Operation control method of wind power generation and hydrogen production hydrogen storage system

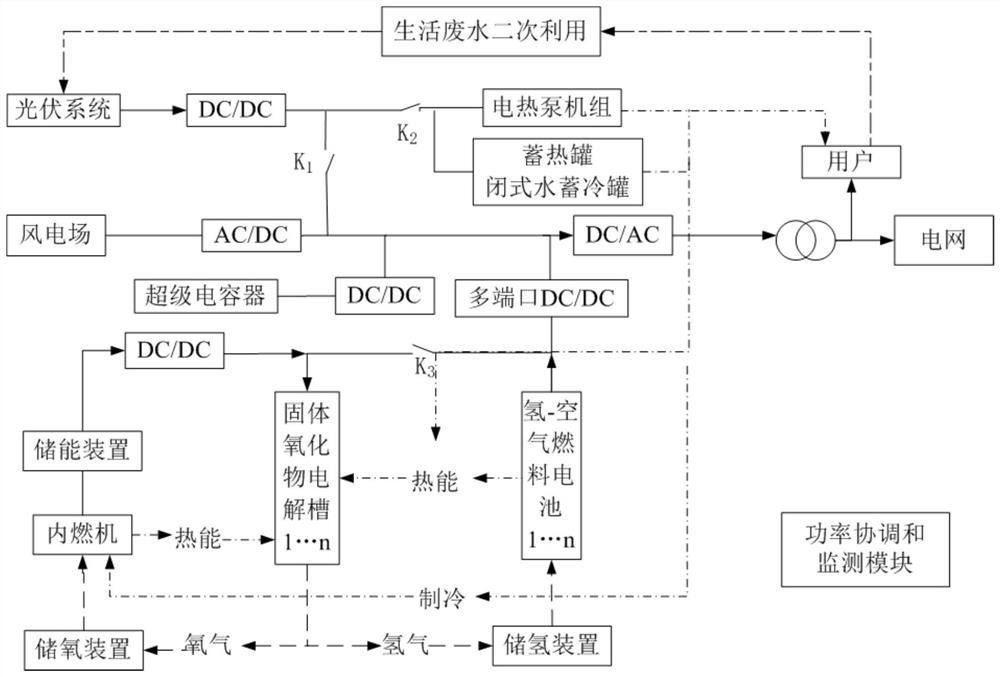

A wind power generation and operation control technology, applied in wind power generation, photovoltaic power generation, current collectors, etc., can solve problems such as large impact on the power grid, uneven hydrogen production, and short service life of equipment, and achieve strong peak-shaving capability of the system and high energy utilization rate High, to ensure the smooth effect of hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

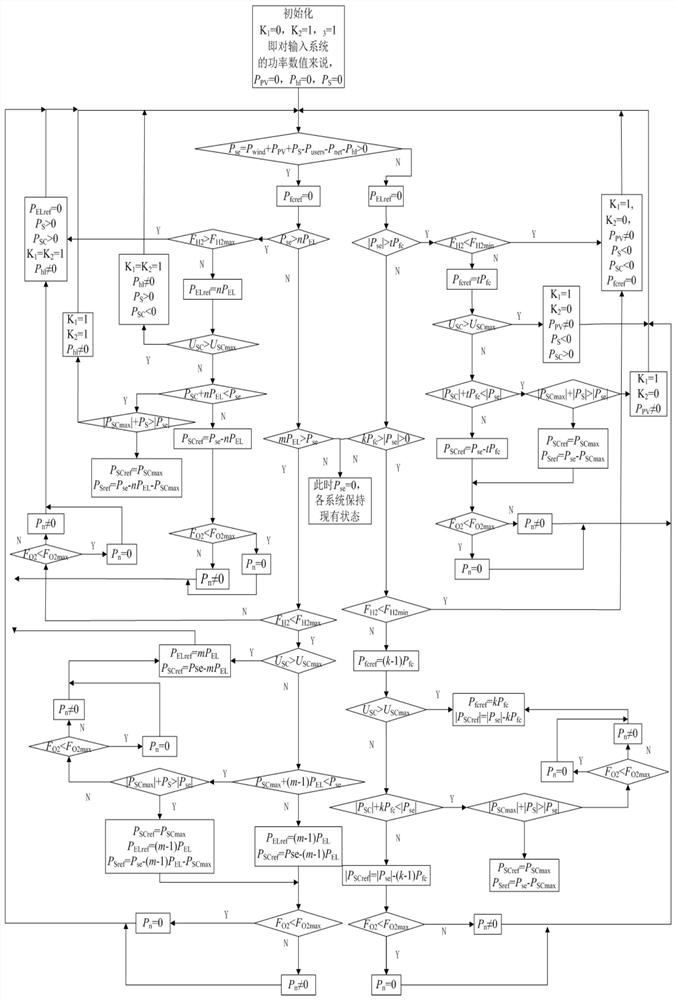

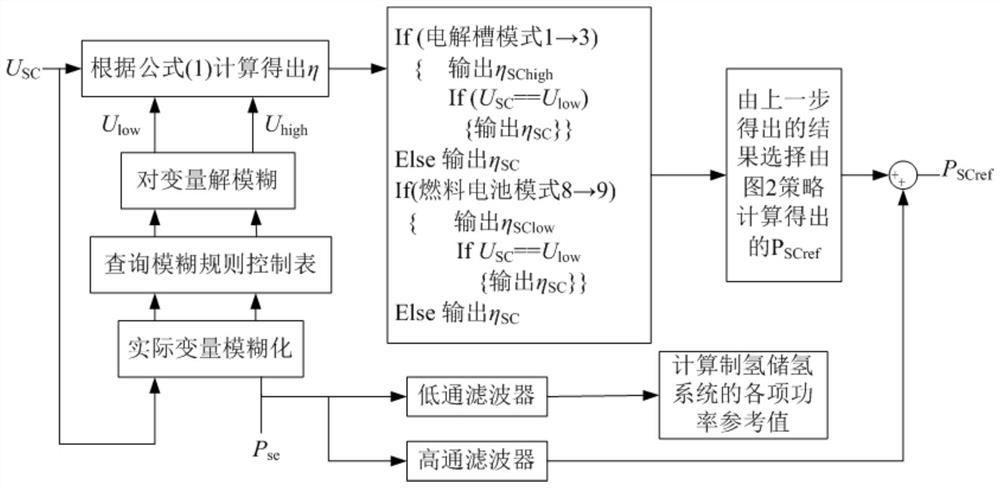

[0058] As a specific embodiment provided by the present invention, preferably, it is characterized in that it includes the following steps:

[0059] A. Establish low-bandwidth communication between the controllers of each converter and the power coordination control module and monitoring module: the controllers of each converter adopt an adaptive PI controller to collect monitoring data of each monitoring system. The monitoring data includes the following Some or all of them: wind farm power, superior power grid dispatching power, cooling and heating system power, user power, photovoltaic system power, overall power of solid oxide electrolyzer group / hydrogen fuel cell group, oxygen storage / hydrogen tank pressure, The power and state of charge SOC of the energy storage device, the voltage and power of the supercapacitor; the above monitoring data are connected to the input interface of the ARM processor in turn, and the output port of the power reference value of each part is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com