Sodium ion battery negative electrode material and preparation method thereof

A technology of sodium ion battery and negative electrode material, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high cost, difficulty in large-scale industrial production, and low capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

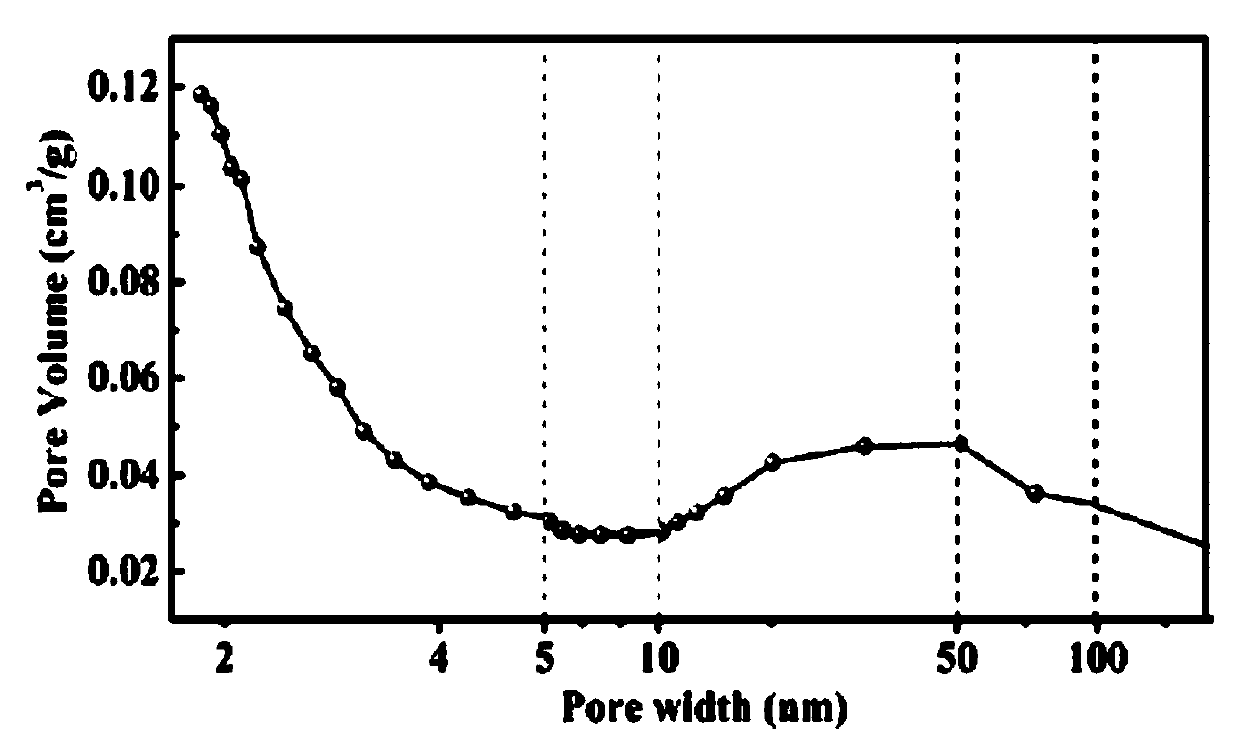

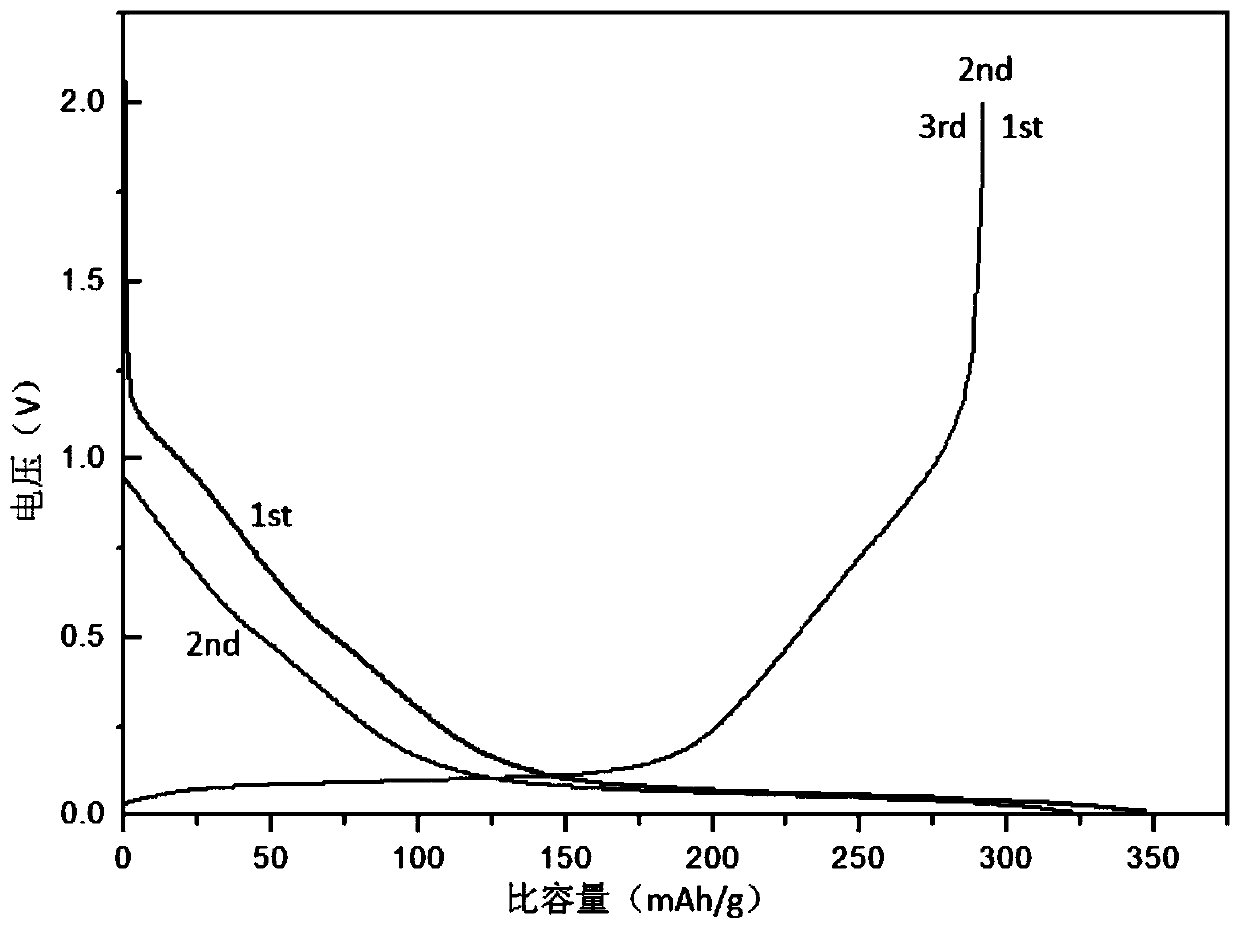

Embodiment 1

[0120]First put 1 kg of anthracite particles in a high-temperature box-type carbonization furnace, with a particle size of about 1 mm. Under an argon atmosphere, raise the temperature to 1200 °C at a heating rate of 5 °C / min, and keep it at 1200 °C for 2 hours; then the obtained product After grinding through a 300-mesh screen, mix it with NaOH powder in a ball mill at a mass ratio of 1:1. The mixing time of the ball mill is 1 hour, and then place the mixed sample in a carbonization furnace again for high-temperature carbonization in an argon atmosphere. , the carbonization temperature is 800°C, the obtained carbonized product is soaked and cleaned with 3M / L hydrochloric acid for 0.5h, and then washed with a certain amount of deionized water until neutral, and then placed in a vacuum oven at 100°C Drying was carried out for 8 hours; another 1 kg of blocky corncobs was taken as a hard carbon precursor, and high-temperature carbonization was also carried out in a high-temperature...

Embodiment 2

[0126] First put 1 kg of anthracite particles in a high-temperature box-type carbonization furnace, with a particle size of about 1 mm. Under an argon atmosphere, raise the temperature to 1400 °C at a heating rate of 5 °C / min, and keep it at 1400 °C for 2 hours; then the obtained product After grinding through a 300-mesh sieve, the mass ratio of 1:1 and CaCO 3 The powders are mixed in a ball mill, and the mixing time of the ball mill is 1h, and then the mixed sample is placed in the carbonization furnace again, and high-temperature carbonization is carried out under an argon atmosphere, and the carbonization temperature is 700°C. Hydrochloric acid soaked and cleaned for 0.5h, then washed with a certain amount of deionized water until neutral, and then dried in a vacuum oven at 100°C for 8 hours; another piece of corn cob 1kg is used as the hard carbon precursor, and the high-temperature carbonization is carried out in the high-temperature carbonization furnace with argon as th...

Embodiment 3

[0129] First put 1 kg of anthracite particles in a high-temperature box-type carbonization furnace, with a particle size of about 1 mm. Under an argon atmosphere, raise the temperature to 1400 °C at a heating rate of 5 °C / min, and keep it at 1400 °C for 2 hours; then the obtained product After grinding through a 300-mesh sieve, mix it with sodium citrate powder in a ball mill at a mass ratio of 1:1. The mixing time of the ball mill is 1 hour, and then place the mixed sample in a carbonization furnace again, and carry out High-temperature carbonization, the carbonization temperature is 700°C, the obtained carbonized product is taken out and soaked and cleaned with 3M / L hydrochloric acid for 0.5h, then washed with a certain amount of deionized water until neutral, and then placed in a vacuum oven at 100°C The drying time was 8 hours under the same conditions; another 1 kg of blocky corncobs was used as a hard carbon precursor, and high-temperature carbonization was also carried o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com