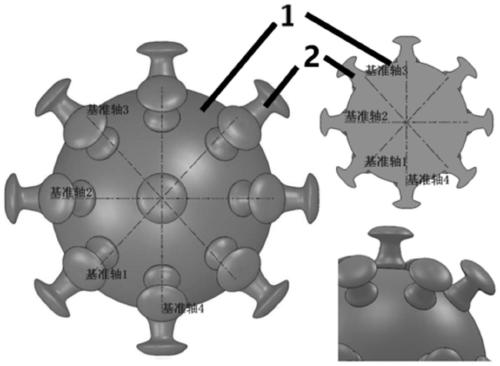

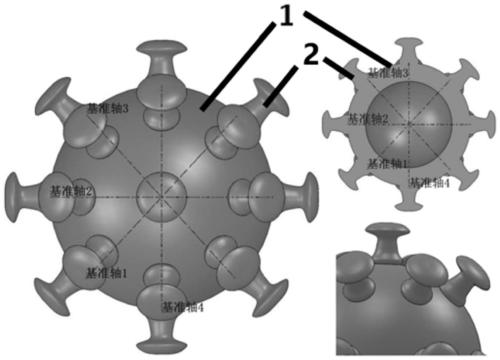

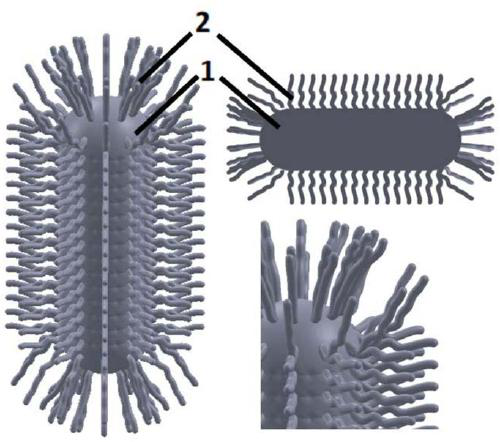

Bionic concrete coarse aggregate based on photo-curing 3D (three-dimensional) printing, preparation method of aggregate and application of aggregate

A 3D printing, coarse aggregate technology, applied in manufacturing, additive processing, etc., can solve the problems of lack of centralized management and advanced production mode, inability to form large-scale industrial mining, and inability to guarantee the quality of aggregate production. Fast printing speed, accurate molding, and increasing the effect of mechanical bite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] When 3D printing, set the number of printing layers of the base layer to 4 layers, the illumination time of the base layer is 35s, the illumination time of other layers is 8s, the luminous flux is 375lm, and the bionic concrete coarse aggregate of 12.5mm is printed. Take the bionic concrete coarse aggregate after printing, clean it with analytical pure alcohol, remove the support, use a 405nm wavelength LED ultraviolet shadowless lamp with a power of 200W, and irradiate for 1h. Take limestone coarse aggregate with the same particle size, wash and dry. Weigh water, cement, and standard sand according to the mass ratio of 1:2:6, and form a 40mm*40mm*40mm cubic test block after fully stirring, and press the aggregate into the center of different cubic test blocks. The curing temperature is 20±2°C, and the curing humidity is above 90%. After curing for 28 days, the average compressive strengths of the single aggregate mortar test blocks of 3D printed bionic coarse aggregat...

Embodiment 2

[0042] When 3D printing, set the printing layer of the base layer to 3 layers, the illumination time of the base layer is 30s, the illumination time of other layers is 9s, the luminous flux is 400lm, and the bionic concrete coarse aggregate of 4.75mm is printed. Take the bionic concrete coarse aggregate after printing, clean it with analytical pure alcohol, remove the support, use a 405nm wavelength LED ultraviolet shadowless lamp with a power of 200W, and irradiate for 1h. Take limestone coarse aggregate with the same particle size, wash and dry. Weigh water, cement, and standard sand according to the mass ratio of 1:2:6, and form a 20mm*20mm*20mm cubic test block after fully stirring, and press the aggregate into the center of different cubic test blocks. The curing temperature is 20±2°C, and the curing humidity is above 90%. After 28 days of curing, the average compressive strength of the single aggregate mortar test blocks of 3D printed bionic coarse aggregate and limesto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Specific strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com