Functional monomers used for catalytic degradation of organophosphate and preparation method of porous imprinted polymer

A technology of organophosphate and imprinted polymers, which is applied in organic chemistry and other fields, can solve the problems of slow mass transfer rate and small specific surface area, and achieve high-efficiency degradation and good catalytic degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

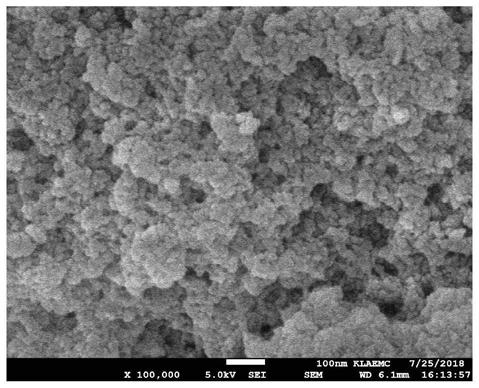

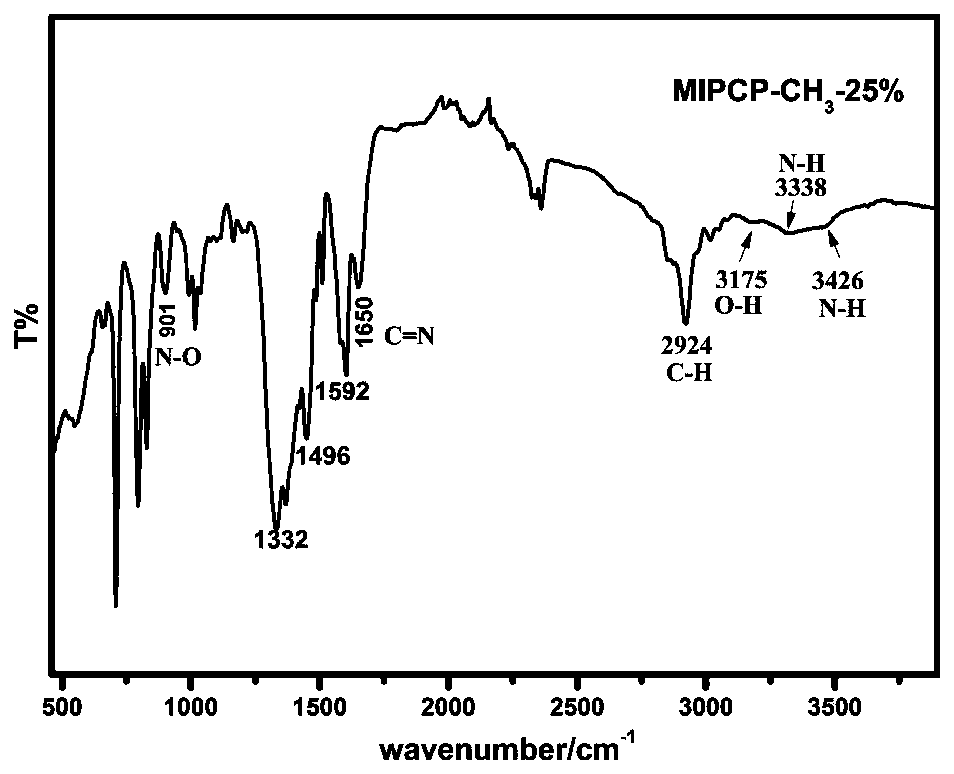

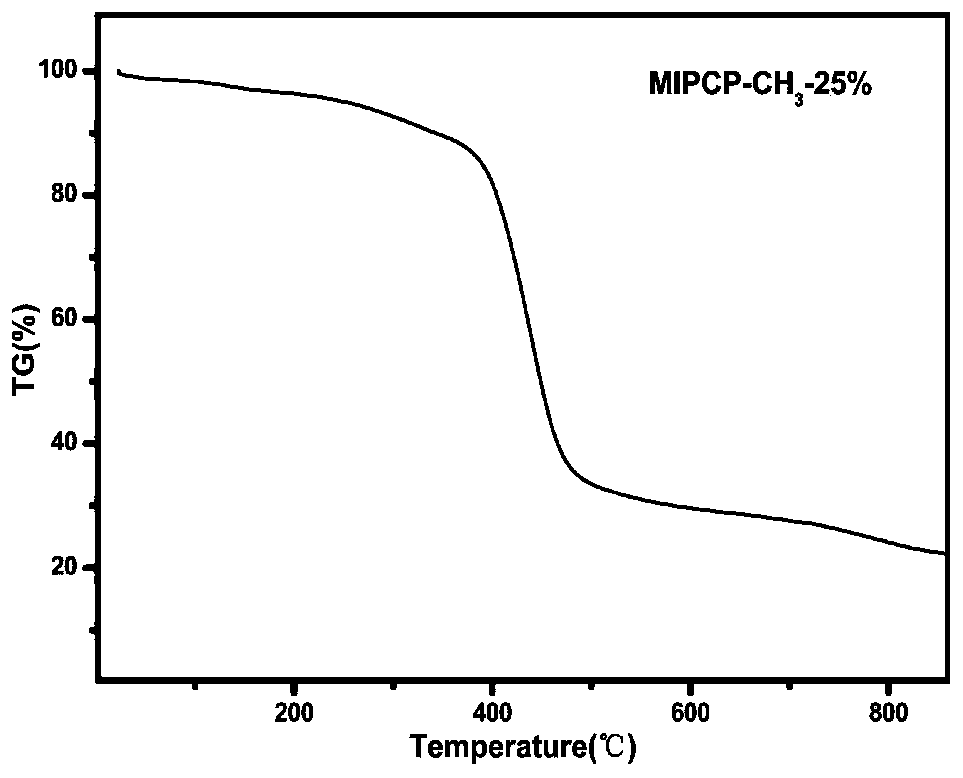

Image

Examples

Embodiment 1

[0038] 1.1, the preparation of functional monomer 5a, its structure is as follows:

[0039]

[0040] (1) Synthesis of compound 2a in the preparation of functional monomer step

[0041] In a thick-walled glass bottle equipped with a magnet, add 1.69g of N-methylethylenediamine, 2.84g of ethyl trifluoroacetate and 200ml of chloroform under an ice-water bath, slowly rise to room temperature, react for two days, and use saturated Extract with brine, vacuumize to obtain a light yellow solid (1.7g, 60%), then at room temperature, dissolve 1.7g of light yellow liquid, 1.9g of vinylbenzyl chloride and 8g of potassium carbonate in 100ml of chloroform, at 40 React at -60°C for two days, filter, and pass through a silica gel column (dichloromethane / methanol: 50 / 1) to obtain the target product 2a (1.54g, 60%).

[0042] (2) Synthesis of compound 3a in the step of preparing functional monomer

[0043] In a thick-walled glass bottle equipped with a magnet, add 1.54g of the above-mention...

Embodiment 2

[0058] 2.1, the preparation of functional monomer 4b, its structure is as follows:

[0059]

[0060] (1) Synthesis of compound 2b in the step of preparing functional monomer

[0061] In a thick-walled glass bottle equipped with a magnet, add 3.2g of N-ethylethylenediamine, 5.89g of ethyl trifluoroacetate and 200ml of chloroform under an ice-water bath, slowly rise to room temperature, react for two days, and use saturated Extract with brine, vacuumize to obtain light yellow solid (3.4g, 61%), then at room temperature, the resulting 3.4g light yellow liquid, 3.8g vinylbenzyl chloride and 12g potassium carbonate are dissolved in 200ml chloroform, in React at 40-60°C for two days, filter, and pass through a silica gel column (dichloromethane / methanol: 60 / 1) to obtain the target product 2b (2.6g, 60%).

[0062] (2) Synthesis of compound 3b in the step of preparing functional monomer

[0063] In a thick-walled glass bottle equipped with a magnet, add 2.6g of the above-mentione...

Embodiment 3

[0074] 3.1, the preparation of functional monomer 5c, its structure is as follows:

[0075]

[0076] (1) Synthesis of compound 2c in the step of preparing functional monomer

[0077] In a thick-walled glass bottle equipped with a magnet, add 3.06g N-benzylethylenediamine, 2.84g ethyl trifluoroacetate and 200ml trichloromethane under ice-water bath, slowly rise to room temperature, react for two days, use saturated Extract with brine, vacuumize to obtain a light yellow solid (2.9g, 60%), then at room temperature, dissolve 2.9g of light yellow liquid, 1.9g of vinylbenzyl chloride and 8g of potassium carbonate in 100ml of chloroform, in React at 40-60°C for two days, filter, and pass through a silica gel column (dichloromethane / methanol: 50 / 1) to obtain the target product 2c (2.7g, 60%).

[0078] (2) Synthesis of compound 3c in the step of preparing functional monomer

[0079] In a thick-walled glass bottle equipped with a magnet, add 2.7g of the above-mentioned 2c, 8g of so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com