Preparation method and application of transition metal oxide/graphitized mesocarbon microbead composite material

A technology of mesocarbon microspheres and transition metals, applied in electrochemical generators, electrical components, battery electrodes, etc., can solve the problems of material detachment and lower battery cycle performance, and achieve increased conductivity, restrained volume expansion effect, The effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of nickel oxide / graphitized mesocarbon microsphere composite material, comprising the following steps:

[0038] (1) Surface oxidation treatment of graphitized mesocarbon microspheres; the graphitized mesocarbon microspheres were purchased from Shenzhen Betterray New Energy Materials Co., Ltd.;

[0039] (1-1) Under ice-water bath, add 200mL of 98% concentrated sulfuric acid to the round bottom flask, add graphitized mesophase carbon microspheres 10g and 2.5g sodium nitrate successively under mechanical stirring, then add 10g permanganate Potassium, continue stirring reaction 2h;

[0040] (1-2) Raise the temperature of the water bath to 45°C. Continue stirring for 3h;

[0041] (1-3) Under stirring conditions, add 400mL of 80°C deionized water, adjust the temperature until the temperature of the water bath is adjusted to 95°C, add 150mL of 10%wt hydrogen peroxide, and continue stirring for 3h;

[0042] (1-4) Wash the product with 5%wt dilute hydroch...

Embodiment 2

[0046] A preparation method of iron oxide / graphitized mesocarbon microsphere composite material, comprising the following steps:

[0047] (1) Carry out surface oxidation treatment with graphitized mesocarbon microspheres, step is the same as step (1) in embodiment 1;

[0048](2) Dissolve 0.5 g of ferric chloride in 25 mL of deionized water, place it in a round bottom flask, add 8 g of surface oxidized graphitized mesophase carbon microspheres, stir for 10 min, add ammonia water dropwise to pH=12, and continue stirring 10h, the reaction is over; use deionized water to wash to neutrality, filter with suction, and dry to obtain a precursor, and prepare a precursor;

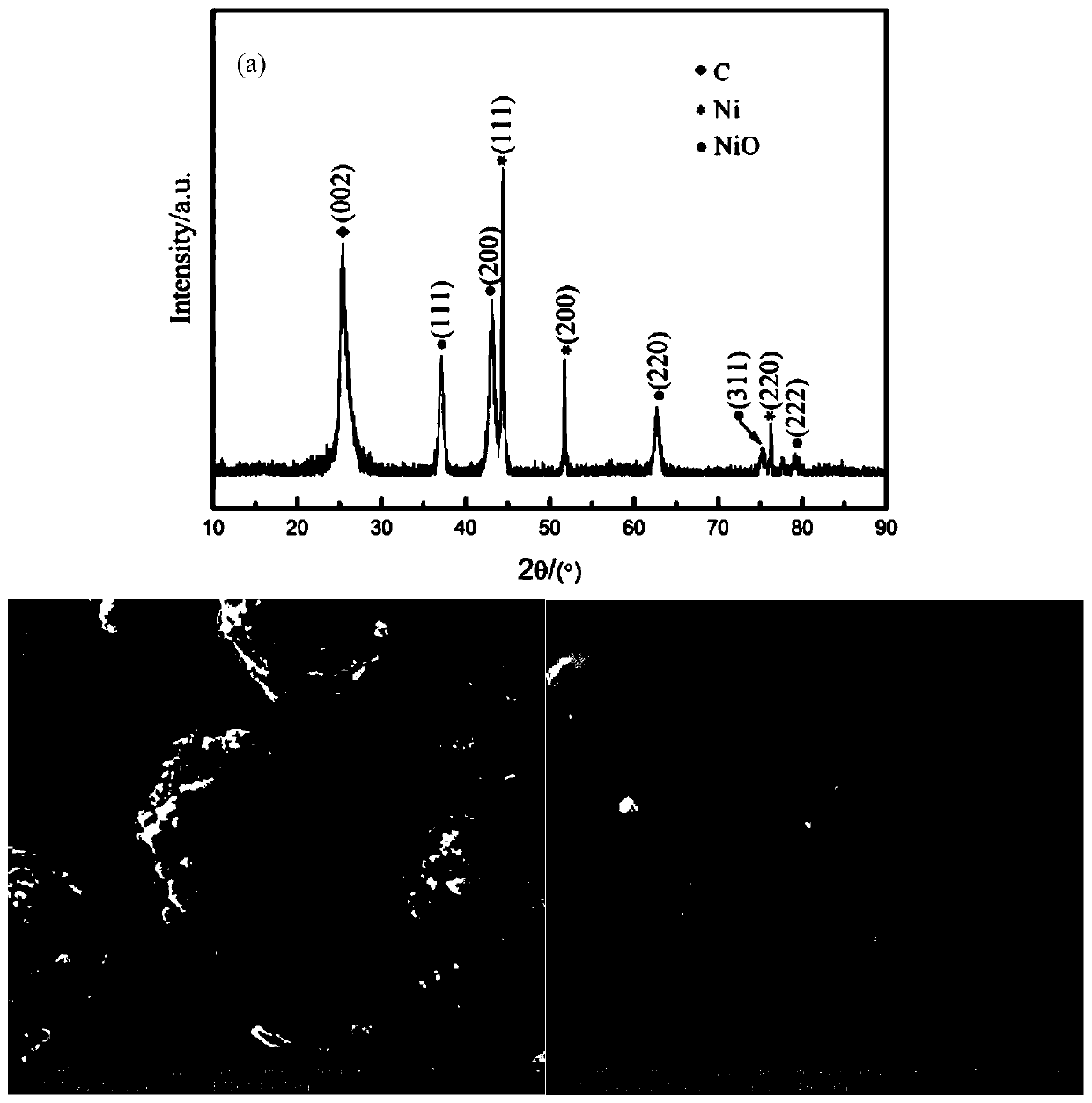

[0049] (3) Put it in a tube furnace, raise the temperature from room temperature to 500° C. at a heating rate of 2° C. / min under the protection of an inert atmosphere, and keep it for 1 hour to obtain the iron oxide / graphitized mesocarbon microsphere composite material. Figure 5 XRD and SEM images of iron oxide / gra...

Embodiment 3

[0051] A preparation method of iron oxide / graphitized mesocarbon microsphere composite material, comprising the following steps:

[0052] (1) carrying out surface oxidation treatment with graphitized mesocarbon microspheres, step is the same as step (1) in embodiment 1;

[0053] (2) Take 0.5g of manganese chloride and dissolve it in 25mL of deionized water, put it in a round bottom flask, add 8g of surface oxidized graphitized mesophase carbon microspheres, stir for 20min, add ammonia water dropwise to PH=12, and continue stirring 24h, the reaction is over; use deionized water to wash to neutrality, filter with suction, and dry to obtain the precursor, and prepare the precursor;

[0054] (3) Put it in a tube furnace, raise the temperature from room temperature to 500° C. at a heating rate of 2° C. / min under the protection of an inert atmosphere, and keep it for 1 hour to obtain the manganese monoxide / graphitized mesocarbon microsphere composite material. Figure 7 XRD and SEM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com