Polyaryl ether sulfone composite material and application thereof

A composite material, polyaryl ether sulfone technology, applied in the field of polymer material modification, can solve the problems of poor dimensional stability and creep performance, poor life, difficult to use for a long time, etc., to achieve the effect of improving sensory experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

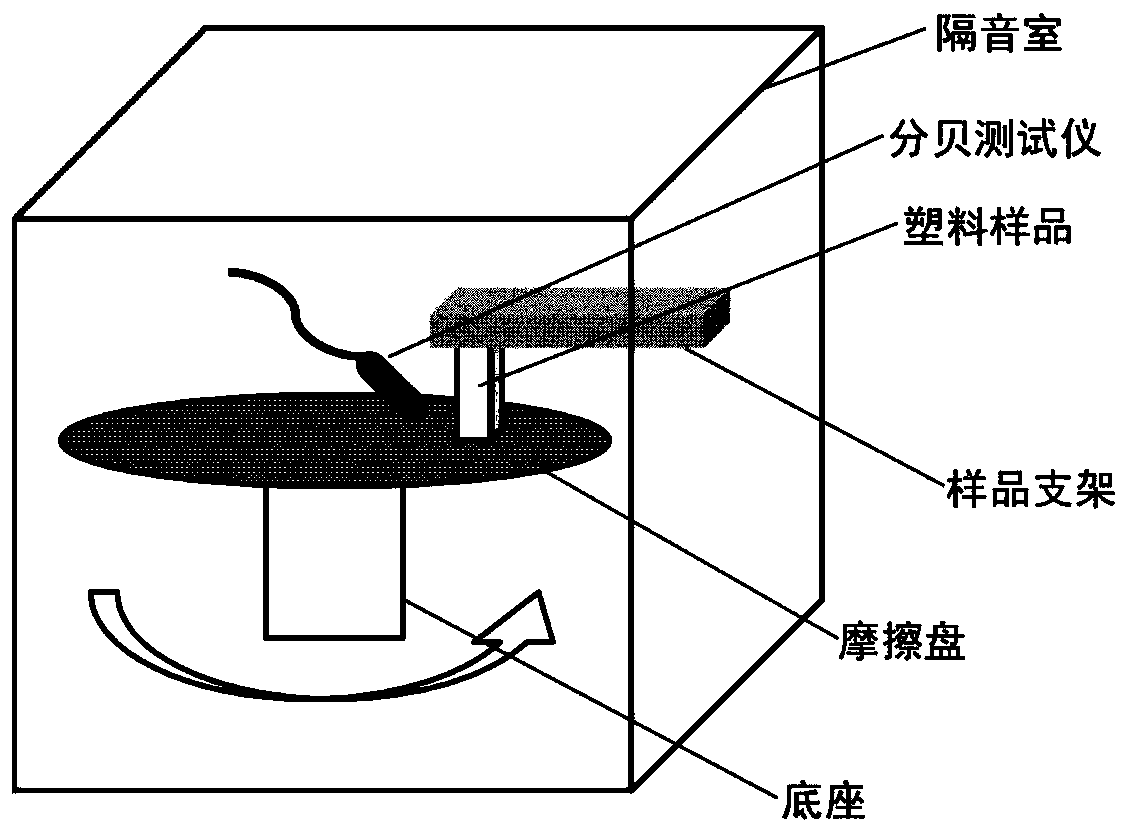

Image

Examples

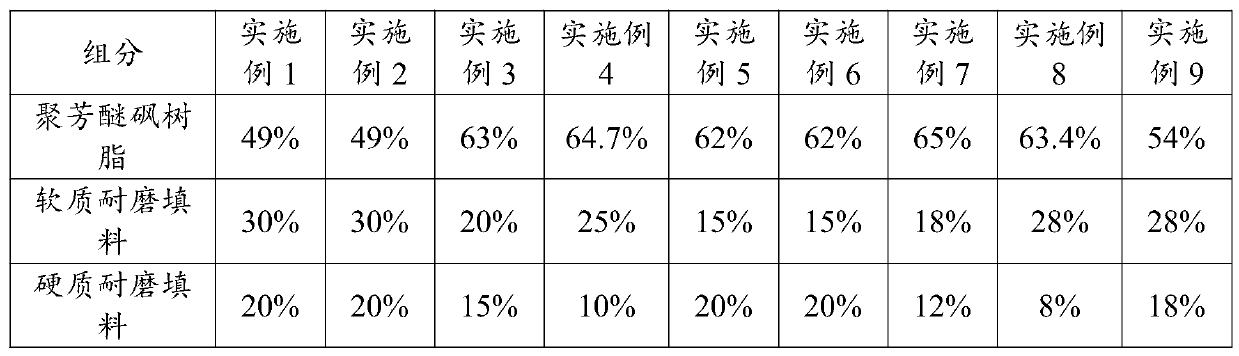

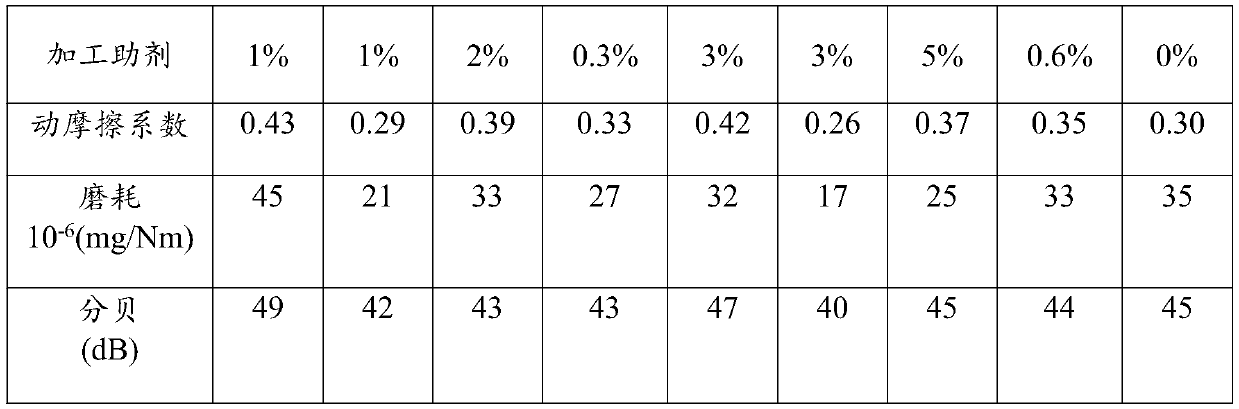

Embodiment 1

[0027] The materials are weighed in parts by weight, wherein the polyarylethersulfone resin is selected from 100% PPSU, the soft wear-resistant filler is selected from graphite, and the hard wear-resistant filler is selected from potassium titanate whiskers; the weighed materials and processing aids are put into Stir in a high-speed mixer for 3 minutes to mix evenly. After drying at 100°C for 2 hours, melt and extrude to granulate through a screw extruder. Extrusion temperature: 320°C, speed: 200rpm.

Embodiment 2

[0029] Take the material by parts by weight, wherein the polyaryl ether sulfone resin is selected PPSU:PES=50%:50%, the soft wear-resistant filler is selected graphite, and the hard wear-resistant filler is selected potassium titanate whisker; The materials and processing aids were put into a high-speed mixer and stirred for 3 minutes to mix evenly. After drying at 100°C for 2 hours, they were melt-extruded and granulated through a screw extruder. Extrusion temperature: 320°C, speed: 200rpm.

Embodiment 3

[0031] The materials are weighed in parts by weight, wherein the polyaryl ether sulfone resin is selected from PPSU:PES:PSU=70%:20%:10%, the soft wear-resistant filler is selected from polytetrafluoroethylene, and the hard wear-resistant filler is selected from silicon carbide; Put the weighed material and processing aid into a high-speed mixer and stir for 5 minutes to mix evenly. After drying at 120°C for 3 hours, melt and extrude the pellets through a screw extruder. Extrusion temperature: 300°C, speed: 300rpm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| noise | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com