Lining film for vacuum chamber wall of sputtering equipment and preparation method

A technology of sputtering equipment and lining film, applied in the field of sputtering equipment, can solve the problems of non-seamless attachment, polluted support, environmental pollution, etc., and achieve the effects of prolonging service life, improving utilization rate and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

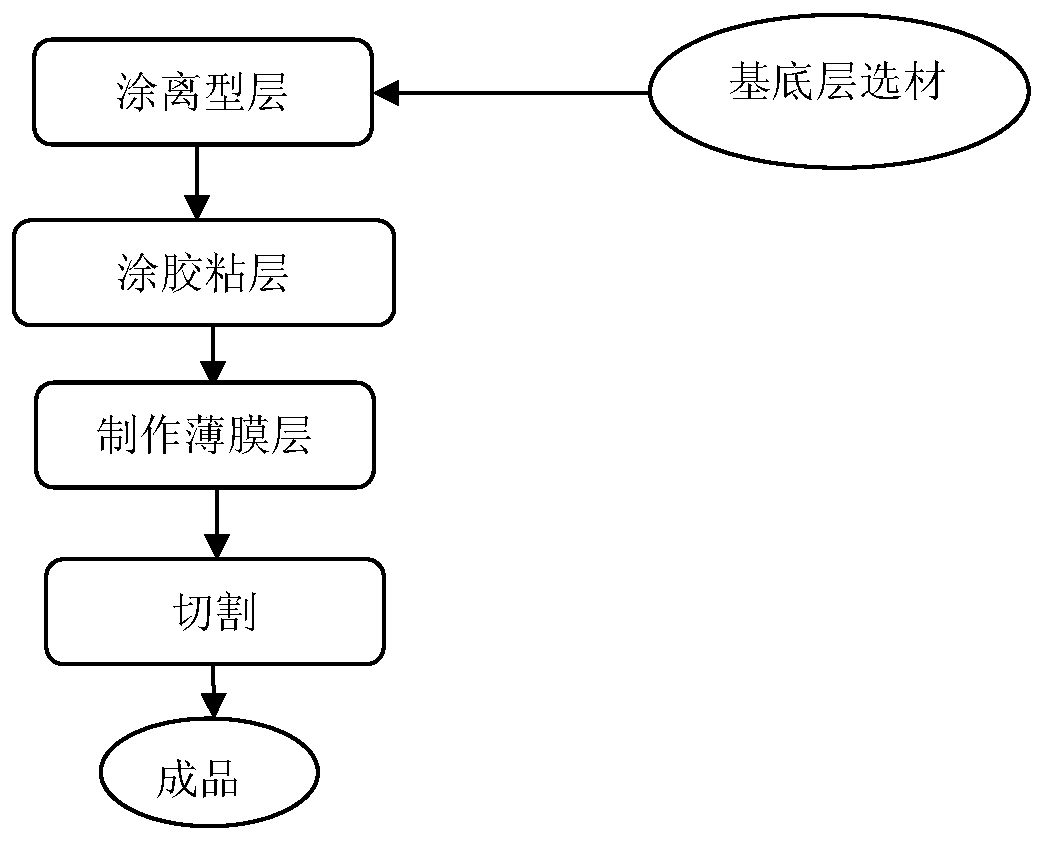

[0030] A method for preparing a lining film for a vacuum chamber wall of a sputtering device. The lining film is composed of a base layer, a release layer, an adhesive layer, and a thin film layer. The release layer and the adhesive layer And the film layer is sequentially formed on the base layer, including the following steps:

[0031] (1) The step of coating the release layer: scrape the release layer paint on the base layer, and obtain the release layer after drying. The drying temperature is 80℃-120℃, and the drying time is 2-5 minutes;

[0032] (2) Steps of applying adhesive layer: scrape the adhesive layer paint on the release layer;

[0033] (3) Steps of making the film layer: After coating the degradable polymer material solution on the adhesive layer, evenly spread the chitin fiber, the drying temperature is 120℃-180℃, and the drying time is 2-5 minutes. The film layer obtained after drying is a semi-finished product;

[0034] (4) Cutting and forming step: separating the le...

Embodiment 2

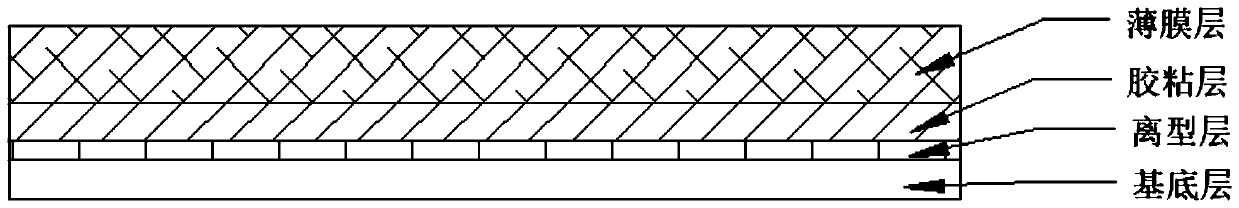

[0042] Attached below figure 1 The present invention is further explained. But it does not limit the content of the present invention.

[0043] Attached figure 1 It is a schematic cross-sectional view of the lining film used in the vacuum chamber wall of the sputtering equipment.

[0044] The base layer (10) is a conventional polymer film, which can be polyester (PET), polyethylene (PE), polyvinyl chloride (PVC), polycarbonate (PC), polyimide (PI), etc. , The thickness can be between 3-300 microns. Preferably, it is a polyester (PET) film about 10 microns thick.

[0045] The base layer (10) is coated with a release layer (20) with a thickness of about 0.5-5 microns. The release layer contains emulsified wax or silicone. The most effective one is silicone, and it can also contain A certain amount of resin, such as PU resin.

[0046] The release layer (20) is coated with an adhesive layer (30) with a thickness of about 0.5-5 microns. The adhesive layer contains at least one of acryli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com