High-COD and high-ammonia nitrogen characteristic sewage bioreactor

A sewage biological, high ammonia-nitrogen technology, applied in the direction of water pollutants, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of low sewage treatment efficiency, large space occupation, BOD5 removal rate, total nitrogen removal rate, etc. Phosphorus removal rate is difficult to meet the ideal requirements and other problems, to achieve the effect of improving air bubble cutting effect and air utilization, increasing effective utilization, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

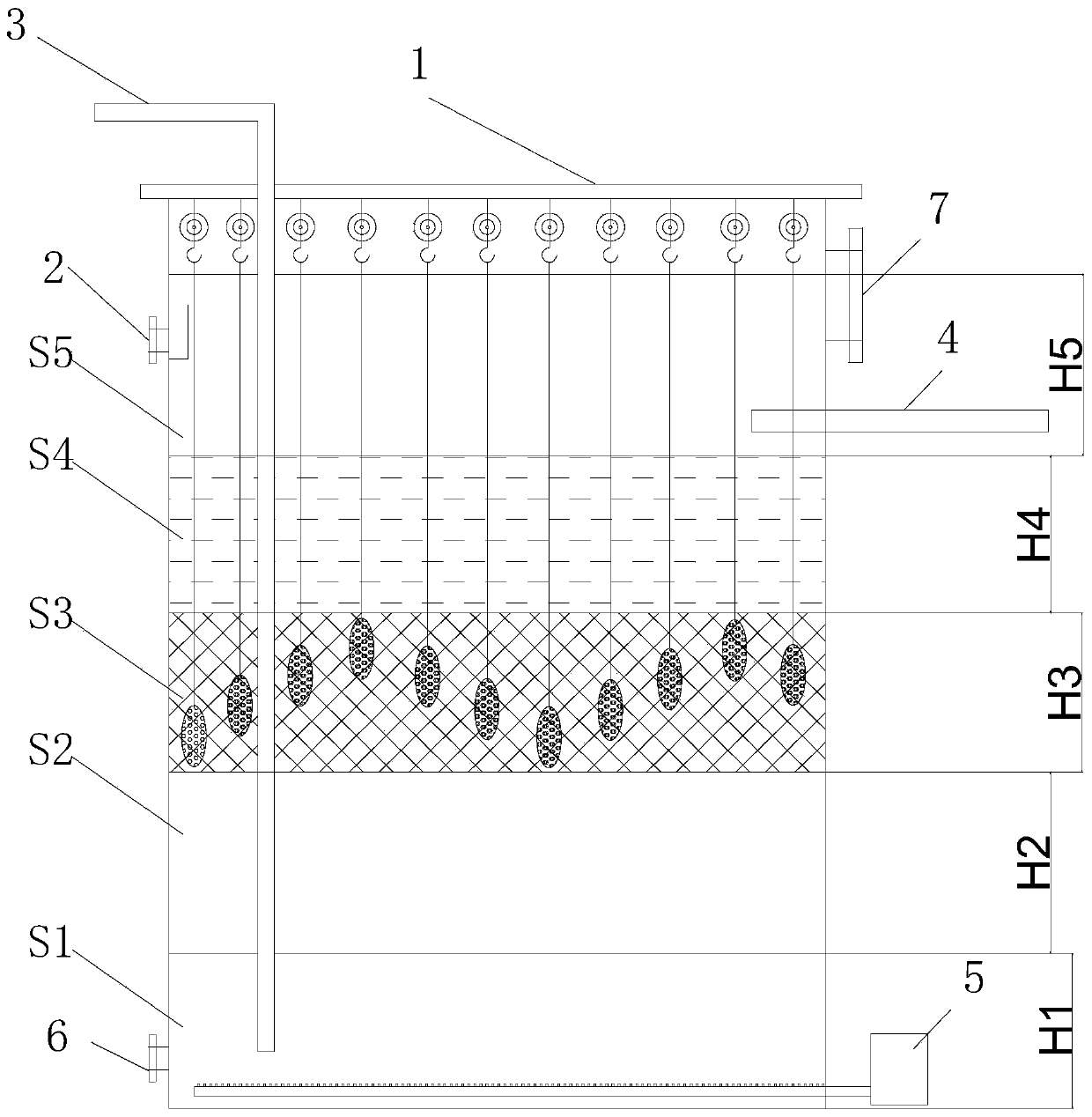

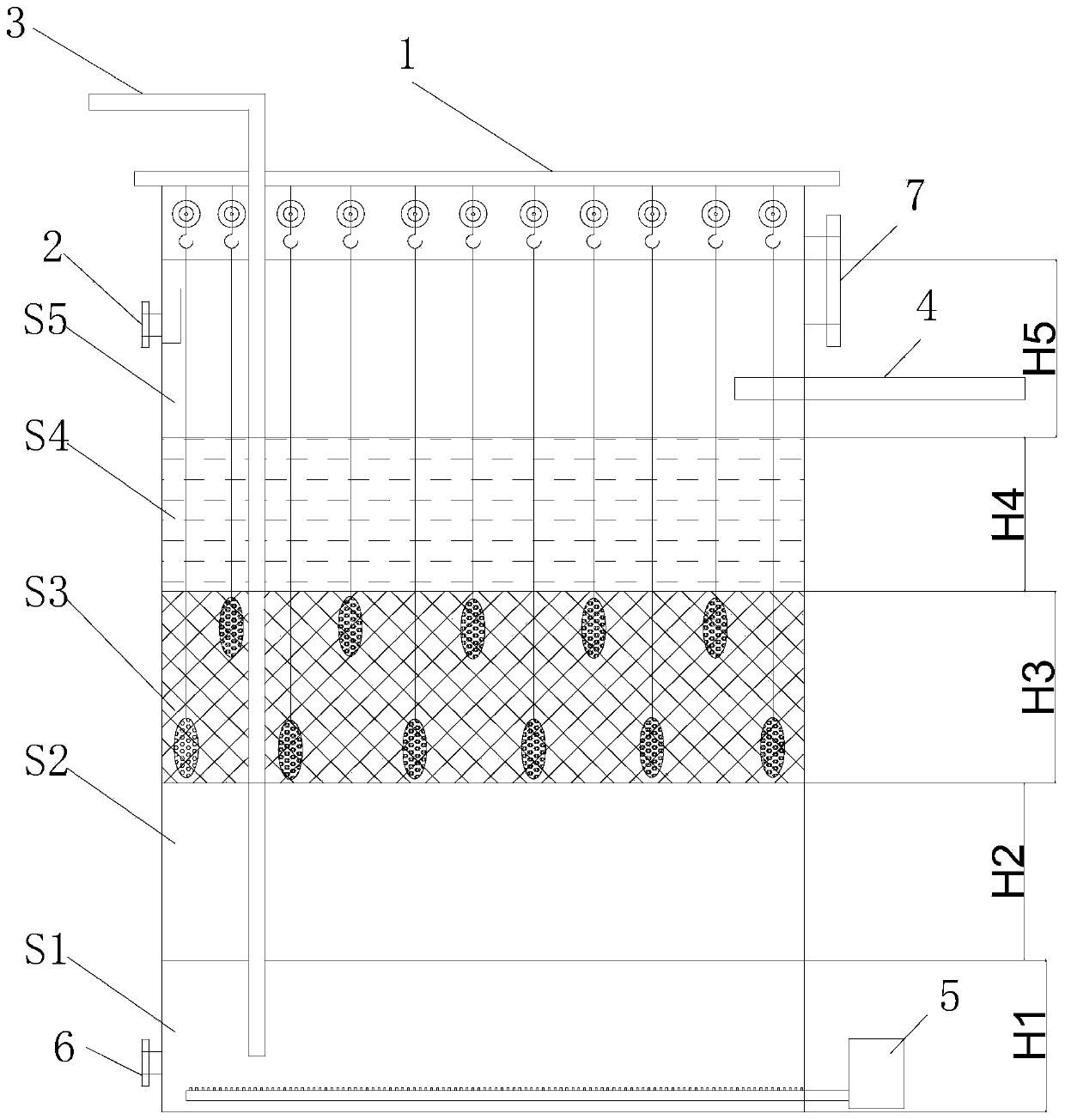

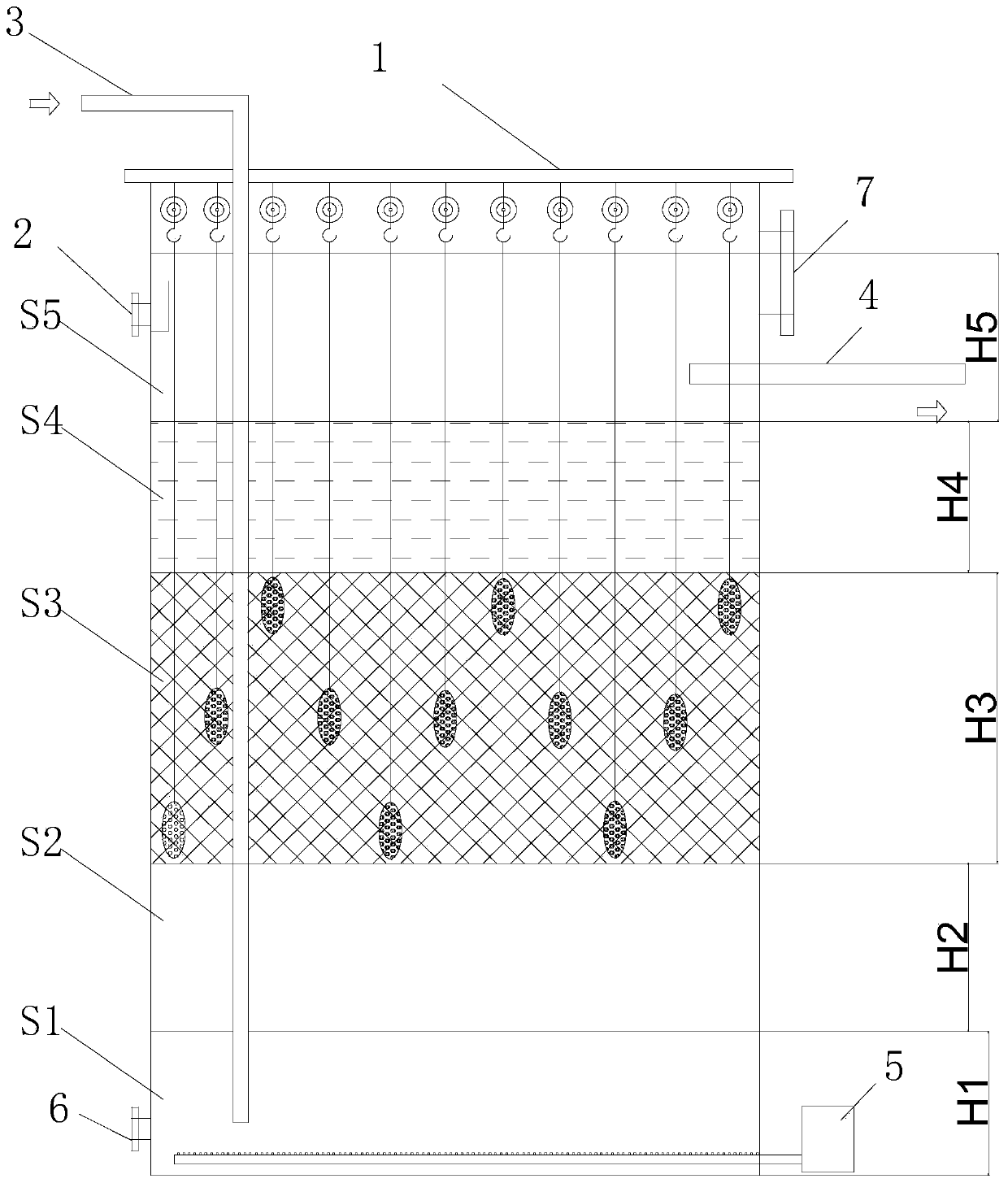

[0037] Such as Figure 1 ~ Figure 2 As shown, the sewage bioreactor with high COD and high ammonia nitrogen characteristics includes a sewage treatment tank 1 for containing sewage. The sewage depth in the sewage treatment tank is 7.5m, and the sewage treatment tank is sequentially provided with high-concentration activated sludge layers from bottom to top S1, medium concentration sludge layer S2, movable fluidized denitrification layer S3, solid-liquid separation layer S4 and clarification layer S5, the carrier 31 is set in the movable fluidized denitrification layer. The depth of the high-concentration activated sludge layer S1 is H1, the depth of the medium-concentration sludge layer S2 is H2, the depth of the movable fluidized denitrification layer S3 is H3, the depth of the solid-liquid separation layer S4 is H4, and the depth of the clarification layer S5 The depth is H5, and its height control is shown in Table 1.

[0038] Table 1 The height control of different sewage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com