Oat sugarcane wine and brewing method thereof

A technology of sugarcane wine and oatmeal, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of high sugar content and lack of aroma, and achieve the effect of comfortable fruity aroma, nutritional content retention, and outstanding aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

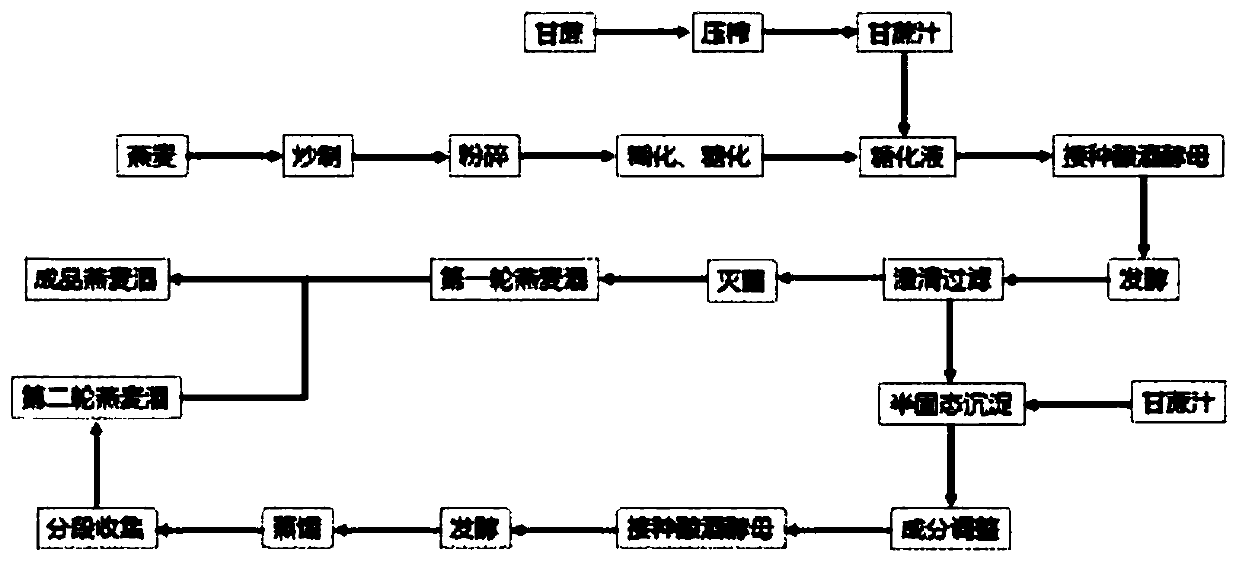

[0032] A kind of brewing method of oat cane wine, such as figure 1 shown, including the following steps:

[0033] (1) Raw material selection: oat grains are full and complete, without mildew or moth, and uniform in color; purple-skinned sugarcane is uniform in thickness, bright in color, with hoarfrost, the darker the color, the better, and free of moth.

[0034] (2) Raw material processing: Bake oatmeal in the oven at 120°C for 20 minutes until it produces a burnt aroma, crush until the meat is rotten and the skin is not rotten, add 4 parts of water to 1 part of oatmeal, cook in a pressure cooker at high temperature for 15 minutes, and cool to Adjust the pH to 4.5 with citric acid at 66°C, add 0.2 parts of α-amylase to 1 part of oats, and saccharify for 4 hours to obtain saccharified mash; wash the sugarcane and press to obtain sugarcane juice;

[0035] (3) Composition adjustment: mix the saccharification mash and sugarcane juice according to the volume ratio of 1:1, then ad...

Embodiment 2

[0042] (1) Raw material selection: oat grains are full and complete, without mildew or moth, and uniform in color; purple-skinned sugarcane is uniform in thickness, bright in color, with hoarfrost, the darker the color, the better, and free of moth;

[0043] (2) Raw material processing: Bake oatmeal in an oven at 130°C for 15 minutes until it produces a burnt aroma, crush until the meat is rotten and the skin is not rotten, add 5 parts of water to 1 part of oatmeal, cook in a pressure cooker for 15 minutes at high temperature, and cool to Adjust the pH to 5.0 with citric acid at 66°C, add 0.3 parts of α-amylase to 1 part of oats, and saccharify for 4 hours to obtain saccharified mash; wash the sugarcane and press to obtain sugarcane juice;

[0044] (3) Composition adjustment: mix the saccharification mash and sugarcane juice according to the volume ratio of 1:1.5, then add white sugar to adjust the final sugar content to 25°Bx, adjust the pH to 4.0 with citric acid, and obtain ...

Embodiment 3

[0051] (1) Raw material selection: oat grains are full and complete, without mildew or moth, and uniform in color; purple-skinned sugarcane is uniform in thickness, bright in color, with hoarfrost, the darker the color, the better, and free of moth;

[0052] (2) Raw material processing: Bake oatmeal in an oven at 150°C for 20 minutes until it produces a burnt aroma, crush it until the meat is rotten and the skin is not rotten, add 4 parts of water to 1 part of oat flour, cook in a pressure cooker for 15 minutes at high temperature, and cool to At 67°C, adjust the pH to 5.0 with citric acid, add 0.2 parts of α-amylase to 1 part of oats, and saccharify for 4.5 hours to obtain saccharified mash; wash the sugarcane and press to obtain sugarcane juice;

[0053] (3) Composition adjustment: mix the saccharification mash and sugarcane juice according to the volume ratio of 1:1, then add white sugar to adjust the final sugar content to 20°Bx, adjust the pH to 4.0 with citric acid, and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com