A kind of self-lubricating liquid branched polymer cutting agent and its preparation method and oil-based drilling fluid

A branched polymer, liquid technology, applied in the field of oil-based drilling fluids, can solve the problems of undisclosed applicability, etc., and achieve the effects of low bulk viscosity, improved structural strength, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

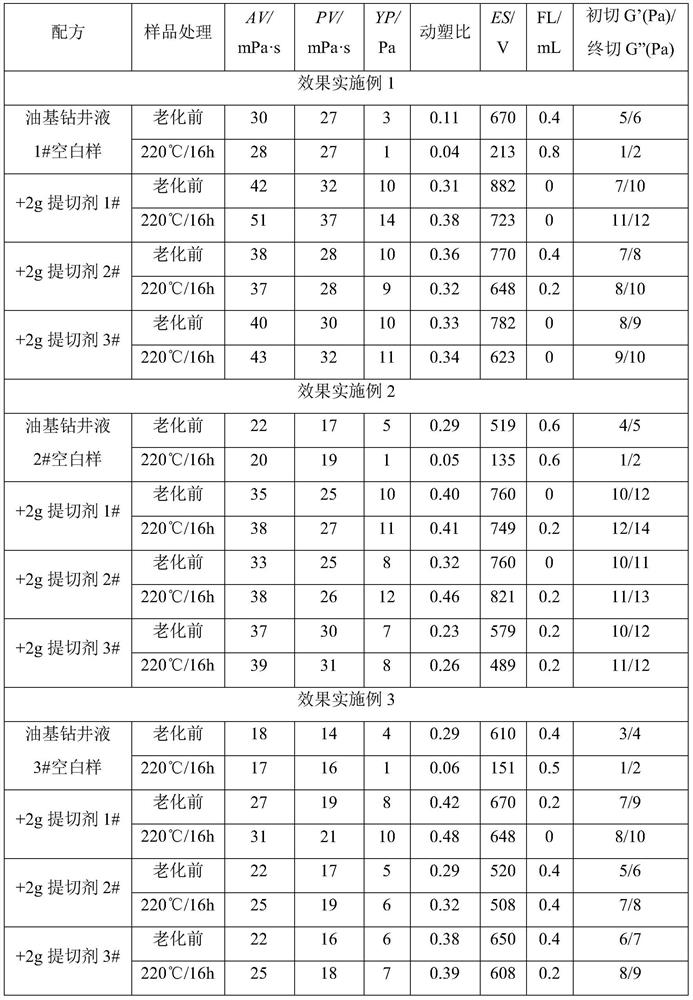

Examples

Embodiment 1

[0039] A1 is adipic acid, molecular formula C 6 h 10 o 4 , the total amount of acidic groups is x=2, and it is solid at room temperature.

[0040] B1 is phenylethanolamine, molecular formula C 8 h 11 NO 2 , the total amount of basic groups is y=3, and it is solid at room temperature.

[0041] Dissolve each of A1 and B1 in DMF (N,N-dimethylformamide) to form a 1mol / L solution.

[0042] Slowly add the above solution containing 1 / 2 mol of A1 to the above solution containing 0.2 mol of B1, control the dropwise temperature in an ice-water bath, and stir for 0.5 hours in an ice-water bath environment, during which the nitrogen atmosphere is maintained after removing air and water vapor with nitrogen; While stirring, the temperature was gradually increased to 120° C., and the first step reaction was carried out for 3 hours.

[0043] Then add the above-mentioned solution containing 0.3mol B1, add 10g KOH at the same time, raise the temperature to 150°C, and carry out the second...

Embodiment 2

[0045] A2 is trimerized linoleic acid, molecular formula C 51 h 93 -(COOH) 3 , the total amount of acidic groups is x=3, and it is liquid at room temperature.

[0046] B2 is ethylenediamine butanol, molecular formula C 10 h 24 N 2 o 2 , the total amount of basic groups is y=4, and it is solid at room temperature. Dissolve B2 in DMF to make a 1mol / L solution.

[0047] Slowly add 1 / 3 mol of A2 to the above solution containing 0.125 mol of B2, control the dropwise temperature in an ice-water bath, and stir for 1 hour in an ice-water bath environment, during which nitrogen atmosphere is maintained after removing air and water vapor through nitrogen. Under stirring, the temperature was gradually raised to 150° C., and the first step reaction was carried out, and the reaction lasted for 4.5 hours.

[0048] Then add the above-mentioned solution containing 0.3mol B2, add 20g NaOH at the same time, lower the temperature to 140°C, and carry out the second step reaction for 3 hou...

Embodiment 3

[0050] A3 is trimellitic anhydride, also known as 1,2,4-benzenetricarboxylic anhydride, molecular formula C 9 h 4 o 5 , the total amount of acidic groups is x=3, and it is solid at room temperature. Dissolve 1 / 3 mol of A3 in N,N-dimethylformamide to make a 1 mol / L solution.

[0051] B3 is diethanolamine, molecular formula C 4 h 11 NO 2 . The total amount of basic groups is y=3, and it is liquid at normal temperature.

[0052] Slowly add the above A3 solution into 0.2mol B3, control the dropwise temperature in an ice-water bath, and stir for 1.5 hours in an ice-water bath environment. During this period, the nitrogen atmosphere is maintained after the air and water vapor are removed by passing nitrogen.

[0053] Under stirring, the temperature was gradually raised to 140° C., and the first step reaction was carried out, and the reaction lasted for 2 hours.

[0054] Then add 0.3mol B3, and at the same time add 40g KOH, raise the temperature to 170°C, and carry out the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com