Heatproof flame-retardant insulating paint, and preparation method thereof

An insulating paint, heat-resistant technology, used in coatings, fire-retardant coatings, etc., to achieve the effects of improving flame retardancy and heat resistance, fast film formation, and avoiding dry cracking of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

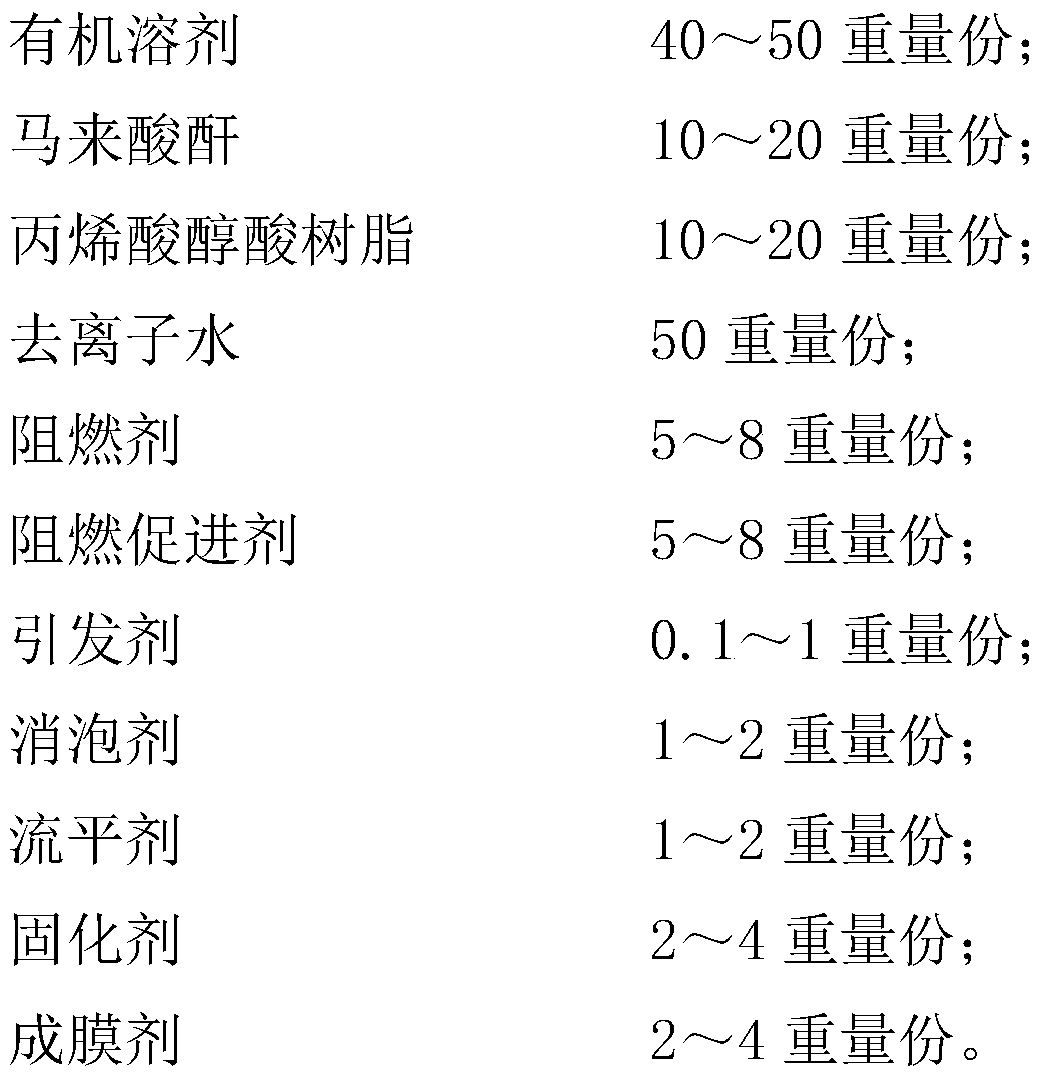

[0024] A heat-resistant and flame-retardant insulating varnish, comprising the following materials in parts by weight:

[0025]

[0026]

[0027] The preparation method of the above-mentioned heat-resistant and flame-retardant insulating varnish is characterized in that it is prepared by the following method:

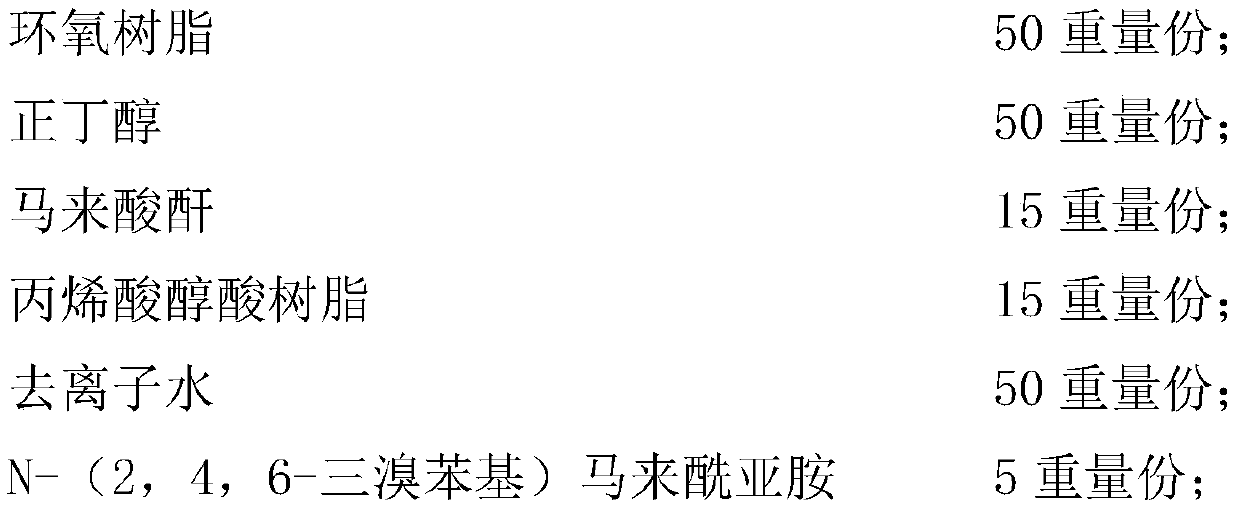

[0028] (1) First react 50 parts by weight of epoxy resin, 15 parts by weight of maleic anhydride, 15 parts by weight of acrylic alkyd resin and 50 parts by weight of n-butanol under the protection of an inert gas at 110°C for 1 hour, then add 50 parts by weight of High-speed centrifugal dispersion with deionized water to obtain epoxy prepolymer emulsion;

[0029] (2) under the inert gas environment of 70 ℃, the epoxy prepolymer emulsion that above-mentioned step gained is dripped into 5 weight parts N-(2,4,6-tribromophenyl) maleimide at a uniform speed, and then Constant temperature reaction for 1 hour;

[0030] (3) At 110°C, 5 parts by weight of phenyl methacry...

Embodiment 2

[0033] A heat-resistant and flame-retardant insulating varnish, comprising the following materials in parts by weight:

[0034]

[0035]

[0036] The preparation method of the above-mentioned heat-resistant and flame-retardant insulating varnish is characterized in that it is prepared by the following method:

[0037] (1) First react 50 parts by weight of epoxy resin, 15 parts by weight of maleic anhydride, 15 parts by weight of acrylic alkyd resin and 50 parts by weight of n-butanol under the protection of an inert gas at 110°C for 1 hour, then add 50 parts by weight of High-speed centrifugal dispersion with deionized water to obtain epoxy prepolymer emulsion;

[0038] (2) under the inert gas environment of 70 ℃, the epoxy prepolymer emulsion that above-mentioned step gained is dripped into 5 weight parts N-(2,4,6-tribromophenyl) maleimide at a uniform speed, and then Constant temperature reaction for 1 hour;

[0039] (3) At 110°C, 6.5 parts by weight of phenyl methac...

Embodiment 3

[0042] A heat-resistant and flame-retardant insulating varnish, comprising the following materials in parts by weight:

[0043]

[0044] The preparation method of the above-mentioned heat-resistant and flame-retardant insulating varnish is characterized in that it is prepared by the following method:

[0045] (1) First react 50 parts by weight of epoxy resin, 15 parts by weight of maleic anhydride, 15 parts by weight of acrylic alkyd resin and 50 parts by weight of n-butanol under the protection of an inert gas at 110°C for 1 hour, then add 50 parts by weight of High-speed centrifugal dispersion with deionized water to obtain epoxy prepolymer emulsion;

[0046] (2) under the inert gas environment of 70 ℃, the epoxy prepolymer emulsion that above-mentioned step gained is dripped into 5 weight parts N-(2,4,6-tribromophenyl) maleimide at a uniform speed, and then Constant temperature reaction for 1 hour;

[0047] (3) At 110°C, 8 parts by weight of phenyl methacrylate, 0.5 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com