A kind of heterogeneous gradient composite material and its preparation method

A technology of composite materials and aluminum-based composite materials, which is applied in the field of heterogeneous gradient composite materials and their preparation, can solve the problems affecting the thermal and mechanical properties and process performance of electronic packaging materials, difficult to control thickness, etc., and achieve good sintering performance and easy Control and reduce the effect of forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

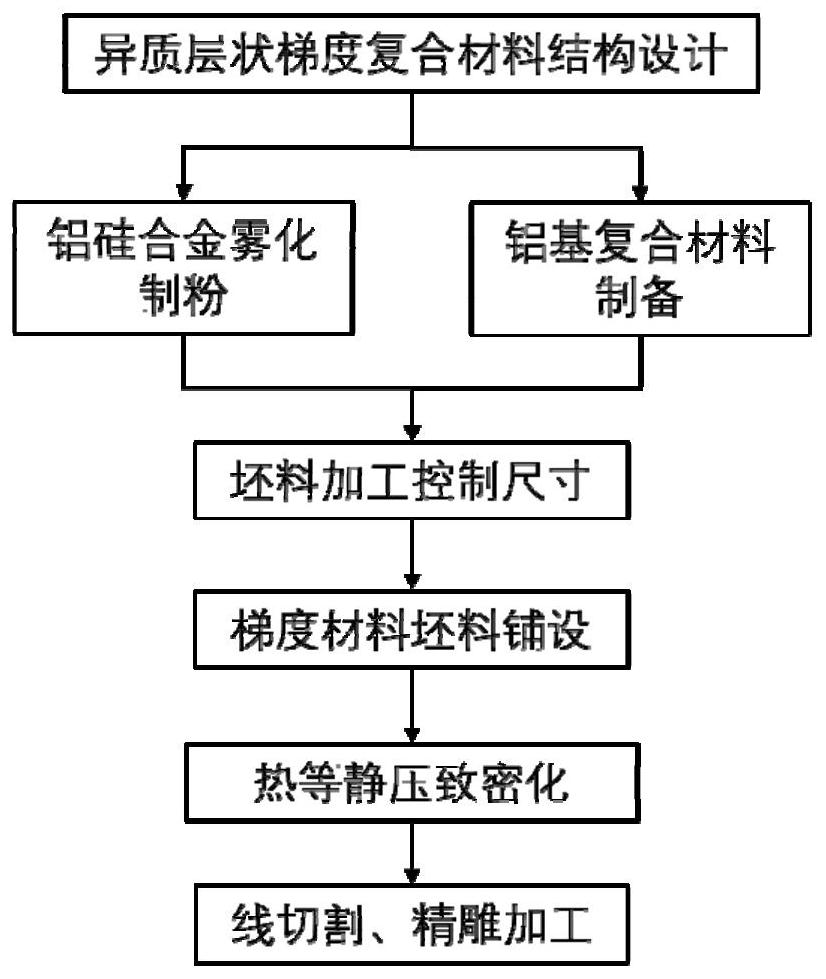

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment 1, Al-42%Si / Al-50%diamond twins are made of silicon-aluminum alloy Al-42%Si with a silicon weight percentage of 42% and an aluminum-based composite material Al-50% diamond with a weight percentage of 50%. layer heterogeneous gradient composite material, the specific steps are as follows:

[0029] (1) Preparation of silicon-aluminum alloy powder

[0030] The invention adopts a gas atomization method to prepare aluminum-silicon alloy powder. Select pure aluminum ingots and monocrystalline silicon blocks as raw materials, and mix the pure aluminum ingots and monocrystalline silicon blocks with a proportion of silicon content of 42% and the balance as aluminum in terms of weight percentages, and then mix the weighted Pure aluminum ingots are sent to an intermediate frequency induction melting furnace for melting. The tundish crucible of the intermediate frequency induction melting furnace is heated by resistance. The preheating temperature is between 700...

Embodiment 2

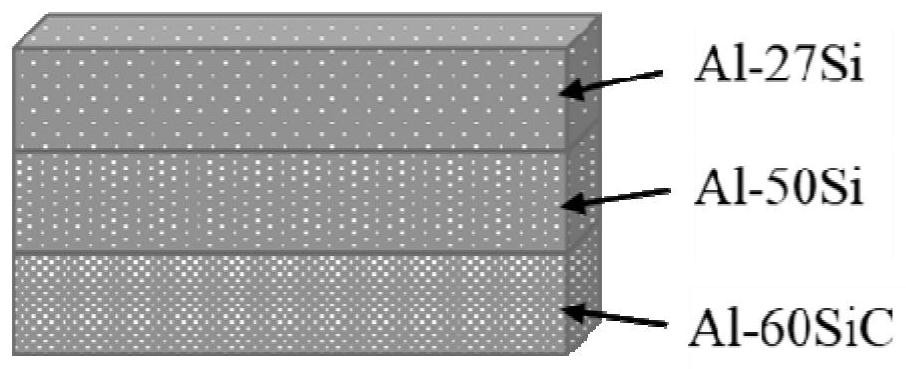

[0038] In the present invention, the Al-27% aluminum alloy Al-27% Si, Al-50% Si and SiC with a weight percentage of 60% SiC are used to make Al-27% Si / Al-50%Si / Al-60%SiC three-layer heterogeneous gradient composite material, the specific steps are as follows:

[0039] (1) Preparation of silicon-aluminum alloy powder

[0040] In Example 2, the method for preparing silicon-aluminum alloys Al-27%Si and Al-50%Si powders with silicon weight percentages of 27% and 50% respectively is the same as step (1) in Example 1.

[0041] (2) Synthesize aluminum matrix composites and make them into slabs

[0042] The SiC preform and the Al-(3-12)%Si-(0.3-1.0)%Mg alloy matrix are prepared according to the SiC weight percentage of 60%. Put the SiC preform in the graphite mold, then put the Al-(3~12)%Si-(0.3~1.0)%Mg alloy matrix on the SiC preform, put them all into the infiltration furnace; vacuum to 10 -3 Pa, heated to 780-860°C, kept warm for 10-30min, filled with argon to 2.5-3.0MPa, kept war...

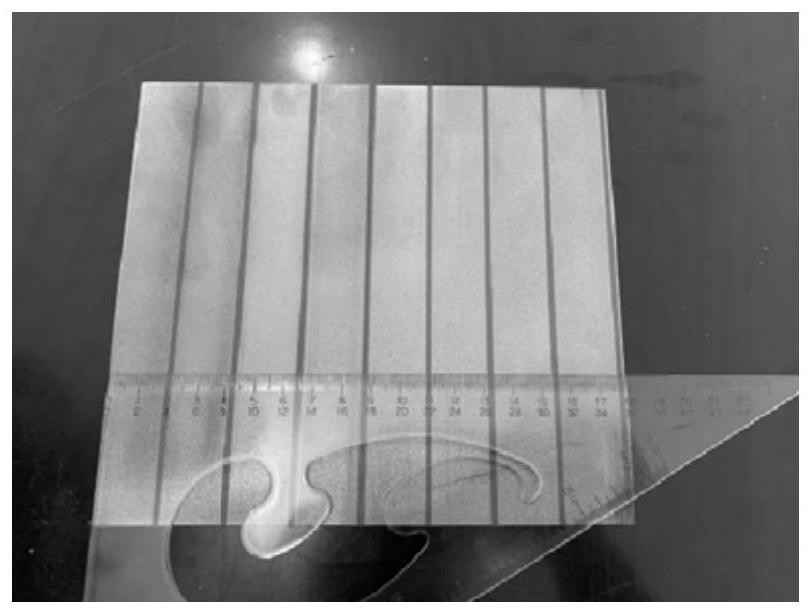

Embodiment 3

[0050] The preparation of heterogeneous gradient functional materials is mainly to make the adjacent materials tightly bonded. The bonding force between materials mainly comes from external pressure and heat. If the external pressure is too large, the thickness of the composite material layer will be difficult to control. If the pressure is too small, the bond may not be firm and cracks may appear. Therefore, the applicant tries to adjust the internal structure of the aluminum matrix composite material or the aluminum silicon alloy, and increases the bonding force from the inside to the aluminum matrix composite material and the aluminum silicon alloy, hoping to make the aluminum matrix composite material and the aluminum silicon alloy under lower pressure. The alloy is closely combined, which not only ensures the controllable thickness of the aluminum matrix composite material layer, but also does not appear cracks.

[0051] Taking the preparation of the Al-42%Si / Al-50%diamon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com