Mussel-shell micro-nano fruit and vegetable cleaning agent and preparation method thereof

A fruit and vegetable cleaning agent, mussel shell technology, applied in the directions of detergent compounding agents, detergent compositions, chemical instruments and methods, etc., can solve the problems of high cost and complicated process, and achieve the advantages of reducing the cost of raw materials and avoiding secondary pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

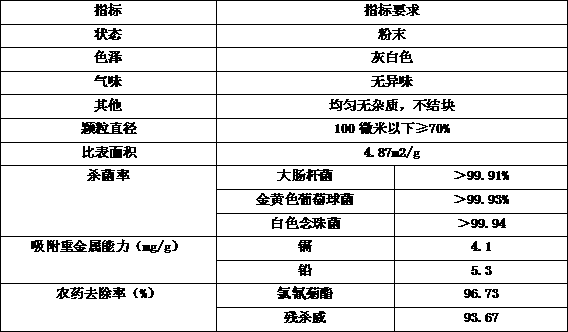

Embodiment 1

[0029] 1. Experimental instruments and reagents

[0030] 2. Test method

[0031] 2.1 Fresh mussel shells are cleaned, cleaned and dried.

[0032] 2.2 Put the dried mussel shells into a tube furnace, infiltrate with inert gas (N2), the gas flow rate is 100ml / min, and raise the temperature to 800°C at a heating rate of 10°C / min and keep it for 3 hours, then cool to room temperature Then take it out.

[0033] 2.3 Mix the taken out mussel shells with a mass fraction of 25% KOH and the treated shell powder according to the ratio of material to liquid of 1:1, soak them at room temperature for 2 hours, put them in a drying oven, and put them in a drying oven at 120°C Dry to constant mass.

[0034] 2.4 Activate the impregnated mixture in a muffle furnace, raise the temperature to 500°C at a rate of 10°C / min, and keep it warm for 2 hours. After cooling to room temperature, wash with distilled water, then dry the sample at 105°C for 6 hours, and seal it up. spare.

[0035] 2.5 The ...

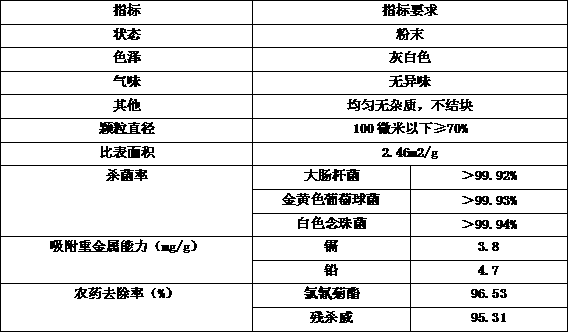

Embodiment 2

[0046] 1. Experimental instruments and reagents

[0047] 2. Test method

[0048] 2.1 Fresh mussel shells are cleaned, cleaned and dried.

[0049] 2.2 Put the dried mussel shells into a tube furnace, permeate with inert gas (N2), the gas flow rate is 100ml / min, and raise the temperature to 900°C at a heating rate of 10°C / min and keep it for 3 hours, then cool to room temperature Then take it out.

[0050]2.3 Mix the taken out mussel shells with the mass fraction of 25% KOH and the treated shell powder evenly according to the ratio of material to liquid of 2:1, soak them at room temperature for 2 hours, put them in a drying box at 120°C Dry to constant mass.

[0051] 2.4 Activate the impregnated mixture in a muffle furnace, raise the temperature to 500°C at a rate of 10°C / min, and keep it warm for 2 hours. After cooling to room temperature, wash with distilled water, then dry the sample at 105°C for 6 hours, and seal it up. spare.

[0052] 2.5 The dried sample was subjected...

Embodiment 3

[0063] 1. Experimental instruments and reagents

[0064] 2. Test method

[0065] 2.1 Fresh mussel shells are cleaned, cleaned and dried.

[0066] 2.2 Put the dried mussel shells into a tube furnace, permeate with inert gas (N2), the gas flow rate is 100ml / min, and raise the temperature to 1000°C at a heating rate of 10°C / min and keep it for 3 hours, then cool to room temperature Then take it out.

[0067] 2.3 Mix the taken-out mussel shells with a mass fraction of 25% K2CO3 and the treated shell powder according to the ratio of material to liquid of 1:1, soak them at room temperature for 2 hours, put them in a drying box, and store them at 120°C Dry to constant mass.

[0068] 2.4 Activate the impregnated mixture in a muffle furnace, raise the temperature to 500°C at a rate of 10°C / min, and keep it warm for 2 hours. After cooling to room temperature, wash with distilled water, then dry the sample at 105°C for 6 hours, and seal it up. spare.

[0069] 2.5 The dried sample wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com