A film structure of ultra-wide-angle laser, long-wave infrared dual-band high-strength anti-reflection film

An anti-reflection coating and long-wave infrared technology, applied in optics, optical components, instruments, etc., can solve the problems of being unable to withstand environmental tests such as sand, dust, salt spray, heat, temperature shock, etc., and low index requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

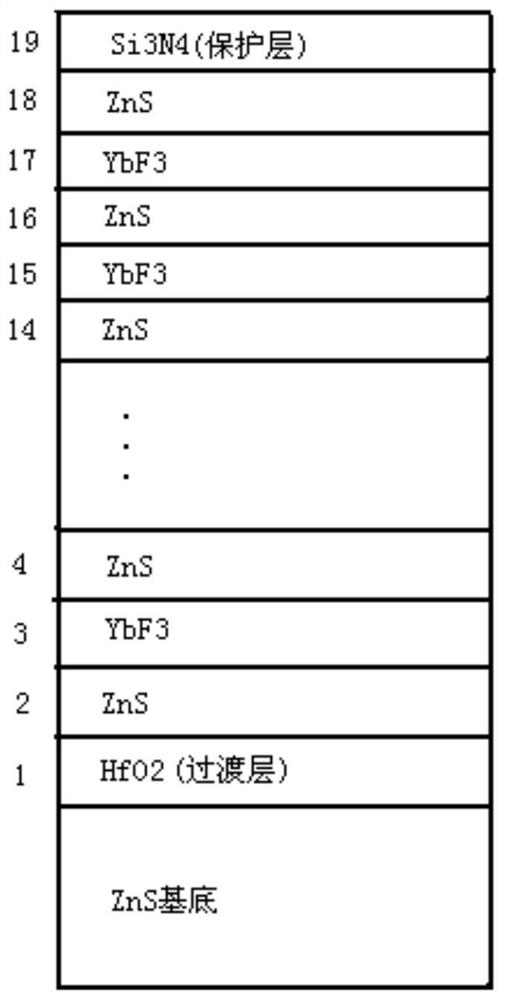

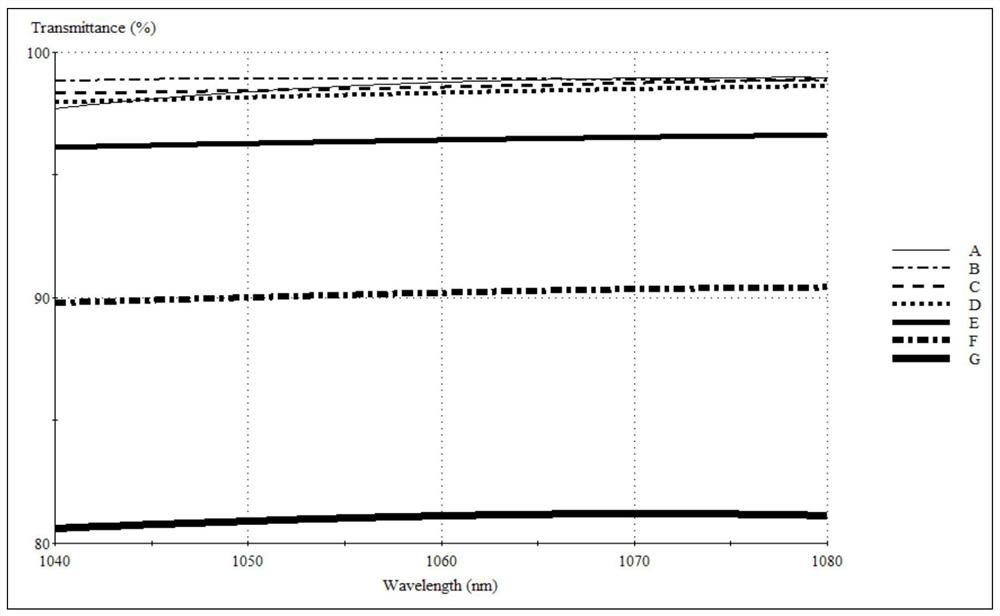

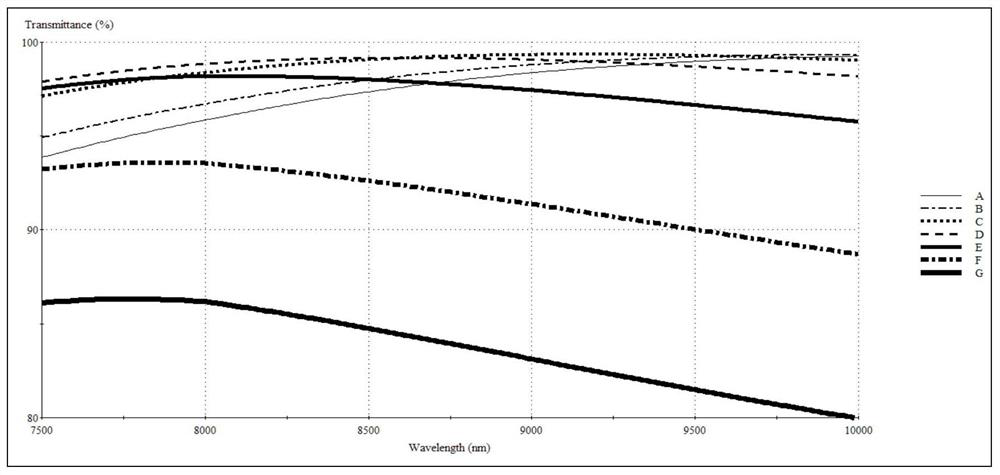

Embodiment 1

[0050] In this embodiment, the film system structure of the 1.064 μm laser incident on the ZnS substrate at an ultra-wide angle of 0° to 76° and the 7.5 μm to 10.0 μm long-wave infrared dual-band high-strength anti-reflection film consists of a zinc sulfide substrate and an anti-reflection film system. composition. The anti-reflection film system is composed of four layers of thin film materials. Wherein, the first film layer from inside to outside is hafnium oxide, which is plated on the surface of the zinc sulfide substrate; the second film layer is zinc sulfide, which is plated on the first film layer; the third film layer is Ytterbium fluoride is plated on the second film layer; the fourth film layer is zinc sulfide, and is plated on the third film layer, ..., the zinc sulfide film layer and the ytterbium fluoride film layer alternate to The eighteenth film layer; the nineteenth film layer is silicon nitride plated on the eighteenth film layer. That is, the number of lay...

Embodiment 2

[0056] The substrate adopts multi-spectral zinc sulfide, and the anti-reflection film system is composed of four layers of film materials. Wherein, the first film layer from inside to outside is hafnium oxide, which is plated on the surface of the zinc sulfide substrate; the second film layer is zinc sulfide, which is plated on the first film layer; the third film layer is Ytterbium fluoride is plated on the second film layer; the fourth film layer is zinc sulfide, and is plated on the third film layer, ..., the zinc sulfide film layer and the ytterbium fluoride film layer alternate to The eighteenth film layer; the nineteenth film layer is silicon nitride plated on the eighteenth film layer. That is, the number of layers of the anti-reflection film system is 19 layers in total, the first layer is a hafnium oxide film layer, the odd-numbered layers from the second layer to the 18th layer are ytterbium fluoride film layers, and the even-numbered layers are zinc sulfide film lay...

Embodiment 3

[0061] The substrate adopts multi-spectral zinc sulfide, and the anti-reflection film system is composed of four layers of film materials. Wherein, the first film layer from inside to outside is hafnium oxide, which is plated on the surface of the zinc sulfide substrate; the second film layer is zinc sulfide, which is plated on the first film layer; the third film layer is Ytterbium fluoride is plated on the second film layer; the fourth film layer is zinc sulfide, and is plated on the third film layer, ..., the zinc sulfide film layer and the ytterbium fluoride film layer alternate to The eighteenth film layer; the nineteenth film layer is silicon nitride plated on the eighteenth film layer. That is, the number of layers of the anti-reflection film system is 19 layers in total, the first layer is a hafnium oxide film layer, the odd-numbered layers from the second layer to the 18th layer are ytterbium fluoride film layers, and the even-numbered layers are zinc sulfide film lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Knoop hardness | aaaaa | aaaaa |

| laser radiation transmission | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com