Method for utilizing two-stage continuous operation hot-alkali decomposition technology for processing rare earth ore concentrate

A technology of rare earth concentrate and hot alkali, which is applied in hot alkali decomposition treatment of rare earth concentrate, the treatment of rare earth concentrate, and the field of improving the decomposition of rare earth concentrate, which can solve the problems of shortening processing time, lowering processing temperature, and low operating safety , to achieve the effect of reducing process cost, improving efficiency, and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

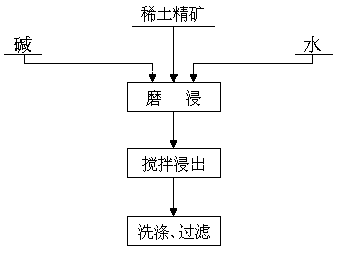

[0034] In domestic professional equipment, -80 mesh mixed rare earth concentrate (content REO37%) is calculated according to the weight ratio of mixed rare earth concentrate:, alkali = 1:1.2, and 45% lye is prepared in professional equipment. Take lye: mixed rare earth concentrate = 2:1 ratio; transport the lye to professional equipment for high-speed stirring, and slowly add mixed rare earth concentrate to the professional equipment, and heat the slurry through an external heating device To 80-120 ℃, pumped into the grinding and soaking machine while grinding and soaking, the speed of the milling and soaking machine is 2000r / min, the medium of the milling and soaking machine is zirconia, and the slurry enters the milling and soaking machine from one end of the milling and soaking machine; the slurry after grinding and soaking It is directly transported from the outlet of the grinding and soaking machine to the stirring reaction tank, and the temperature is raised to 120-130 ° ...

example 2

[0036] In the domestic professional equipment, the -100 mesh monazite concentrate (content REO51%) is calculated according to the weight ratio of monazite:alkali=1:1.4, and 55% lye is prepared in the professional equipment. Take lye: monazite = 2.5:1 and weigh it; transport the lye to professional equipment for high-speed stirring, then slowly add monazite into the professional equipment, and heat the slurry to 70-130°C through an external heating device. Pump into the grinding and soaking machine for grinding and dipping. The speed of the milling and soaking machine is 2200r / min. The medium of the milling and soaking machine is zirconia. The slurry enters the milling and soaking machine from one end of the milling and soaking machine; The outlet is transported to the stirring reaction tank, and the temperature is raised to 130-140 ° C; after the heat preservation and stirring reaction is completed for 4 hours, the alkali cake is obtained by washing and filtering. Subsequent h...

example 3

[0038] In domestic professional equipment, -60 mesh bastnaesite concentrate (content REO45%) is calculated according to the weight ratio of bastnaesite concentrate: alkali = 1:1.3, and 50% lye is prepared in professional equipment. Take lye: mixed rare earth concentrate = 2.3:1 ratio weight; transport lye to professional equipment for high-speed stirring, bastnaesite concentrate is slowly added to the lye in the professional equipment, through the external heating device Heat the slurry to 90-110°C, pump it into the milling and soaking machine while grinding and soaking, the speed of the milling and soaking machine is 2100r / min, the medium of the milling and soaking machine is alumina, and the slurry enters the milling and soaking machine from one end of the milling and soaking machine; The final slurry is directly transported from the outlet of the grinding and soaking machine to the stirring reaction tank, and the temperature is raised to 130-140°C; after 4 hours of heat pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com