Preparation method of large-area and uniform nanometer dipolymer array

A dimer, large-area technology, applied in nanotechnology for materials and surface science, nanostructure fabrication, nanotechnology, etc., can solve problems such as limited implementation and operation, difficult assembly, limited template assembly, etc., Achieve good stability and repeatability, reduce complexity, and increase stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

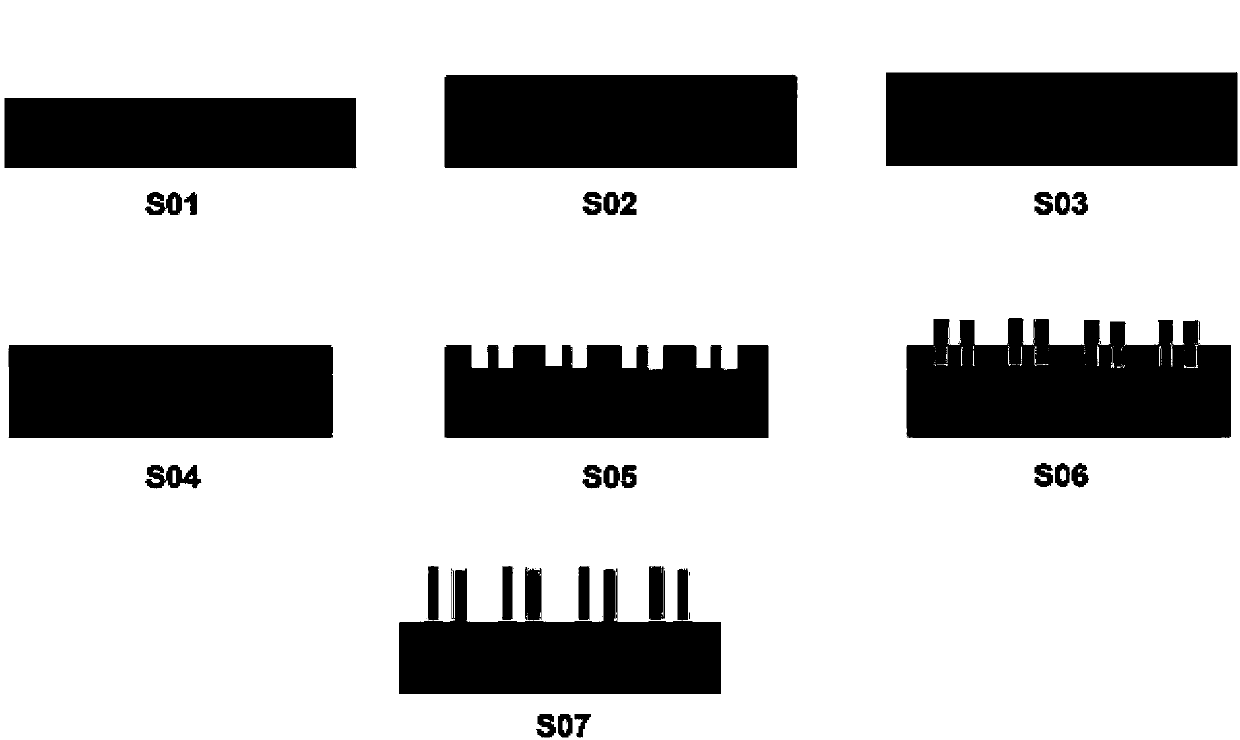

Embodiment 1

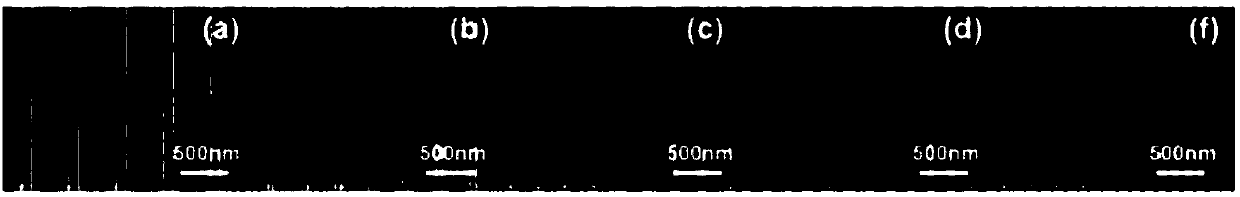

[0050] With reference to the above method, the substrate is a single crystal silicon wafer, the thickness of the stripped photoresist is 150nm, the thickness of the negative photoresist is 500nm, the total laser power is 110mW, and the exposure time is 10s. The obtained photoresist template is as follows: Figure 5 as shown in b. Gold was deposited by electron beam vacuum deposition technology with a thickness of 200nm, and the nanodimer array obtained after removing the template was as follows Figure 5 As shown in f, the array period is 600 nm, and the radius of the obtained petal-shaped nanopillars is about 100 nm. The resulting nanodimer arrays were applied to surface plasmon structures.

Embodiment 2

[0052] With reference to the above method, the substrate is a glass slide, the thickness of the stripped photoresist is 100nm, the thickness of the negative photoresist is 300nm, the total laser power is 110mW, and the exposure time is 15s. The photoresist template obtained is as follows: Figure 5 as shown in c. Deposition of TiO by magnetron sputtering technique 2 , with a thickness of 50nm, the nanodimer array obtained after removing the template is as follows Figure 5 As shown in g, the array period is 600 nm, and the radius of the obtained petal-shaped nanopillars is about 80 nm. The obtained nanodimer arrays are applied in various solar cells, such as fuel-sensitized solar cells, perovskite solar electromagnetics, etc.

Embodiment 3

[0054] With reference to the above method, the substrate is a flexible polyethylene (PE) film, the thickness of the stripped photoresist is 150nm, the thickness of the negative photoresist is 800nm, the total laser power is 110mW, and the exposure time is 20s. Glue template such as Figure 5 shown in d. Ag was deposited by electron beam vacuum deposition technology with a thickness of 400nm, and the nanodimer array obtained after removing the template was as follows: Figure 5 As shown in h, the array period is 600 nm, and the radius of the obtained petal-shaped nanocolumns is about 60 nm. The obtained nanodimer arrays can be used in surface plasmon optics or nano-optics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com