Flame-retardant reinforced PBT (polybutylene terephthalate) composite and preparation method thereof

A composite material and PBT resin technology, which is applied in the field of flame-retardant reinforced PBT composite materials and its preparation, can solve the problems of large dimensional shrinkage of parts, great influence on measurement accuracy, and influence on the appearance of pressure gauges, etc., to achieve short molding cycle, Good dimensional stability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment and

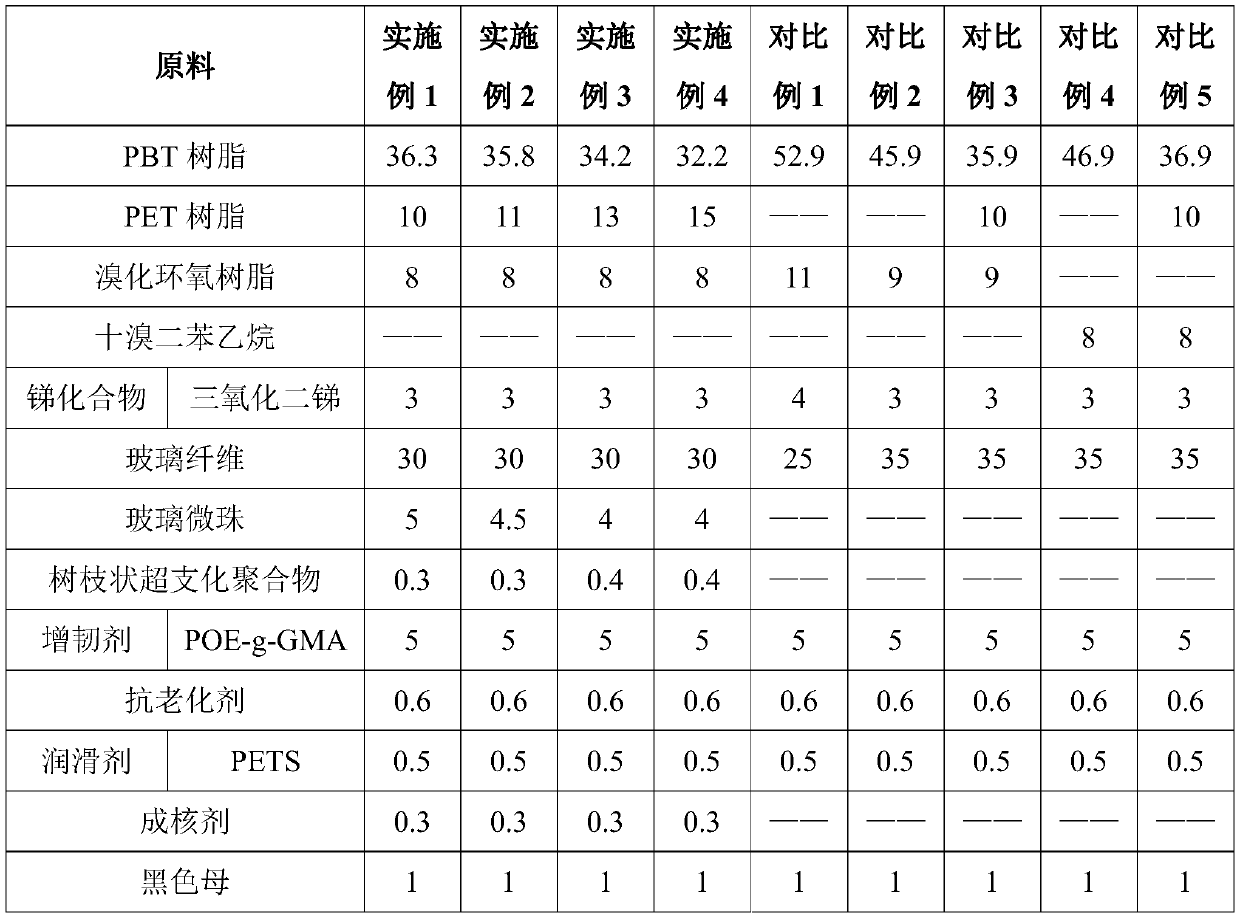

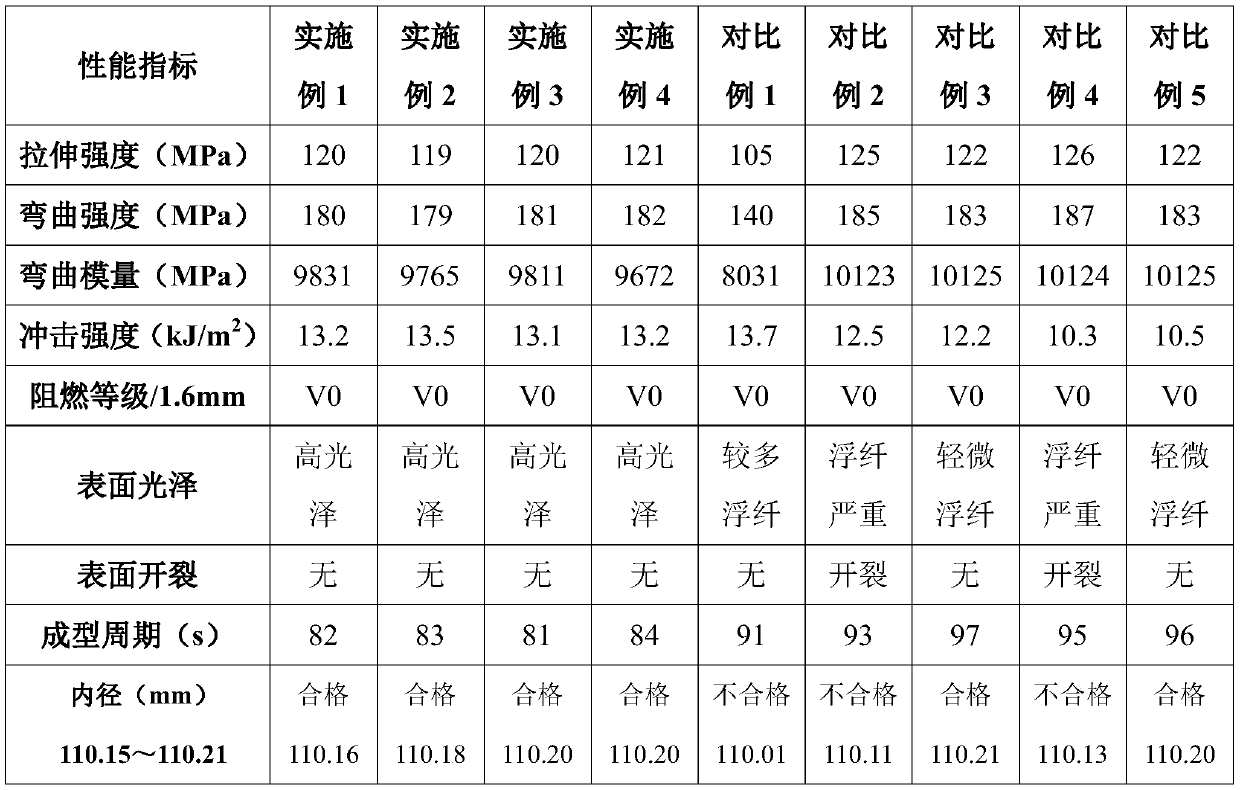

[0042] Embodiment and comparative example:

[0043] The raw material composition of the PBT composite material of embodiment 1~4 and comparative example 1~5 is as shown in the following table (according to mass percentage):

[0044] The raw material composition table (%) of the PBT composite material of table 1 embodiment 1~4 and comparative example 1~5

[0045]

[0046] Note:

[0047] The grade of PBT resin is 1200-211M, Changchun, Taiwan, China;

[0048] The grade of PET resin is TRN-8580FH, Teijin of Japan;

[0049] The grade of brominated epoxy resin is PH-116, BASF, Germany;

[0050] The grade of glass fiber (chopped strand) is ECS13-4.5-534A, Jushi Group Co., Ltd.;

[0051] The grade of glass beads is 050-20-216, French SOVITEC;

[0052] The grade of dendritic hyperbranched polymer is CYD-C600, the main component is hydroxyl-terminated hyperbranched polyester, Weihai Chenyuan Molecular New Materials Co., Ltd.;

[0053] The grade of POE-g-GMA (POE grafted glycidy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com