Graphene electric-conduction powder coating material, preparation method and use method thereof

A technology of conductive powder and graphene powder, which is applied in the direction of conductive paint, epoxy resin paint, coating, etc., can solve the problems of unable to meet the mass production of paint, the price of single-layer graphene is extremely expensive, and increase costs, etc. Universality, enhanced impact toughness, and increased electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

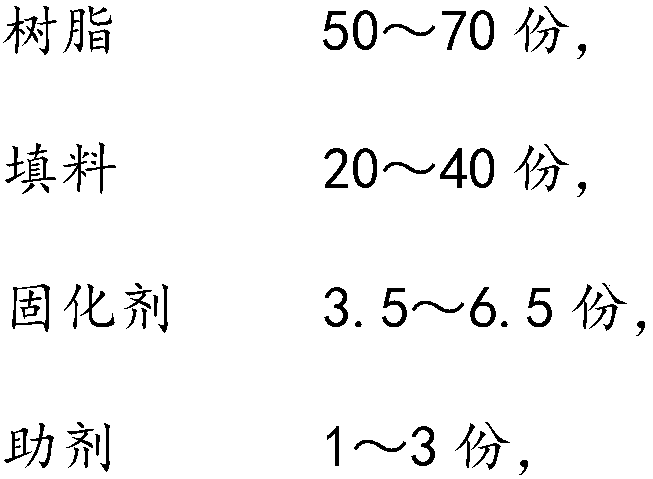

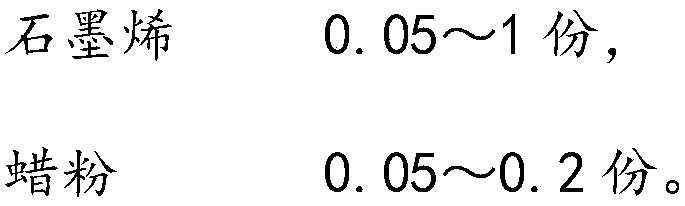

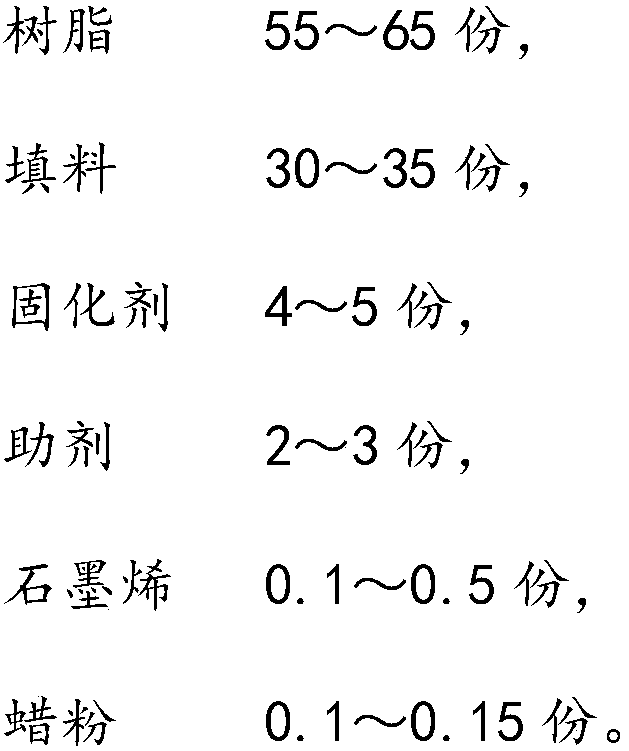

Method used

Image

Examples

Embodiment 1

[0083] 1200g of epoxy resin, 92g of modified dicyandiamide, 50g of additives, and 650g of filler are formulated into a masterbatch, which is melted, blended, extruded, tabletted, cooled, and pulverized to obtain a powder coating primer. Put 998.5g of bottom powder, 0.5g of graphene powder and 1g of polyethylene wax powder in the mixing kettle, feed protective nitrogen and stir at a stirring speed of 800rpm for 10min, during which the temperature of the mixing kettle is controlled at 65°C; stop controlling Stir gently, and after cooling, sift through a 150-mesh sieve to obtain a graphene powder sample powder, which can be solidified at 190°C for 10 minutes after electrostatic spraying.

[0084] Wherein, the auxiliary agent is a combination of leveling agent, defoamer, wetting agent, booster and antioxidant in a mass ratio of 12:4:6:2:1; the main component of the leveling agent is poly acrylate; the main component of the defoamer is benzoin; the main component of the wetting age...

Embodiment 2

[0087] 1200g of epoxy resin, 92g of triglycidyl isocyanurate, 50g of additives, and 650g of filler are formulated into a masterbatch, which is melt-blended and extruded, tabletted and cooled, and pulverized to obtain a powder coating base powder. Put 997.5g of bottom powder, 1.5g of graphene powder and 1g of polyamide wax powder in the mixing tank, pass through protective nitrogen and stir at a stirring speed of 800rpm for 10min, during which the temperature of the mixing tank is controlled at 65°C; stop controlling Stir gently, and after cooling, sift through a 150-mesh sieve to obtain a graphene powder sample powder, which can be solidified at 190°C for 10 minutes after electrostatic spraying.

[0088] Wherein, the auxiliary agent is a combination of leveling agent, defoamer, wetting agent, booster and antioxidant in a mass ratio of 10:5:5.6:3:1; the main component of the leveling agent is poly acrylate; the main component of the defoamer is benzoin; the main component of th...

Embodiment 3

[0091] 1200g of epoxy resin, 92g of dicyandiamide, 50g of additives, and 650g of filler are formulated into a masterbatch, which is melt-blended and extruded, tabletted and cooled, and pulverized to obtain a powder coating primer. Put 996g of bottom powder, 3g of graphene powder and 1g of polytetrafluoroethylene wax powder in the mixing kettle, feed protective nitrogen and stir at a stirring speed of 800rpm for 10min, during which the temperature of the mixing kettle is controlled at 65°C; stop controlling Stir gently, and after cooling, sift through a 150-mesh sieve to obtain a graphene powder sample powder, which can be solidified at 190°C for 10 minutes after electrostatic spraying.

[0092] Wherein, the auxiliary agent is a combination of leveling agent, defoamer, wetting agent, booster and antioxidant in a mass ratio of 15:3.5:6.3:1.6:1; the main component of the leveling agent is poly acrylate; the main component of the defoamer is benzoin; the main component of the wett...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com