Antibacterial waterborne aluminum pigment and preparation method thereof

An aluminum pigment, water-based technology, applied in inorganic pigment processing, chemical instruments and methods, fibrous fillers, etc., can solve problems such as hidden dangers of paint storage and use, and reduction of aluminum pigment gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] (1) Phosphoric acid diluted with isopropanol was stirred at 30°C for 0.5h, filtered and washed to obtain washed solid aluminum powder;

[0083] (2) Disperse aluminum powder in isopropanol to obtain mixed solution A, wherein the mass ratio of isopropanol to aluminum powder is 60. Place sodium molybdate in a beaker, add deionized water and stir to dissolve it, and add it dropwise to mixed solution A. The mass ratio of sodium molybdate, ion-free water and aluminum powder is 0.03:3:1, at 50℃. After reacting for 4 hours, centrifuge to obtain a solid mixture;

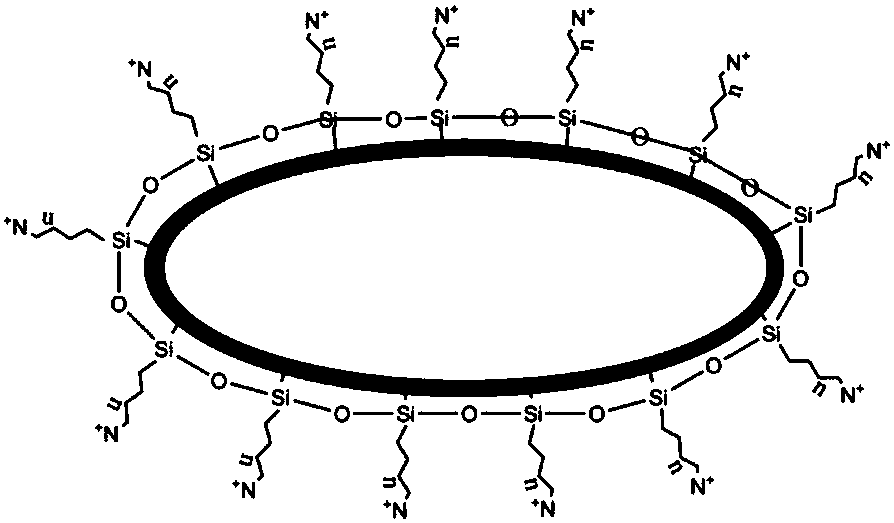

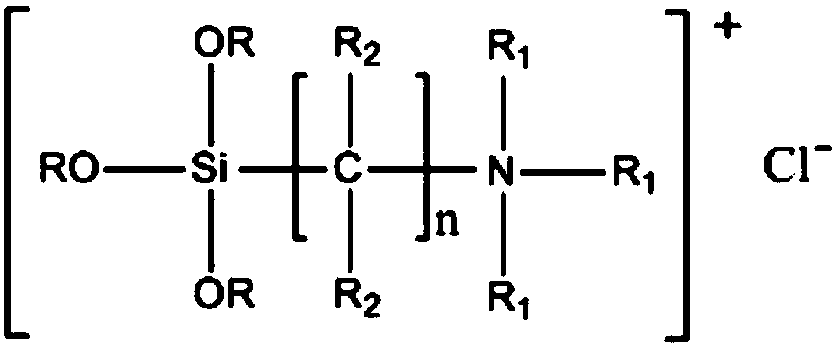

[0084] (3) Mix the solid mixture obtained in (2) with deionized water at a mass ratio of 1:5. After stirring and dispersing, add it dropwise to the quaternary ammonium salt silane coupling agent with a certain chain length, wherein the quaternary ammonium salt Silane coupling agent n=2; R=R 1 =CH 3 , R 2 =H, the mass ratio with the solid mixture and ammonia in (2) is 6:1:0.1, and after reacting at 35°C for 20 hours, the so...

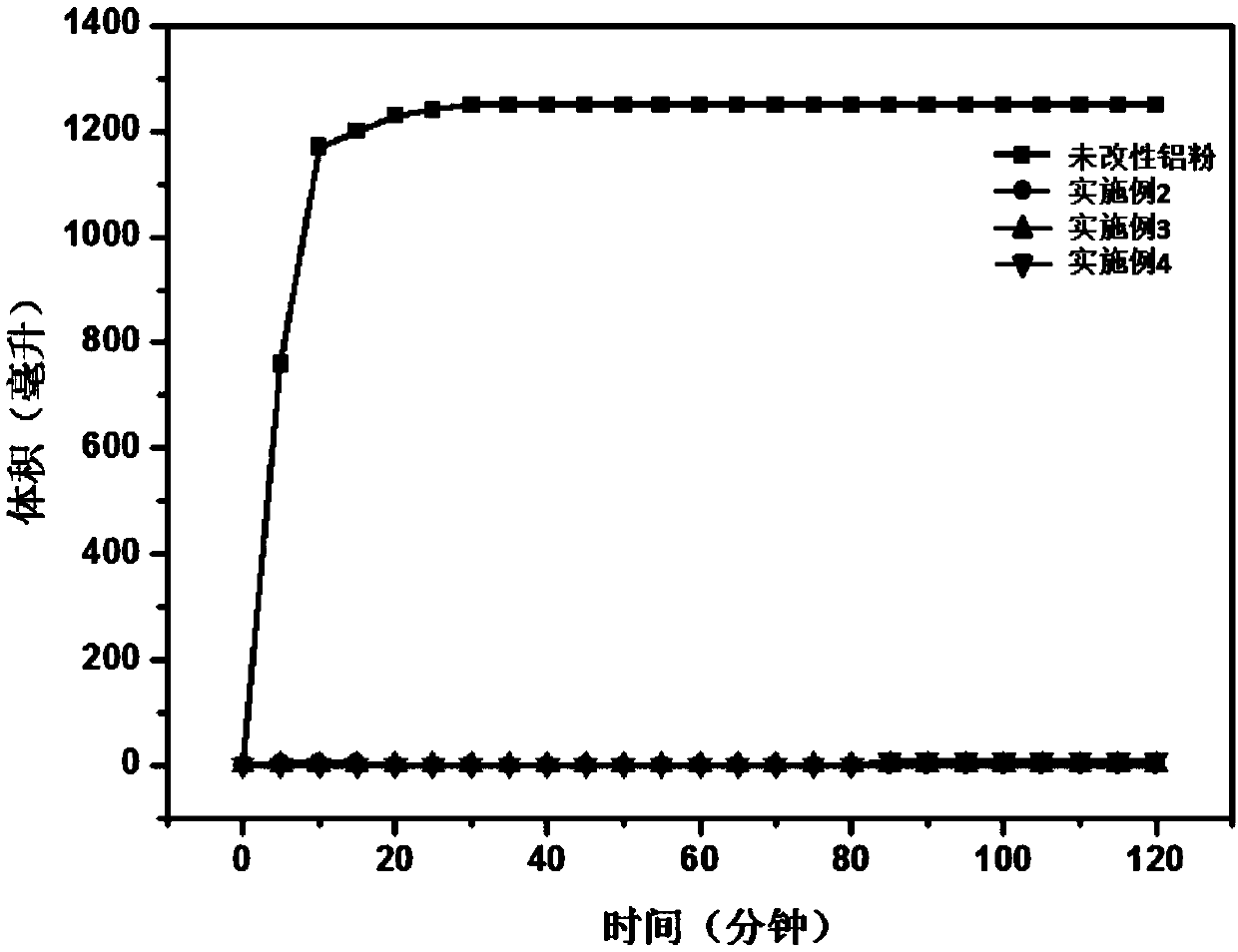

Embodiment 2

[0087] (1) Phosphoric acid diluted with n-butanol was stirred for 0.5h at 20°C, filtered and washed to obtain washed solid aluminum powder;

[0088] (2) Disperse the above-mentioned aluminum powder in n-butanol to obtain mixed solution A, wherein the mass ratio of n-butanol to aluminum powder is 35. Place the sodium polyphosphate in a beaker, add deionized water and stir to dissolve it, and add it dropwise to the mixture A. The mass ratio of sodium polyphosphate, deionized water, and aluminum powder is 0.35:2:1, at 55 After reacting for 2 hours at ℃, the solid mixture was obtained by centrifugal separation;

[0089] (3) Mix the solid mixture obtained in (2) with deionized water at a mass ratio of 1:4. After stirring and dispersing, add it dropwise to the quaternary ammonium salt silane coupling agent with a certain chain length. Silane coupling agent n=0; R=C 2 H 5 ,R1=CH 3 ,R 2 The mass ratio of =H to the solid mixture in (2) and ammonia water is 4:1:0.3. After reacting for 24 ho...

Embodiment 3

[0092] (1) Phosphoric acid diluted with butanediol was stirred at 40°C for 0.5h, filtered and washed to obtain washed solid aluminum powder;

[0093] (2) Disperse the above aluminum powder in butanediol to obtain mixed solution A, wherein the mass ratio of butanediol to aluminum powder is 55. Place the sodium polyphosphate in a beaker, add deionized water and stir to dissolve it, and add it dropwise to the mixture A. The mass ratio of sodium polyphosphate to deionized water aluminum powder is 0.35:5:1 at 55°C After reacting for 4 hours under the conditions, the solid mixture was obtained by centrifugal separation;

[0094] (3) Mix the solid mixture obtained in (2) with deionized water at a mass ratio of 1:5. After stirring and dispersing, add it dropwise to the quaternary ammonium salt silane coupling agent with a certain chain length, wherein the quaternary ammonium salt Silane coupling agent n=3; R=OH,R 1 =CH 3 , R 2 The mass ratio of =H to the solid mixture in (2) and formyl am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com