Neonatal shading dressing and preparation method thereof

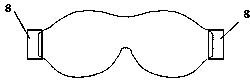

A neonatal, light-shielding layer technology, applied in dressings, viscous dressings, medical science and other directions, can solve the problems of easy movement and falling off, left-right movement of the light-shielding belt, up and down and left and right displacement of the eye mask, etc., and achieves good biocompatibility, doctors Easy to use and avoid excessive stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

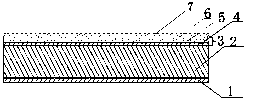

[0036] A newborn shading dressing is characterized in that it is composed of a shading layer, a support layer, a hydrogel layer and an isolation layer, and the hydrogel layer is coated on the surface of the support layer, wherein the hydrogel layer is composed of water, glycerin, polyacrylic acid resin, Composition of carbomer, tartaric acid, polyvinylpyrrolidone, glycylic aluminum and EDTA, the mass percentage of each component of the hydrogel is as follows: deionized water 55%, polyacrylic acid resin 8%, polyvinylpyrrolidone 3%, carbomer 1% , sodium carboxymethylcellulose 2%, tartaric acid 1%, glycerin 30%, aluminum glyoxate 0.03%, EDTA 0%; A kind of production technology of newborn shading dressing is as follows:

[0037] 1) Weigh the required polyacrylic acid resin, aluminum glycolate, EDTA, and glycerin according to the formula and mix to obtain the glycerin phase;

[0038] 2) Divide the deionized water into three equal parts, weigh the tartaric acid according to the form...

Embodiment 2

[0042] A newborn shading dressing is characterized in that it is composed of a shading layer, a support layer, a hydrogel layer and an isolation layer, and the hydrogel layer is coated on the surface of the support layer, wherein the hydrogel layer is composed of water, glycerin, polyacrylic acid resin, Composition of carbomer, tartaric acid, polyvinylpyrrolidone, glycylic aluminum and EDTA, the mass percentage of each component of the hydrogel is as follows: deionized water 70%, polyacrylic acid resin 4%, polyvinylpyrrolidone 0.4%, carbomer 3% , sodium carboxymethylcellulose 1%, tartaric acid 0.6%, glycerin 18%, aluminum glyoxate 0.1%, EDTA0.9%; A kind of production technology of newborn shading dressing is as follows:

[0043] 1) Weigh the required polyacrylic acid resin, aluminum glycolate, EDTA, and glycerin according to the formula and mix to obtain the glycerin phase;

[0044] 2) Divide the deionized water into three equal parts, weigh the tartaric acid according to the fo...

Embodiment 3

[0048] A newborn shading dressing is characterized in that it is composed of a shading layer, a support layer, a hydrogel layer and an isolation layer, and the hydrogel layer is coated on the surface of the support layer, wherein the hydrogel layer is composed of water, glycerin, polyacrylic acid resin, Composition of carbomer, tartaric acid, polyvinylpyrrolidone, glycylic aluminum and EDTA, the mass percentage of each component of the hydrogel is as follows: deionized water 60%, polyacrylic acid resin 10%, polyvinylpyrrolidone 4%, carbomer 2% , sodium carboxymethylcellulose 0%, tartaric acid 0.8%, glycerin 20%, aluminum glyoxate 0.1%, EDTA 0.1%; A kind of production process of newborn shading dressing is as follows:

[0049] 1) Weigh the required polyacrylic acid resin, aluminum glycolate, EDTA, and glycerin according to the formula and mix to obtain the glycerin phase;

[0050] 2) Divide the deionized water into three equal parts, weigh the tartaric acid according to the for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com