Silicon wafer waste powder solid waste treatment method and product thereof

A processing method and powder technology, applied in cement production and other directions, can solve problems such as not very high purity, no silica fume waste found, and achieve the effects of simple process, low cost, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

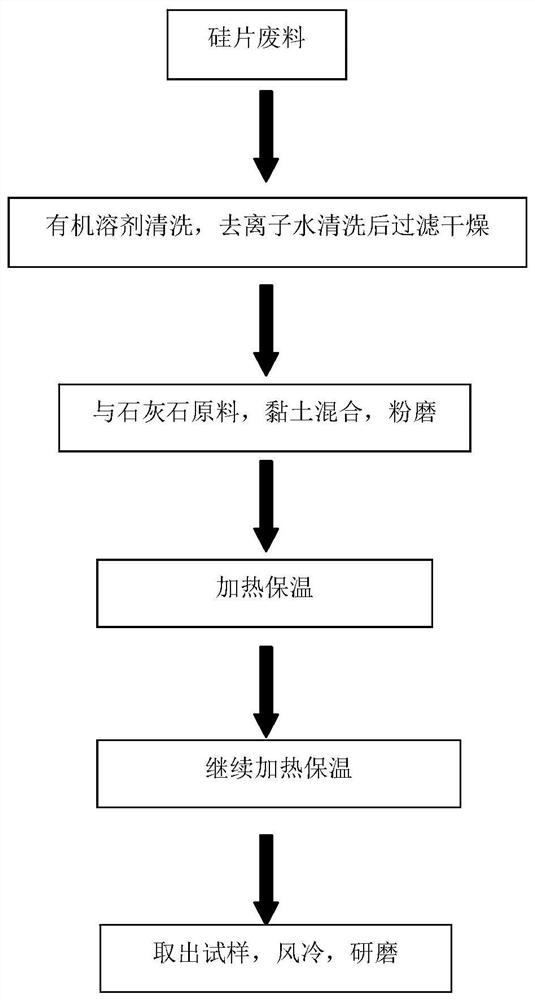

Method used

Image

Examples

Embodiment 1

[0025] The silicon wafer waste powder was soaked in a mixed solution of ethanol and acetone with a volume ratio of 1:1, stirred for 20 min, filtered and rinsed with deionized water, and dried at 100 °C. Mix limestone powder, dried silicon wafer waste, and clay at a mass ratio of 1.4:0.1:0.3. After mixing evenly, put it into a reaction furnace and heat it. The heating rate is 10°C / min, heated to 800°C, and kept for 2 hours. , and then continue to heat to 1450 ° C, heat preservation for 2 hours. The sample was taken out, air-cooled to room temperature, and ground through a 80 μm square hole sieve to obtain cement clinker. Add water and stir, the water-cement ratio is 0.44, pour the cement slurry into a 4×4×16cm triple mold, vibrate and form, standard curing for 3 days, measure its compressive strength according to GB175-2017 after 28 days, and use glycerin— The ethanol method is used to determine the free calcium oxide content in cement according to GB / T12573, and the results a...

Embodiment 2

[0027] The silicon wafer waste powder was soaked in a mixed solution of ethanol and acetone with a volume ratio of 1:1, stirred for 20 min, filtered and rinsed with deionized water, and dried at 100 °C. Mix limestone powder, dried silicon chip waste, and clay at a mass ratio of 1.4:0.2:0.2. After mixing evenly, put it into a reaction furnace for heating. The heating rate is 10°C / min, heated to 900°C, and kept for 2 hours. . Then continue heating to 1450°C and keep the temperature for 2 hours. The sample was taken out, air-cooled to room temperature, and ground through a 80 μm square hole sieve to obtain cement clinker. Add water and stir, the water-cement ratio is 0.44, pour the cement slurry into a 4×4×16cm triple mold, vibrate and form, standard curing for 3 days, measure its compressive strength according to GB175-2017 after 28 days, and use glycerin— The ethanol method is used to determine the free calcium oxide content in cement according to GB / T12573, and the results a...

Embodiment 3

[0029] The silicon wafer waste powder was soaked in a mixed solution of ethanol and acetone with a volume ratio of 1:1, stirred for 20 min, filtered and rinsed with deionized water, and dried at 100 °C. Mix limestone powder, dried silicon wafer waste, and clay at a mass ratio of 1.4:0.15:0.25. After mixing evenly, put it into a reaction furnace and heat it. The heating rate is 10°C / min, heated to 850°C, and kept for 2 hours. . Then continue heating to 1450°C and keep the temperature for 2 hours. The sample was taken out, air-cooled to room temperature, and ground through a 80 μm square hole sieve to obtain cement clinker. Add water and stir, the water-cement ratio is 0.44, pour the cement slurry into a 4×4×16cm triple mold, vibrate and form, standard curing for 3 days, measure its compressive strength according to GB175-2017 after 28 days, and use glycerin— The ethanol method is used to determine the free calcium oxide content in cement according to GB / T12573, and the result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com