Method for producing high-purity sulfur through sulfur paste extraction

A high-purity, extraction technology, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of low utilization value, high price of leaching agent, loss in the leaching process, etc. Economic and social benefits, the effect of easy recovery and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

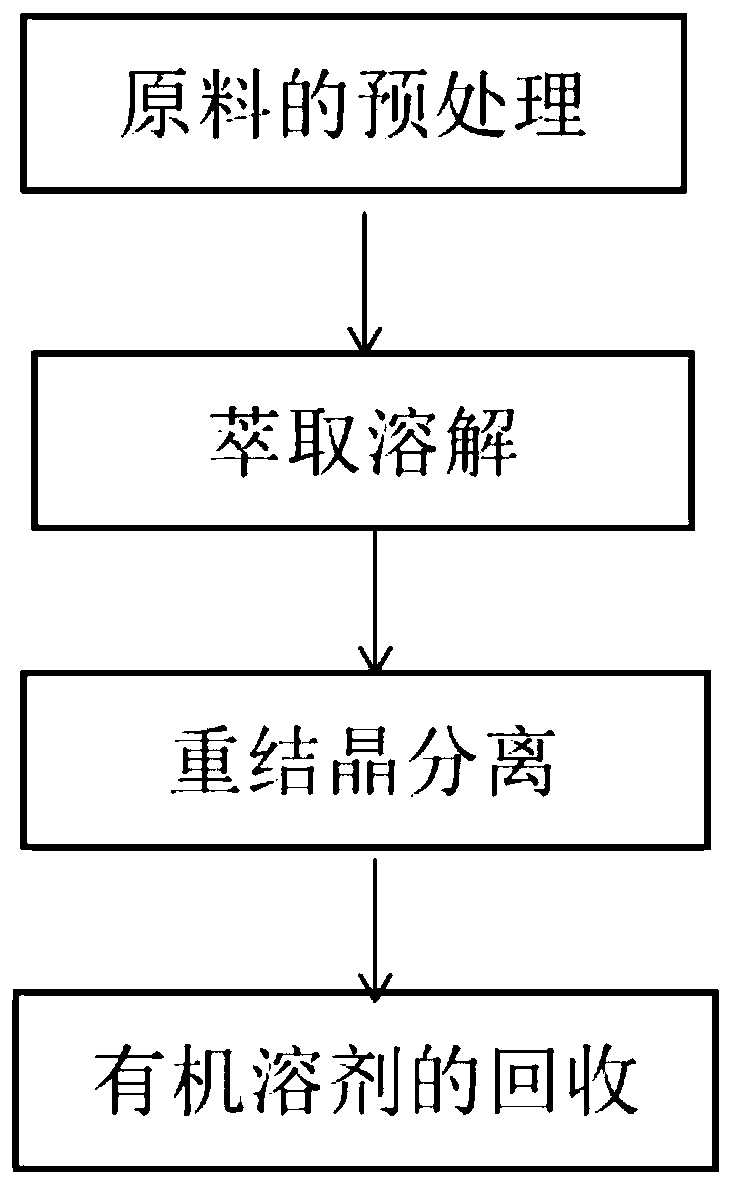

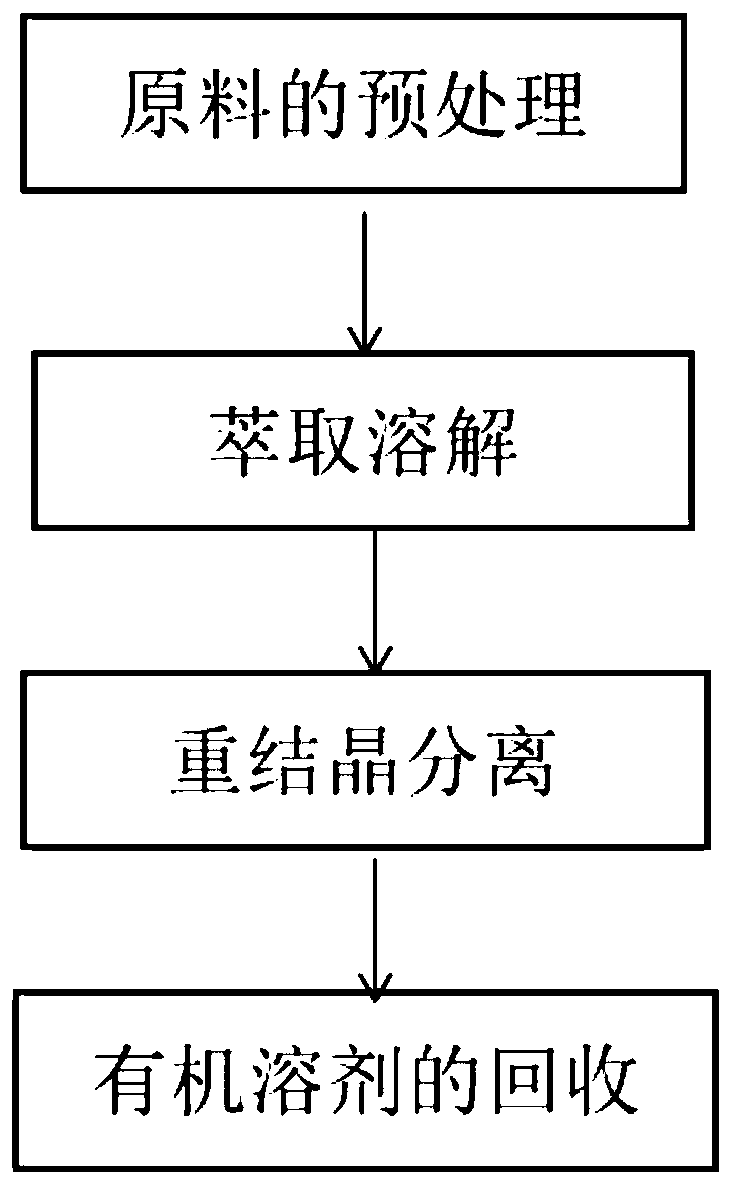

[0030] Such as figure 1 Shown, a kind of sulfur paste extraction method of the present embodiment produces high-purity sulfur, comprises following specific steps:

[0031] (1) Pretreatment of raw materials:

[0032] The dried sulfur paste is crushed and sieved with a pulverizer until the particle size is less than 30mm.

[0033] (2) Extraction and dissolution:

[0034] Weigh 100g of the above-mentioned sulfur paste and put it into a reaction kettle with a steam heating jacket, then add 220g of 200# solvent oil, heat to 130°C, and extract for 3 hours.

[0035] (3) Recrystallization separation:

[0036] The reaction solution obtained in step (2) is subjected to heat preservation and filtration treatment, and then it is introduced into a crystallizer for cooling crystallization, the crystallization temperature is 80°C, and the crystallization time is 1.5h; after cooling crystallization and solid-liquid separation are completed, the target Required sulfur; the quality of sulfu...

Embodiment 2

[0040] Such as figure 1 Shown, a kind of sulfur paste extraction method of the present embodiment produces high-purity sulfur, comprises following specific steps:

[0041] (1) Pretreatment of raw materials:

[0042] The dried sulfur paste is crushed and sieved with a pulverizer until the particle size is less than 15mm.

[0043] (2) Extraction and dissolution:

[0044] Weigh 100g of the above-mentioned sulfur paste and put it into a reaction kettle with a steam heating mantle, then add 220g of heavy benzene, heat to 170°C, and extract for 1.0h.

[0045] (3) Recrystallization separation:

[0046] The reaction solution obtained in step (2) is subjected to heat preservation and filtration treatment, and then introduced into a crystallizer for cooling crystallization, the crystallization temperature is 50°C, and the crystallization time is 1.0h; after cooling crystallization and solid-liquid separation are completed, the target Required sulfur; the quality of sulfur after dryi...

Embodiment 3

[0050] Such as figure 1 Shown, a kind of sulfur paste extraction method of the present embodiment produces high-purity sulfur, comprises following concrete steps:

[0051] (1) Pretreatment of raw materials:

[0052] The dried sulfur paste is crushed and sieved with a pulverizer until the particle size is less than 20mm.

[0053] (2) Extraction and dissolution:

[0054]Take by weighing 100g of the above-mentioned sulfur paste and pack it into a reaction kettle with a steam heating jacket, then add a mixed solvent of 400g xylene and 200# solvent oil (the mass ratio of xylene and 200# solvent oil is 1:1), and heat to 140°C, extraction reaction 2.0h.

[0055] (3) Recrystallization separation:

[0056] The reaction solution obtained in step (2) is subjected to heat preservation and filtration treatment, and then introduced into a crystallizer for cooling crystallization, the crystallization temperature is 90°C, and the crystallization time is 0.3h; after cooling crystallization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com