Bismuth sulfide/titanium dioxide composite material film, and preparation method and application thereof

A technology of composite thin film and titanium dioxide, which is applied in the field of bismuth sulfide/titanium dioxide composite thin film and its preparation, can solve the problems of low visible light absorption performance and poor film repeatability, and achieve improved photoelectric performance, high repeatability, and uniform crystallization control sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

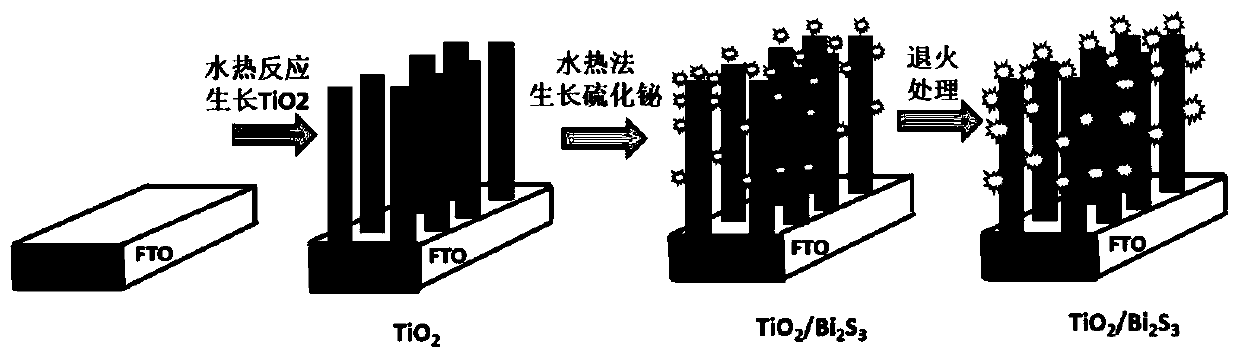

Method used

Image

Examples

Embodiment 1

[0052] (1) After scrubbing the FTO glass substrate with detergent, then ultrasonically cleaned with acetone, alcohol and deionized water for 15min in turn, then dried with a nitrogen gun, and then the FTO substrate was subjected to ozone treatment for 15min;

[0053] (2) deionized water and concentrated hydrochloric acid are mixed according to volume ratio of 1:1, and placed on a magnetic stirrer for magnetic stirring for 20min to obtain a hydrochloric acid solution; then a pipette is used to absorb tetrabutyl titanate, and titanium is added to the hydrochloric acid solution tetrabutyl titanate, and continue stirring for 10min to obtain a reaction solution; wherein, the consumption of tetrabutyl titanate is 1.5% of the volume of the hydrochloric acid solution;

[0054] (3) Put the conductive glass dried in step (1) into the inner lining of the reactor with the conductive surface facing down, the angle between the glass and the inner substrate is 45°, add the reaction solution o...

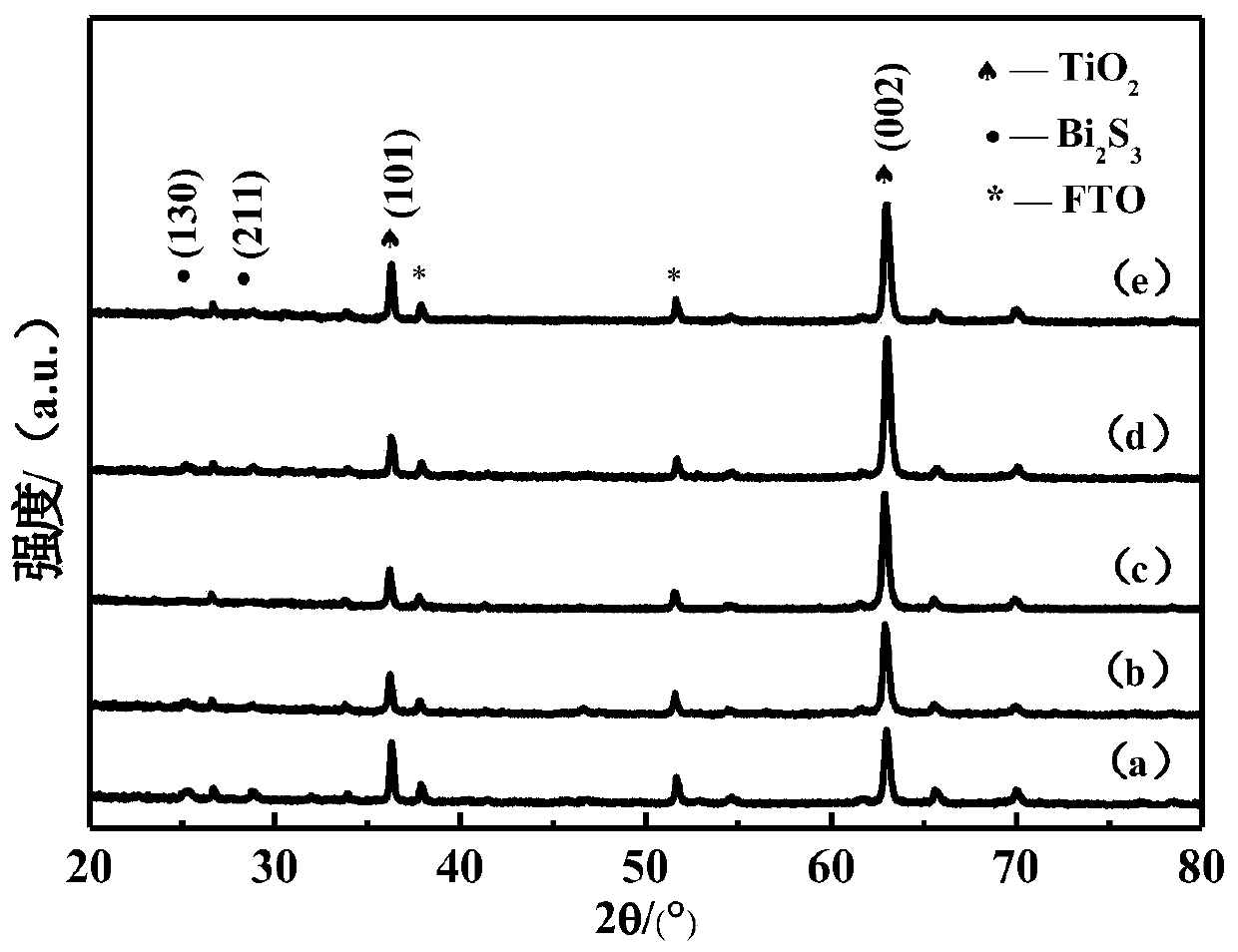

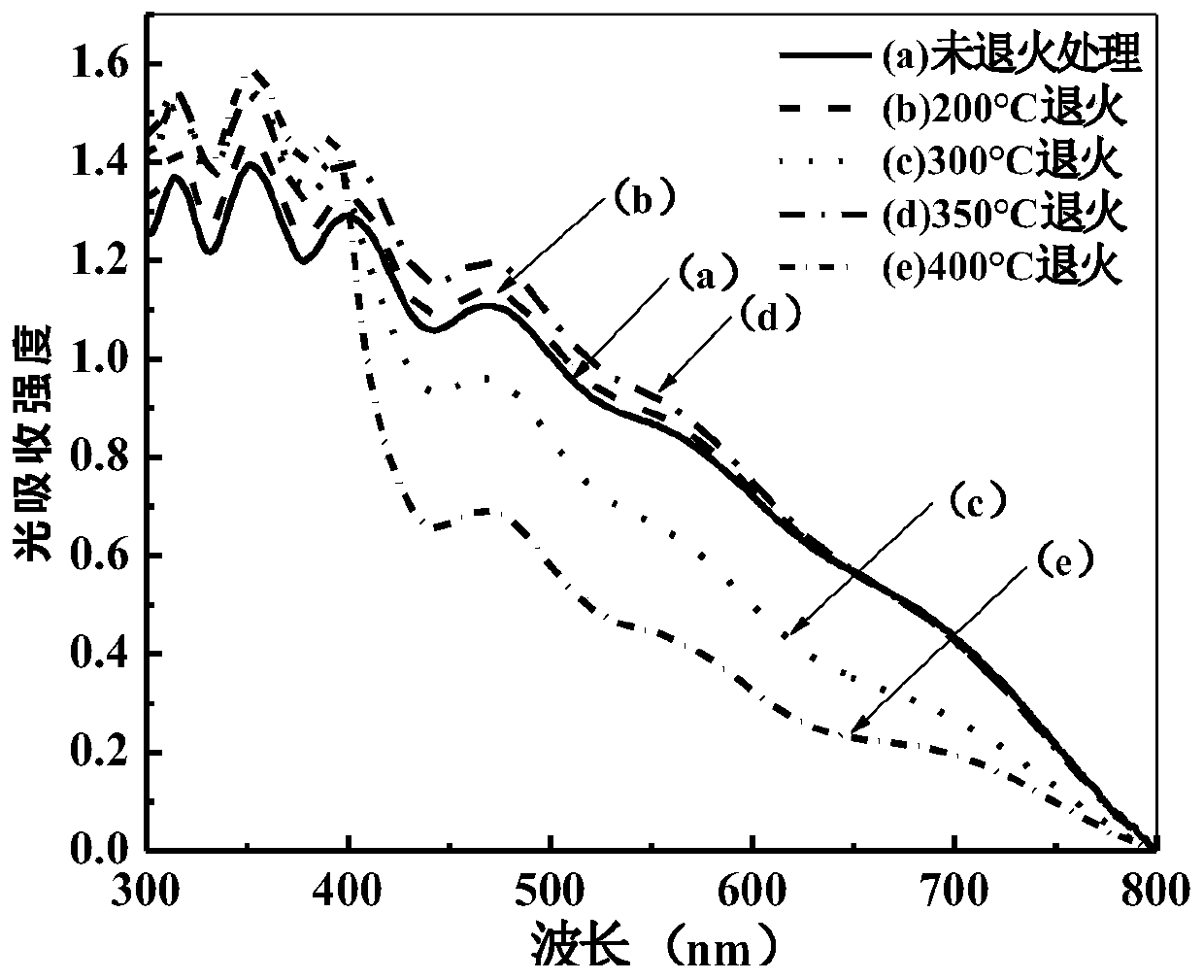

Embodiment 2

[0060] The difference between this embodiment and Embodiment 1 is that in step (7), the annealing temperature is 300° C. and the time is 40 min, and the remaining steps are the same as those in Embodiment 1.

Embodiment 3

[0062] The difference between this embodiment and Embodiment 1 is that in step (7), the annealing temperature is 350° C. and the time is 40 min, and the remaining steps are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com