Method for modifying phosphate-coated lithium-rich manganese-based cathode material

A lithium-rich manganese-based, cathode material technology, used in battery electrodes, electrical components, electrochemical generators, etc., can solve problems such as voltage decay, capacity decay, structural instability, etc. The effect of the generation of oxygen vacancies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

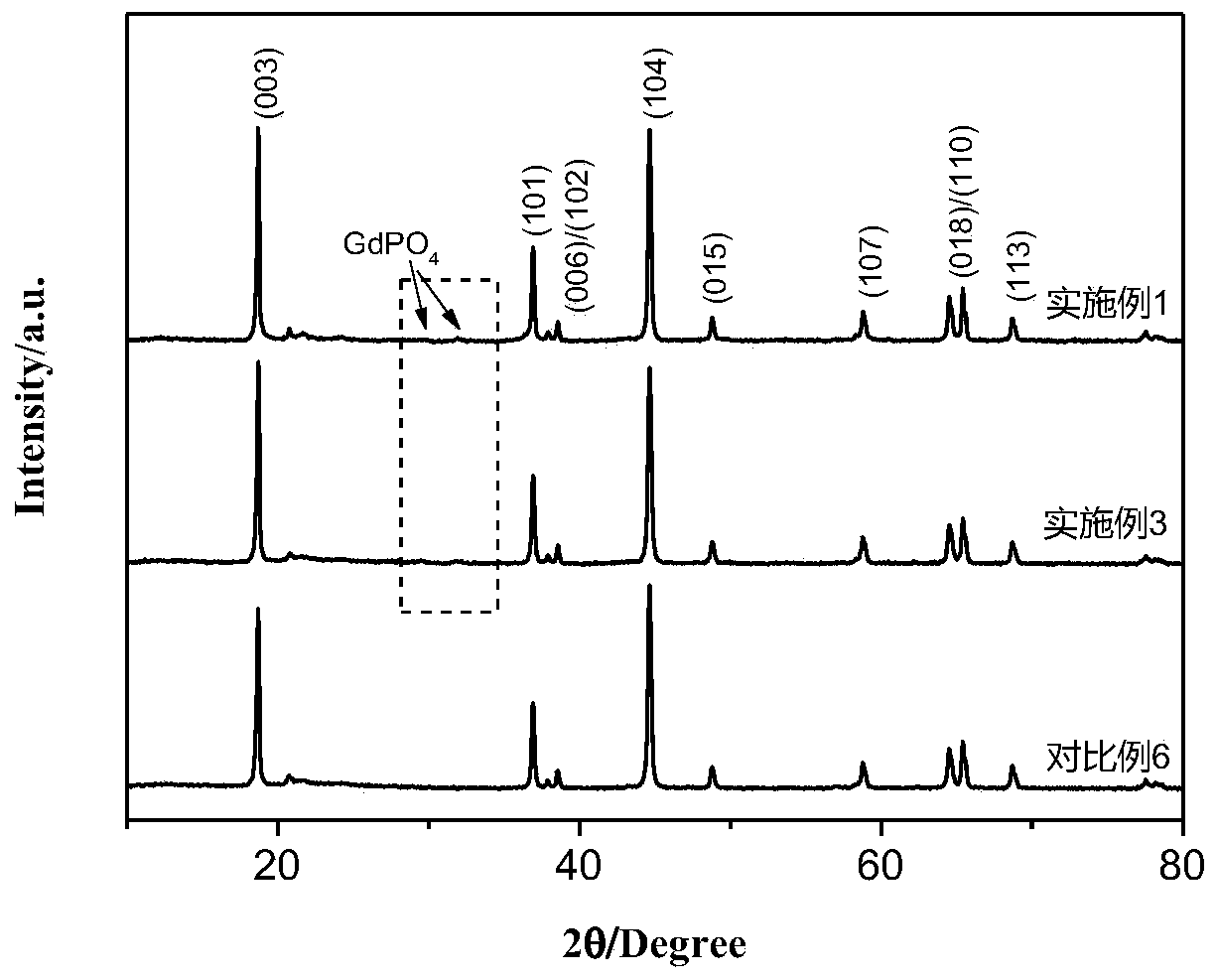

Embodiment 1

[0031] Embodiment 1: A method for modifying a phosphate-coated lithium-rich manganese-based positive electrode material, comprising the following steps:

[0032] (1) Evenly disperse 0.5 g of the prepared lithium-rich manganese-based positive electrode material in 70 mL of a mixed solution of deionized water and ethanol with a volume ratio of 1:1, and add 0.5 g of surfactant DTAB to obtain solution A;

[0033] (2) 1.3539g gadolinium nitrate and 0.2699g diammonium hydrogen phosphate were dissolved in 100mL deionized water respectively to make solutions B and C;

[0034] (3) Add solutions B and C dropwise to the dispersion of the lithium-rich manganese-based positive electrode material successively under stirring at room temperature, adjust the pH value of the solution to 10, and allow the solutions C and B to react and deposit in situ on the lithium-rich material. surface;

[0035] (4) Aging the solution for 3 hours under stirring at room temperature, then evaporating to drynes...

Embodiment 2

[0037] Embodiment 2: A method for modifying a phosphate-coated lithium-rich manganese-based positive electrode material, comprising the following steps:

[0038] (1) Evenly disperse 0.5 g of the prepared lithium-rich manganese-based positive electrode material in 70 mL of a mixed solution of deionized water and ethanol with a volume ratio of 1:1, and add 0.5 g of surfactant PVP to obtain solution A;

[0039] (2) 1.3539g gadolinium nitrate and 0.2699g diammonium hydrogen phosphate were dissolved in 100mL deionized water respectively to make solutions B and C;

[0040] (3) Add solutions B and C dropwise to the dispersion of the lithium-rich manganese-based positive electrode material successively under stirring at room temperature, adjust the pH value of the solution to 10, and allow the solutions C and B to react and deposit in situ on the lithium-rich material. surface;

[0041] (4) Aging the solution for 3 hours under stirring at room temperature, then evaporating to dryness...

Embodiment 3

[0043] Embodiment 3: A kind of modification method of phosphate-coated lithium-rich manganese-based positive electrode material, comprises the following steps:

[0044] (1) Evenly disperse 0.5 g of the prepared lithium-rich manganese-based positive electrode material in 70 mL of a mixed solution of deionized water and ethanol with a volume ratio of 1:1, and add 0.5 g of surfactant DTAB to obtain solution A;

[0045] (2) 1.3539g gadolinium nitrate and 0.2699g diammonium hydrogen phosphate were dissolved in 100mL deionized water respectively to make solutions B and C;

[0046] (3) Add solutions B and C dropwise to the dispersion of the lithium-rich manganese-based positive electrode material successively under stirring at room temperature, adjust the pH value of the solution to 10, and allow the solutions C and B to react and deposit in situ on the lithium-rich material. surface;

[0047] (4) Aging the solution for 3 hours under stirring at room temperature, then evaporating to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com