A kind of high-salt-resistant viscoelastic surfactant cleaning fracturing fluid and preparation method thereof

A surfactant and clean fracturing fluid technology, applied in the field of acidizing fracturing agents, can solve the problems of lowering the viscosity of VES fracturing fluid and restricting the development and application of VES fracturing fluid, and achieve good stability and universality , expand the range of fracturing formations, and improve the effect of temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A high-salt-resistant viscoelastic surfactant cleaning fracturing fluid system and a preparation method thereof, comprising the following components:

[0042] In terms of mass percentage: 2.0-6.0% cationic surfactant, 2.0-10.0% inorganic salt, 84.0-96.0% water.

[0043] The cationic surfactant is an ultra-long-chain fatty amide cationic surfactant with a special substitution structure, and the structure is as follows:

[0044] Among them, R 1 'Selected from saturated alkyl groups with 16≤n≤24 carbons, unsaturated alkyl groups with 16≤n≤24 carbons, R 1 Selected from saturated alkyl groups with 16≤n≤24 carbons and unsaturated alkyl groups with 16≤n≤24 carbons, R 2 It is selected from saturated alkyl groups with 3≤C≤7 carbons, unsaturated alkyl groups with 3≤C≤7 carbon atoms, and short-chain (C≤5) alkylbenzenes.

[0045] The preparation method of the ultra-long-chain fatty amide cationic surfactant with special substitution structure is as follows:

[0046]Put 5.0-...

Embodiment 1

[0051] The preparation method of oleic acid amidopropyl butyl ammonium bromide:

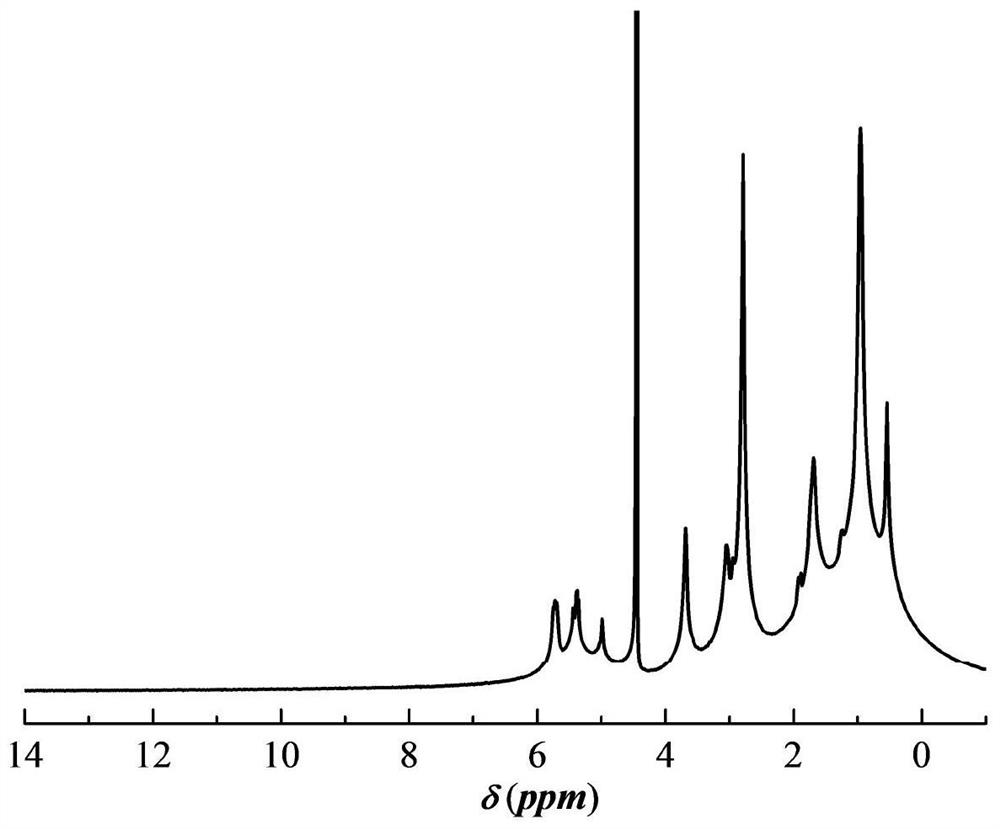

[0052] Take 24.0 g of oleic amidopropyl dimethyl tertiary amine in a single-necked bottle, add 35 mL of absolute ethanol as a solvent, raise the temperature to 60 ° C, slowly add 9.0 g of bromobutane dropwise, continue the reaction for 12 h, and distill under reduced pressure to obtain a yellow viscous Thick liquid, add acetone to dissolve, then refrigerate at 0°C for 10h to precipitate a white solid, filter and dry to obtain the final product with a yield of 90-96%. Its NMR spectrum is as figure 1 Shown: 1 H NMR (300MHz,D 2 O)δ: 0.75(t,2H), 0.96~1.22(m,28H), 1.64~1.73(m,3H), 2.57~2.96(m,9H), 3.02(t,2H), 3.56(s,2H ), 5.33~5.46(m,1H), 5.51~5.62(m,1H).

[0053] 1) Add 3.0wt% oleic acid amidopropyl butyl ammonium bromide prepared in Example 1 to distilled water, stir for 60 minutes, and mix well to obtain a clean fracturing fluid system; put the clean fracturing fluid system in a rheometer In t...

Embodiment 2

[0058] The preparation method of erucamide propylhexyl ammonium bromide:

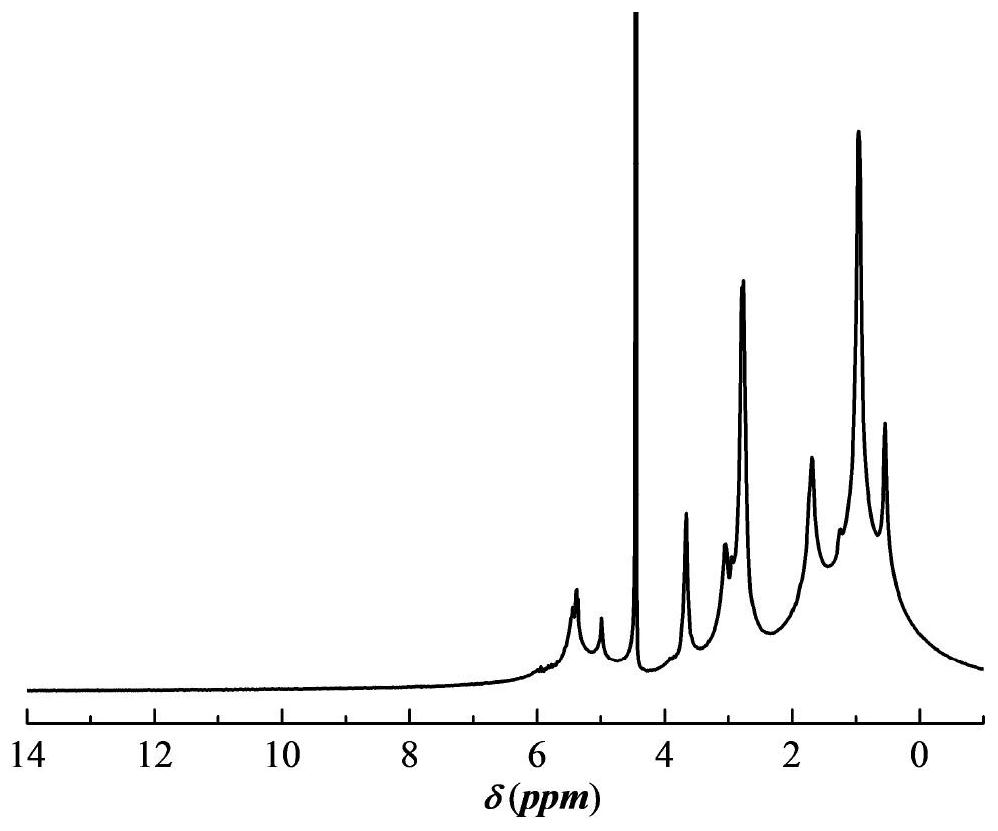

[0059] Take 27.0 g of erucamidopropyl dimethyl tertiary amine in a single-necked bottle, add 35 mL of absolute ethanol as a solvent, raise the temperature to 60 ° C, slowly add 12.0 g of bromohexane dropwise, continue the reaction for 14 hours, and distill under reduced pressure to obtain a yellow viscous Thick liquid, add acetone to dissolve, then refrigerate at 0°C for 7h to precipitate a white solid, filter and dry to obtain the final product with a yield of 88-96%. Its NMR spectrum is as figure 2 Shown: 1 H NMR (300MHz,D 2 O)δ: 0.77(t,2H), 0.94~1.23(m,32H), 1.66~1.75(m,3H), 2.57~2.94(m,9H), 3.04(t,2H), 3.61(s,2H ), 5.31~5.54(m,1H).

[0060] 1) Add 3.0 wt% of erucamide propylhexyl ammonium bromide prepared in Example 2 to distilled water, stir for 60 minutes, and mix well to obtain a clean fracturing fluid system; place the clean fracturing fluid system in a rheometer In cylinder, at 90℃, 170s ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com