Film-base electric device

A technology of electricity and devices, which is applied in the field of thin film-based electrical devices, can solve problems such as limiting electronic and material transmission of electrical devices, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

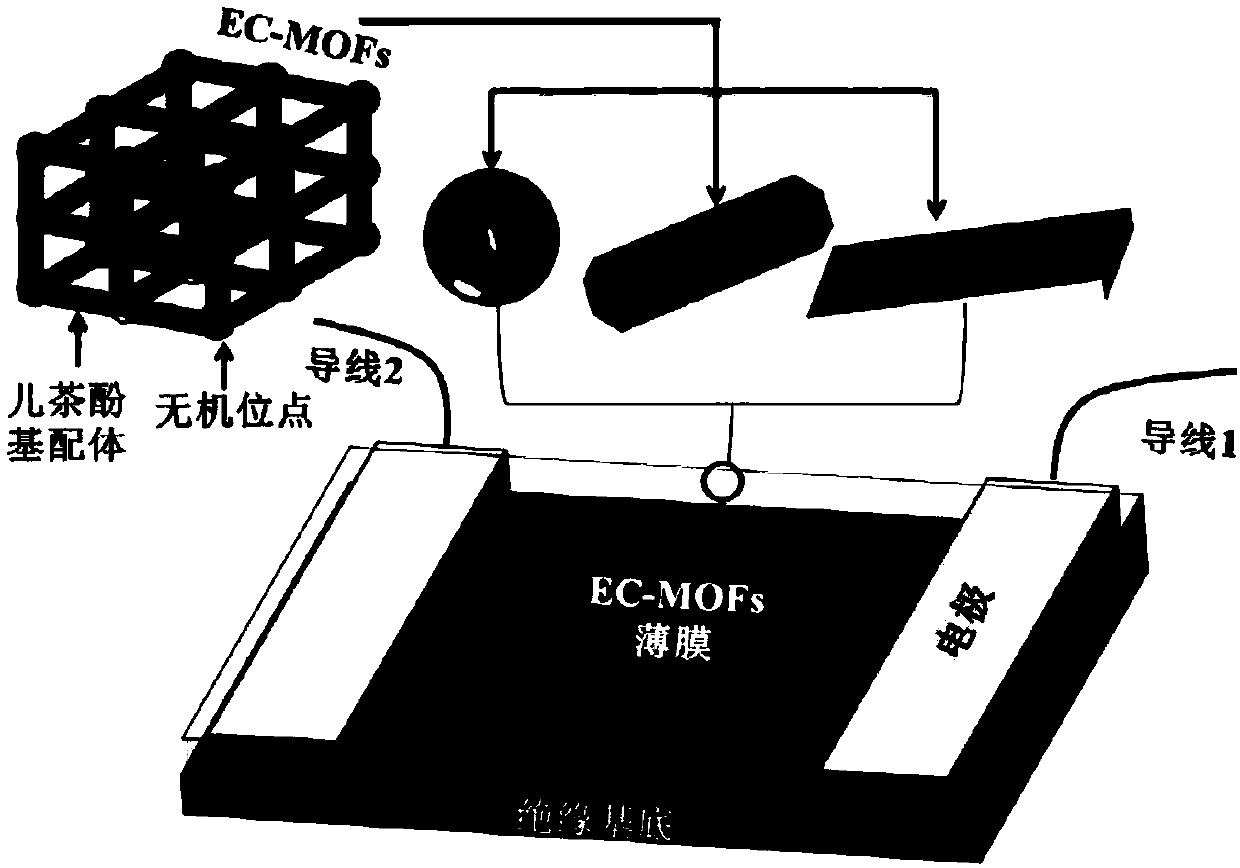

[0054] Such as figure 1 The electrical devices shown are, from bottom to top, an insulating substrate, two electrodes (including two wires) and an EC-MOFs thin film. And, at the top are the three forms of the basic constituent units of MOFs films, which are 0-dimensional particles, one-dimensional wires / rods and two-dimensional sheets, and the upper left corner shows the schematic diagram of the MOFs structure.

[0055] The specific preparation method of the electrical device is as follows:

[0056] The substrate was first ultrasonically washed in a solvent of acetone:isopropanol:water with a volume ratio of 1:1:1 for half an hour, and then ultrasonically washed with deionized water for 10 minutes. Then rinse with ethanol and blow dry with nitrogen. Thermally evaporated on the substrate with the aid of a stainless steel mask such as figure 1 The Au electrode shown, and two noble metal wires are drawn out with the help of conductive gold glue, and connected to the test instr...

Embodiment 2

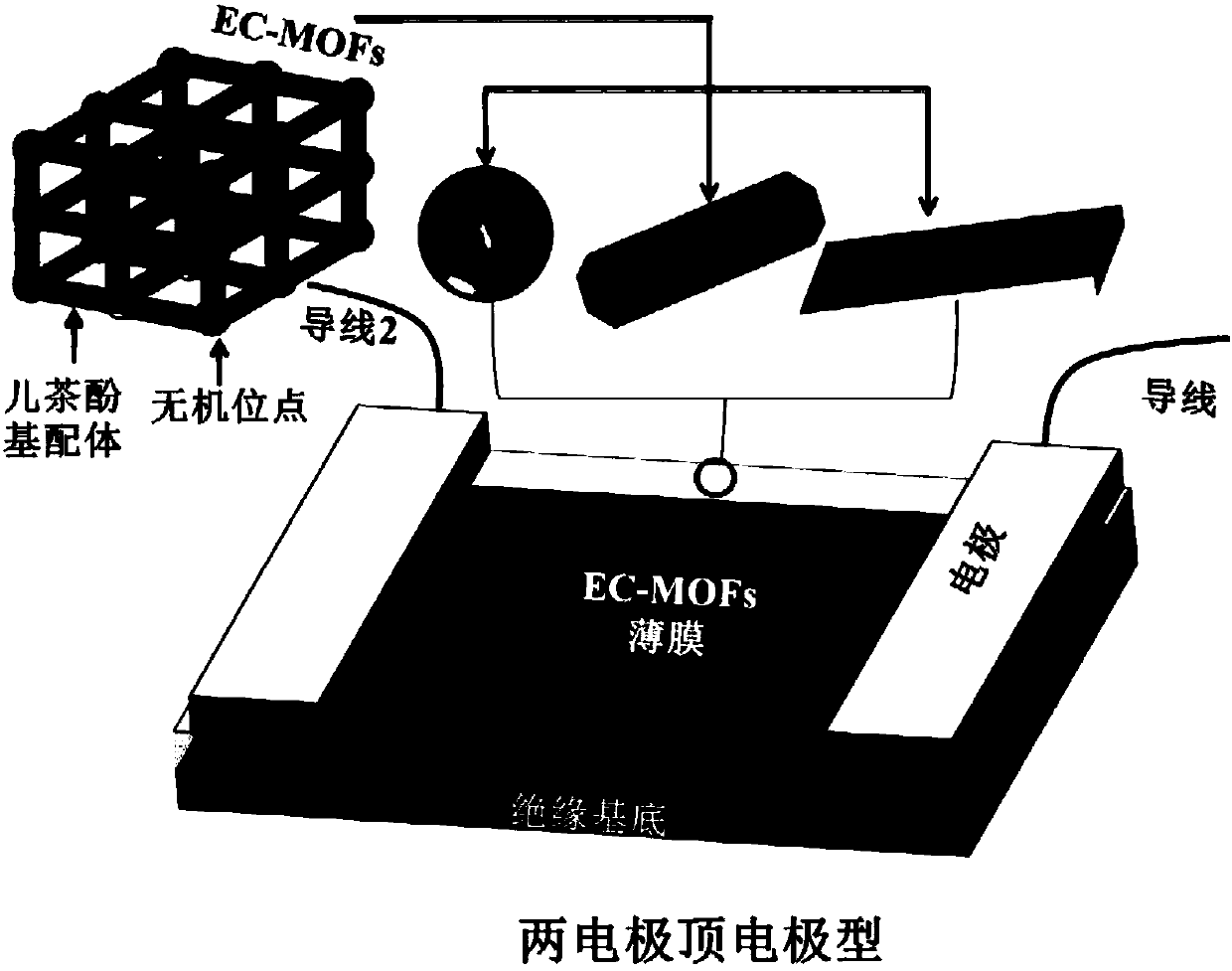

[0060] Such as figure 2 The electrical devices shown are, from bottom to top, an insulating substrate, an EC-MOFs film, and two electrodes (including two wires). And, at the top are the three forms of the basic constituent units of MOFs films, which are 0-dimensional particles, one-dimensional wires / rods and two-dimensional sheets, and the upper left corner shows the schematic diagram of the MOFs structure.

[0061] The specific preparation method of the electrical device is as follows:

[0062] The substrate was first ultrasonically washed in a solvent of acetone:isopropanol:water with a volume ratio of 1:1:1 for half an hour, and then ultrasonically washed with deionized water for 10 minutes. Then rinse with ethanol and blow dry with nitrogen. Prepare 0.1mol / L copper acetate solution and 0.1mol / L methanol solution of HHTP organic ligand, fix the above substrate on a substrate, first take 3mL copper acetate solution, spray for about 20 seconds, and then use 4mL Rinse with...

Embodiment 3

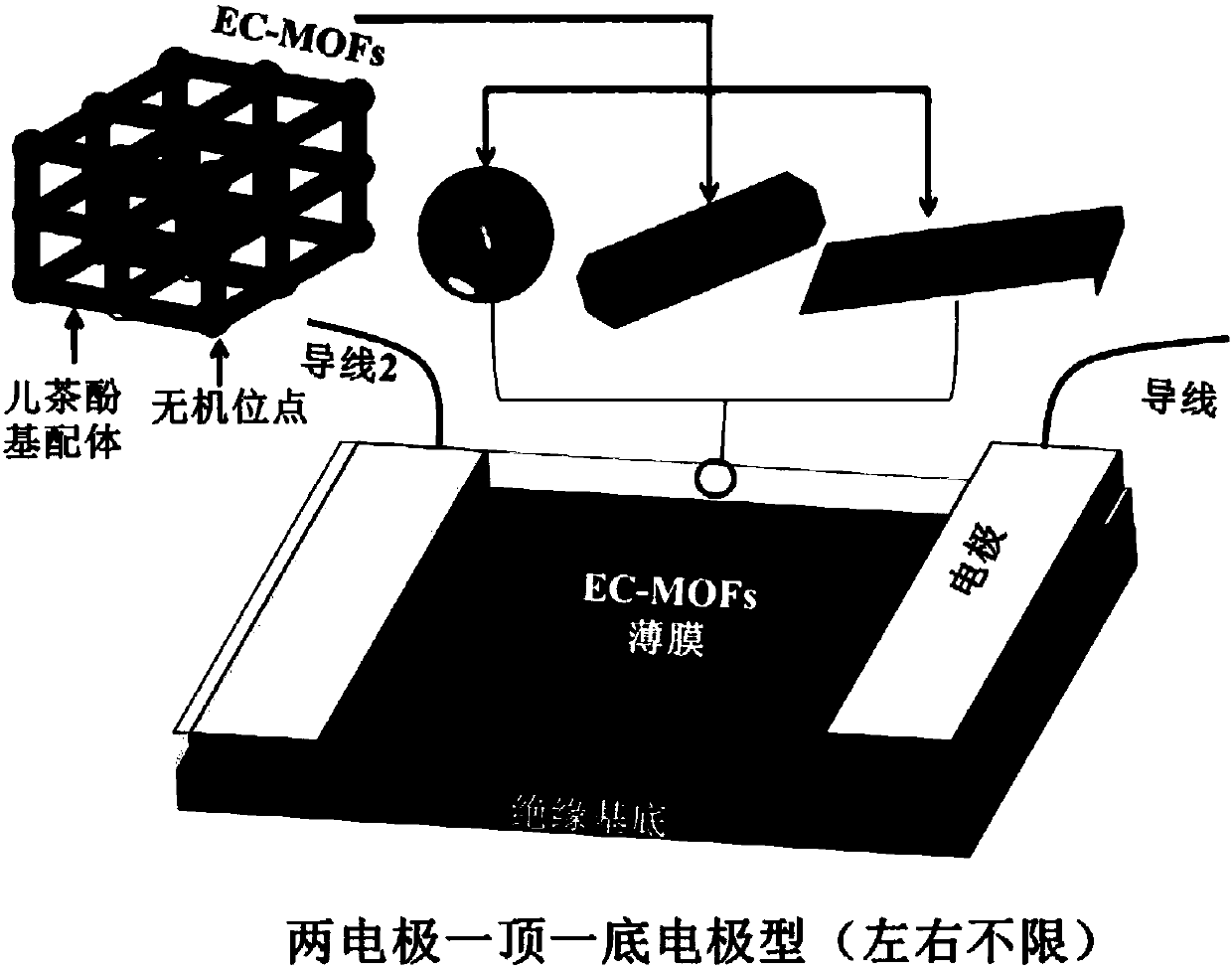

[0064] Such as image 3 The electrical devices shown are, from bottom to top, an insulating substrate, a first electrode (containing a wire), an EC-MOFs thin film, and a second electrode (containing a wire). And, at the top are the three forms of the basic constituent units of MOFs films, which are 0-dimensional particles, one-dimensional wires / rods and two-dimensional sheets, and the upper left corner shows the schematic diagram of the MOFs structure.

[0065] The specific preparation method of the electrical device is as follows:

[0066] The substrate was first ultrasonically washed in a solvent of acetone:isopropanol:water with a volume ratio of 1:1:1 for half an hour, and then ultrasonically washed with deionized water for 10 minutes. Then rinse with ethanol and blow dry with nitrogen. Thermally evaporated on the substrate with the aid of a stainless steel mask such as image 3 The single Au electrode is shown, and a noble metal wire is drawn out with the help of condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com