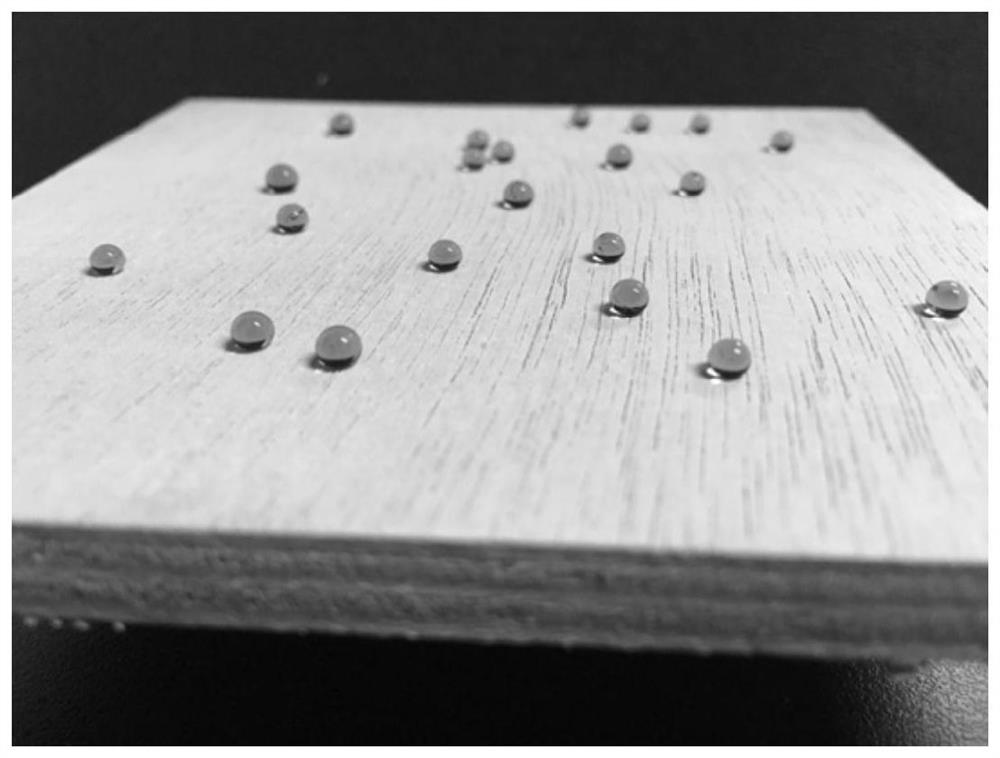

Preparation method of wood superhydrophobic bactericidal and anti-mildew functional modifier and wood modification method

A modifier and super-hydrophobic technology, applied in wood impregnation, wood treatment, impregnated wood, etc., can solve the problems of high toxicity, short storage time, poor loss resistance, etc., and achieve improved antiseptic and bactericidal performance, simple operation, and loss resistance sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0038] Specific embodiment one: the preparation method of wood superhydrophobic bactericidal and anti-mildew function modifier of the present embodiment, comprises the following steps:

[0039] 1. Weigh 1%-50% of hydrophobic polymer resin, 0.5%-5% of functional additives, 0.1%-1% of surfactant and the rest of the solvent according to mass percentage, and mix them at room temperature Stir for 0.1-1 hour to obtain functional reagent A;

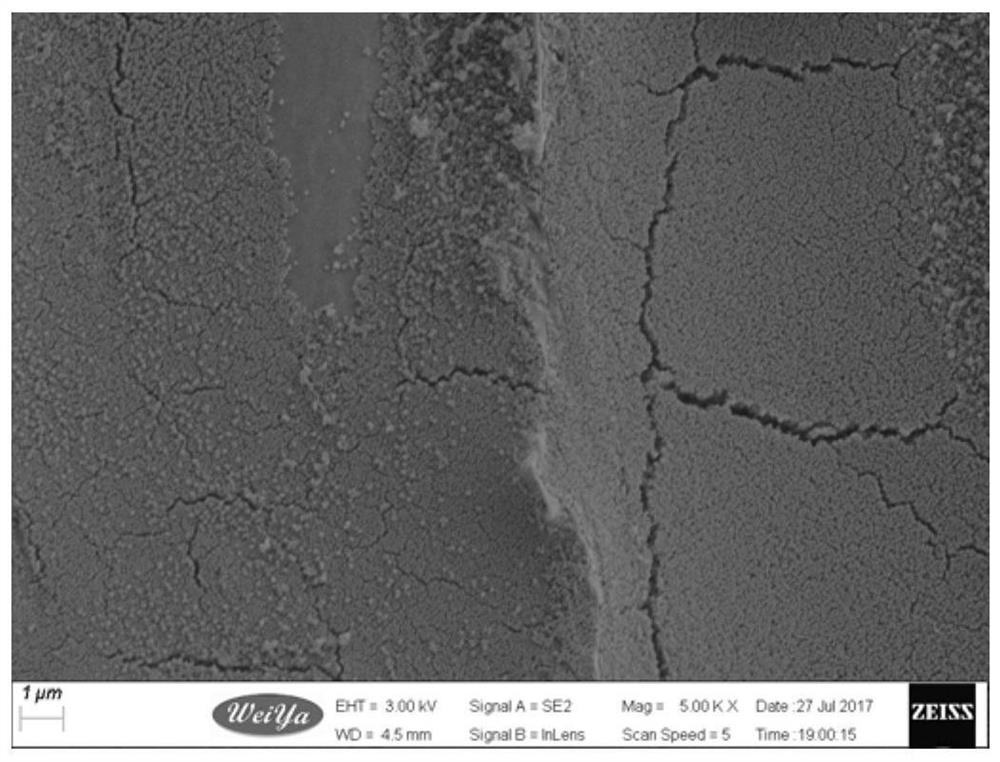

[0040] 2. Weigh 0.1%-5% of nanoparticles, 0.1%-2% of modifier and the rest of toluene according to mass percentage, mix and stir for 72-76 hours, then wash with acetone, and then centrifuge at 8000-9000rpm 3-5 times, then dry at 78-82°C for 12-14 hours to obtain functional reagent B;

[0041] 3. Add functional reagent B to functional reagent A. The mass of functional reagent B is 0.1%-1% of the mass of functional reagent A. Ultrasound for at least 30 minutes to obtain the wood modifier.

specific Embodiment approach 2

[0042] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, the hydrophobic polymer resin is a fluorocarbon resin with less than 8 F atoms. Others are the same as in the first embodiment.

[0043] In this embodiment, the fluorocarbon resin is purchased from Shangmeng Technology Wuxi Co., Ltd., which meets the environmental protection standards of Europe, Japan and the United States.

specific Embodiment approach 3

[0044]Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step one, the functional auxiliary agent is a mixture composed of iodopropynyl butyl carbamate (IPBC) and benzimidazole in any proportion . Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

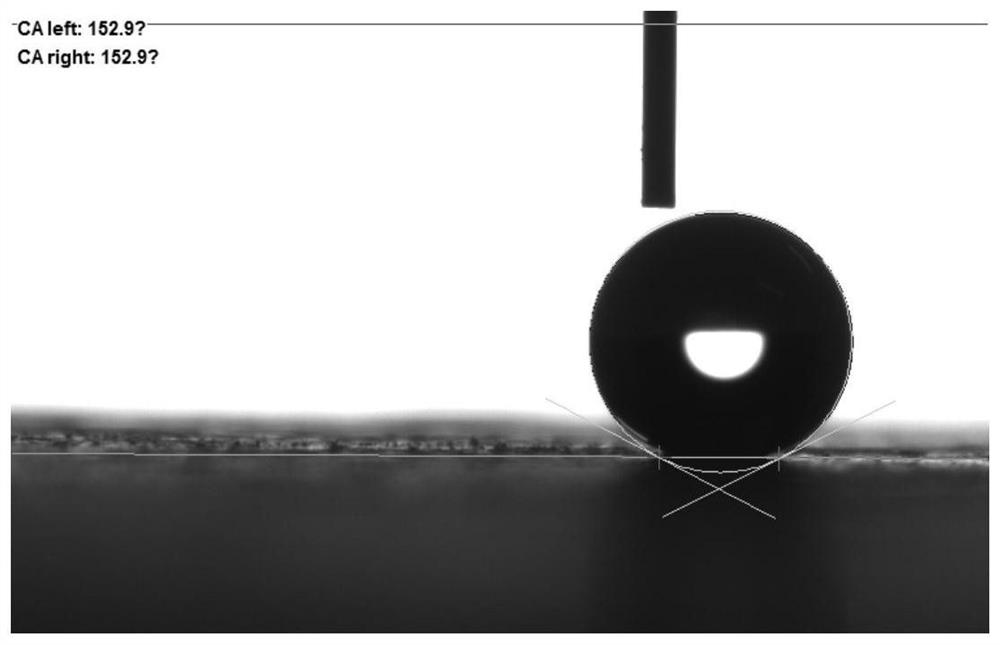

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com