High-frequency resin prepolymer and high-frequency resin combination, prepreg, laminated board and interlayer insulating membrane prepared with same

A resin composition and prepreg technology, applied in synthetic resin layered products, chemical instruments and methods, layered products, etc., can solve the problems of high water absorption of materials, reduce the packing density, strengthen the self-extinguishing property, and solve the problems of high water absorption. insoluble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] According to the method in the synthesis example, react at 60°C for 120 minutes to prepare 30 g of prepolymers of cage-type silsesquioxane with amino groups: carboxyl polyarylether ketone = 10:50, add appropriate amount of N, N-dimethyl ethyl Amide is dissolved; after the POSS modified polyaryletherketone prepolymer is completely dissolved, add 30g of phosphorus-containing epoxy resin (XZ92530, Dow Chemical), 30g of phenolic curing agent (PF-8011, Shandong Shengquan), 10g of phosphorus-containing Phenolic (XZ92741, Dow Chemical), 0.01 g of 2-ethyl-4 methylimidazole, 40 g of spherical silica, and an appropriate amount of butanone solvent were stirred and mixed evenly to obtain a glue solution with a solid content of 60%.

[0061] The glue solution was dipped and coated on E glass fiber cloth (2116, unit weight 104g / m2), and baked in an oven at 135°C for 5min to obtain a prepreg with a resin content of 50%.

[0062] The prepared prepreg with a resin content of 50% was pla...

Embodiment 2

[0065] According to the method in the synthesis example, react at 60°C for 120 minutes to prepare 30 g of prepolymers of cage-type silsesquioxane with amino groups: phenylcarboxypolyaryletherketone = 10:80, add appropriate amount of N, N-dimethyl Acetamide is dissolved; after the POSS modified polyaryletherketone prepolymer is completely dissolved, add 30g of naphthalene-containing ring-type epoxy resin (NC-7300, Nippon Kayaku), 25g of phenolic curing agent (PF-8011, Shandong Shengquan ), 15g phosphorus-containing phenolic aldehyde (XZ92741, Dow Chemical), 0.01g 2-ethyl-4 methylimidazole, 40g spherical silica, an appropriate amount of methyl ethyl ketone solvent, stir and mix evenly to obtain a glue solution with a solid content of 60%.

[0066] The preparation methods of the prepreg and the copper-clad laminate are the same as in the first embodiment.

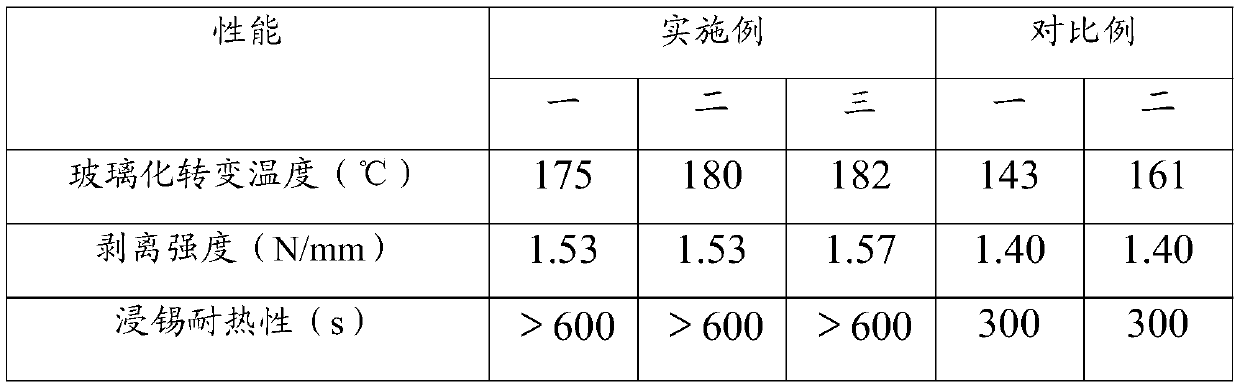

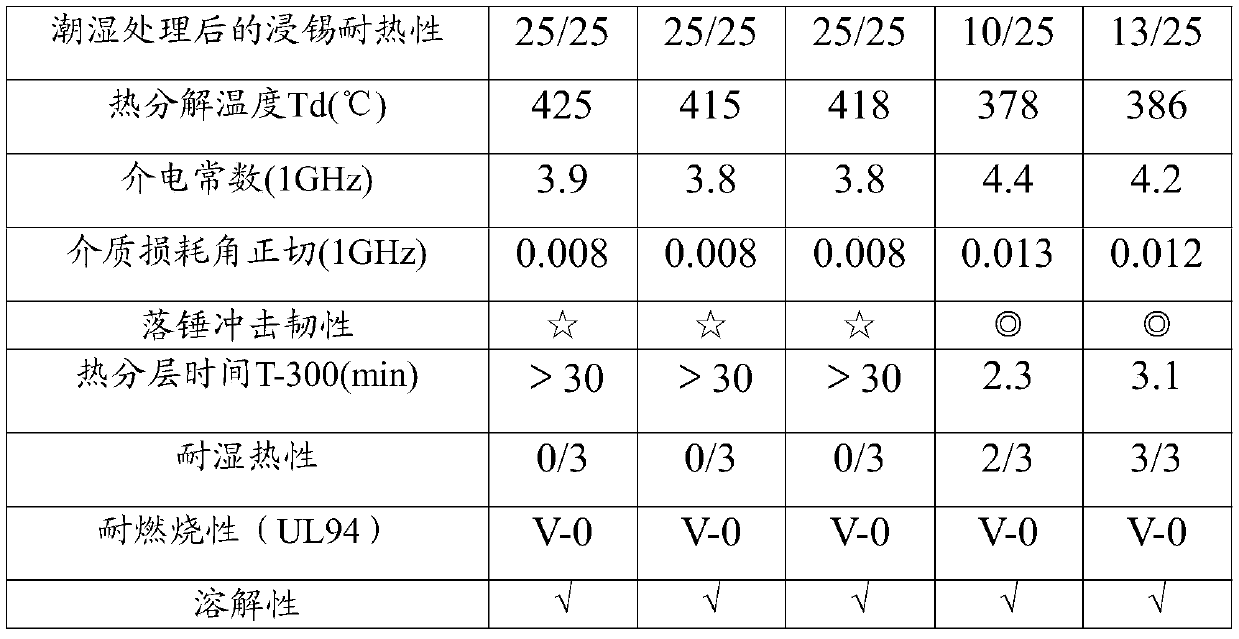

[0067] The properties of the obtained copper-clad laminates are shown in Table 1.

Embodiment 3

[0069] According to the method in the synthesis example, react at 60°C for 120 minutes to prepare 30 g of a prepolymer of cage silsesquioxane with epoxy groups: carboxyl polyarylether ketone = 10:40, add appropriate amount of N, N-dimethyl Acetamide was dissolved; after the POSS modified polyaryletherketone prepolymer was completely dissolved, 30g of dicyclopentadiene epoxy resin (XD-1000, Nippon Kayaku), 22g of phenolic curing agent (PF-8011, Shandong Holy Spring), 18g phosphorus-containing phenolic aldehyde (XZ92741, Dow Chemical), 0.01g 2-ethyl-4 methylimidazole, 40g spherical silicon dioxide, an appropriate amount of methyl ethyl ketone solvent, stir and mix to obtain a glue with a solid content of 60% liquid.

[0070] The preparation methods of the prepreg and the copper-clad laminate are the same as in the first embodiment.

[0071] The properties of the obtained copper-clad laminates are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com