thermoplastic nylon composite insulating material of this embodiment is composed of nano-montmorillonite and the following components by weight: 42.25 parts of nylon 66 resin, 50 parts of glass fiber, 0.25 part of antioxidant 1098, toughening agent SEBS (styrene- Ethylene-hydrogenated butadiene-styrene block copolymer) 4 parts; the mass percentage content of the nano-montmorillonite in the composite material is 3.5%. The glass fiber is an alkali-free short fiber with a length of 3-6 mm and a diameter of 9-13 μm; the glass fiber is surface-treated with a silane coupling agent in advance.

[0032] The preparation method of the thermoplastic nylon composite insulating material in this embodiment is to mix nano-montmorillonite, nylon 66 resin, antioxidant and toughening agent according to the formula to prepare a premix, and feed the premix and glass fiber into the twin screw The extruder extrudes and granulates, that is, the temperature of the feeding section of the tw...

Embodiment 2

[0034] The thermoplastic nylon composite insulating material of this embodiment is composed of nano-montmorillonite and the following components by weight: 54.2 parts of nylon 66 resin, 40 parts of glass fiber, 0.8 parts of antioxidant 1010, toughening agent SBS (styrene- Butadiene-styrene block copolymer) 3 parts; the mass percentage content of the nano-montmorillonite in the composite material is 2.0%. The glass fiber is an alkali-free short fiber with a length of 3-6 mm and a diameter of 9-13 μm; the glass fiber is surface-treated with a silane coupling agent in advance.

[0035] The preparation method of the thermoplastic nylon composite insulating material in this embodiment is to mix nano-montmorillonite, nylon 66 resin, antioxidant and toughening agent according to the formula to prepare a premix, and feed the premix and glass fiber into the twin screw The extruder is extruded and pelletized, that is, the temperature of the feeding section of the twin-screw extruder is ...

Embodiment 3

[0037]The thermoplastic nylon composite insulating material of this embodiment is composed of nano-montmorillonite and the following components by weight: 30 parts of nylon 66 resin, 60 parts of glass fiber, antioxidant (the mass ratio of antioxidant 1098 to antioxidant 1010) is a 1:1 mixture) 2.0 parts, toughening agent EAA (ethylene acrylic acid copolymer) 4 parts; the mass percentage content of the nano-montmorillonite in the composite material is 4.0%. The glass fiber is an alkali-free short fiber with a length of 3-6 mm and a diameter of 9-13 μm; the glass fiber is surface-treated with a silane coupling agent in advance.

[0038] The preparation method of the thermoplastic nylon composite insulating material in this embodiment is to mix nano-montmorillonite, nylon 66 resin, antioxidant and toughening agent according to the formula to prepare a premix, and feed the premix and glass fiber into the twin screw The extruder is extruded and pelletized, that is, the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com